Hi Rainer

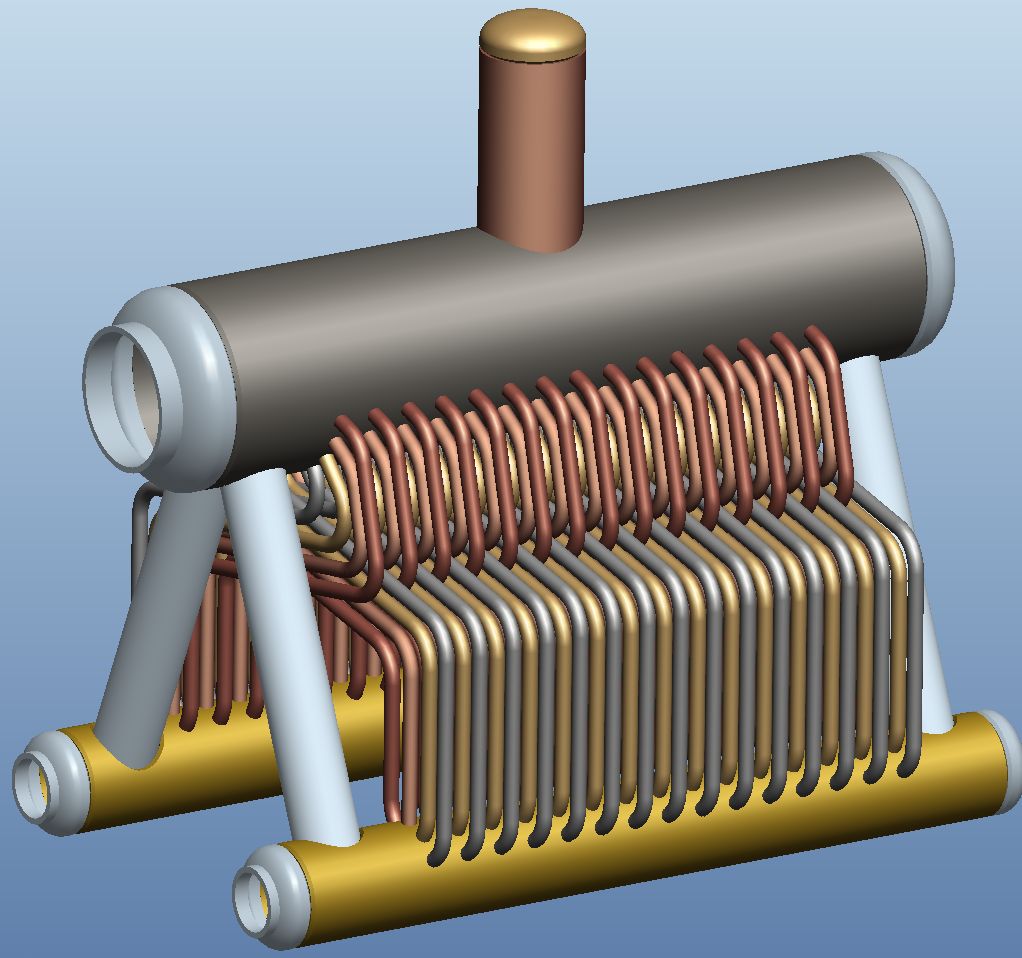

I do like your CAD drawings. That looks vaguely like the Yarrow style pressure vessel that I am attempting to turn into a boiler (Long boring story not for the Forum!).

For various reasons (all daft

) I actually have two pressure vessels and casings, so I have been trying to work out which one to use. My key question, like the perennial question about how much steam/water does a given engine use, is how does one work out the effective heating surface area of the pressure vessel?

I have looked at the Steamboating Guide (SBA) and it would appear that one should use 75% of the surface area of the tube and drums. I have assumed that the ends of the drums can be ignored as they are usually embedded in insulation or disappear into blow down or feed valves. However, I seem to be coming up with much a smaller figures for the one boiler for which I have drawings and a stated figure for effective heating surface. As you can imagine, I am a bit puzzled.

So do you, or any of the Forum Fellows have any thoughts to add?

Regards

Pete