Page 2 of 2

Re: First Wate Test

Posted: Tue Jul 03, 2012 11:30 pm

by johnp

Thanks Fred, I referred to a lot of your posts. I'm in Ontario and just built a little steamboat for the the cottage. I won't be in NY, my shaft is 1" straight bore, do you think I can make a sleeve? I'd like to try your prop. Since my prop was repitched and dug out of a barn I don't have a lot of faith In what the gentlemen told me the pitch was. The blades are quite narrow which would lead me to believe I would experience a lot of slip since the reduced surface area.

Re: First Water Test

Posted: Wed Jul 04, 2012 12:32 am

by fredrosse

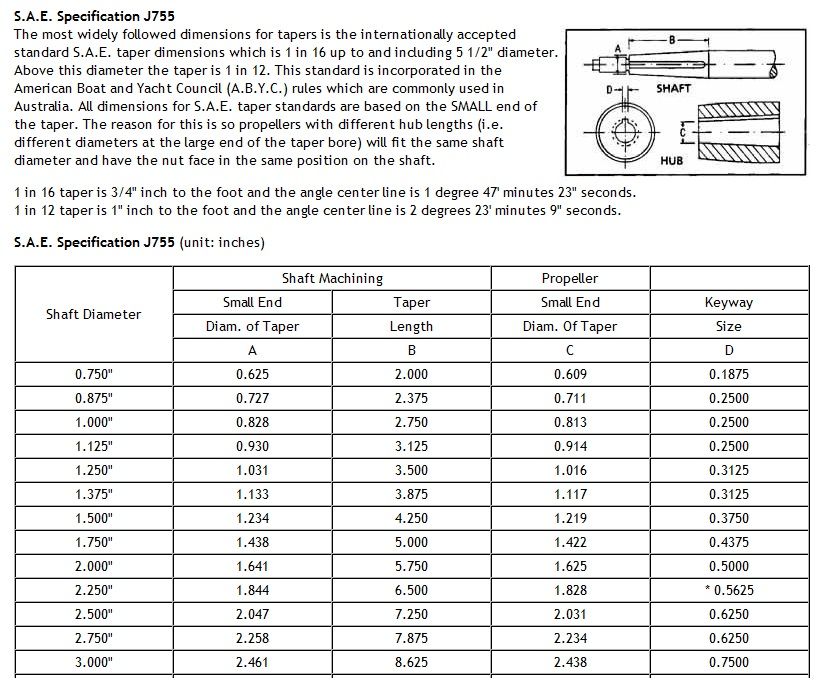

The prop tapered bore is 1.187 inch diameter on the big end, 1.015 diameter on the small end, length thru hub is 2.750. Keyway is 0.312 wide x 0.125 deep. With the moderate power of tour engine I would think a sleeve could be made OK. Never sent anything to Canada, but will do this if you want. I know there will be some Canada steamboats at Waterford this weekend probably. Anyone know of who might be there and able to take the prop back to Ontario??

Re: First Water Test

Posted: Wed Jul 04, 2012 2:43 am

by Chris W

Check with a propellor shop for a bushing. I've seen them made of plastic and they worked just fine. You will need a non standard sized key to make up for the thickness of the bushing.

Congrats on your maiden voyage!

Re: First Water Test

Posted: Wed Jul 04, 2012 7:41 am

by Johnlanark

You've put together a beautiful boat and it looks to go well too - congratulations. I'm sure you'll enjoy tuning the plant to the best performance in the next little while. John

Re: First Water Test

Posted: Wed Jul 04, 2012 2:06 pm

by fredrosse

For a 1” straight shaft, this is the bushing you need.

I am assuming you have a key on your shaft, either 1/4” or 5/16 inch to take the torque of driving the propeller. A key is necessary here to take the torque of the drive shaft. The set screws hold the bushing to the shaft, and probably need a small countersink on the shaft to allow the set screws to bite properly. These set screws take all of the propeller thrust force, so some countersinking where the screws bed down is prudent. The prop and key then go onto the bushing, followed by the fairwater nut on the end of the drive shaft. Lightly tightening the fairwater nut will push the propeller onto the tapered fit, and off steaming you go.

Some alternates you might consider temporarily, use ordinary shaft collars and just make the tapered part of the bushing shown on the attached drawing.

If you do not have a threaded shaft for a fairwater nut, then you can use an ordinary shaft collar again here. Without the fairwater nut to press the prop onto the bushing, use removable Loctite (Thread Locker Glue) to put things together. Just clean everything, apply Loctite, assemble the parts as firmly as you can, tighten the collar set screws, and let things stand overnight.

As far as materials for these parts, Bronze would be the first choice, ordinary steel is a reasonable alternate.

This setup is not for the kind of power that the propeller is capable of absorbing (well over 100 horsepower), but it is ok for a couple of horsepower at a few hundred RPM as is your application.

Re: First Water Test

Posted: Wed Jul 04, 2012 3:25 pm

by DetroiTug

Another method with good results as well. A tapered sleeve with an inner taper which is standard for 1" prop shafts. Drove the sleeve up tight on the 1" propshaft then put a 5/16" solid steel pin (not shown) through the whole assembly in the middle.

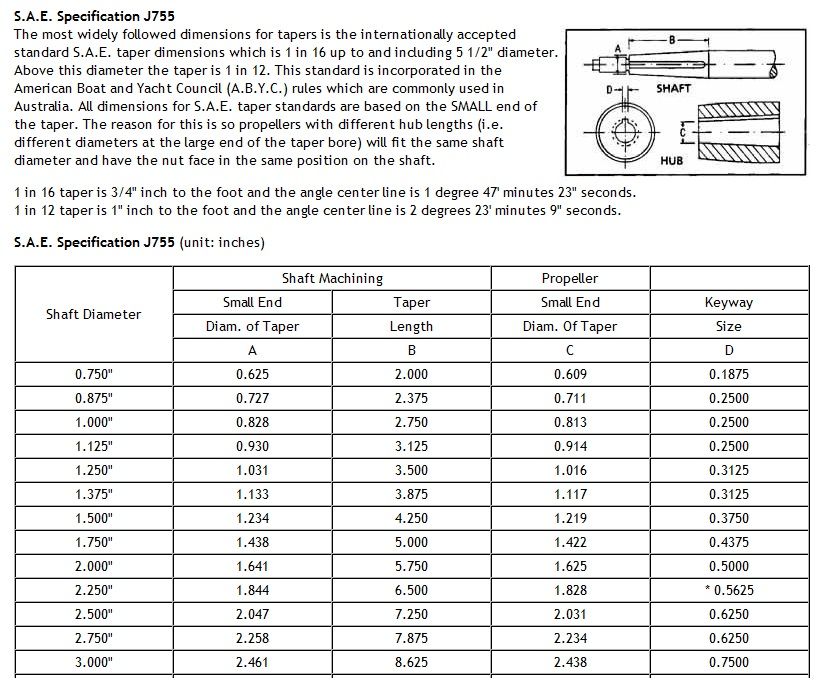

Below are the taper standards.

-Ron

Re: First Wate Test

Posted: Tue Jul 10, 2012 12:46 am

by johnp

fredrosse wrote:I happen to have a 14 RH 17 Michigan DYNA-JET Prop that was on my electric boat, 1-1/4 shaft, standard marine taper. It is a good 3 blade bronze prop, with a few minor dings & scrapes. I will lend it to you for tryout, if you want it then you can buy it from me, or return via the mail. Being close to what you may need, a 17 inch pitch, it would be a good canidate for re-pitching if needed.

Fred, PM sent