Page 7 of 8

Re: Southworth 12" Vertical pumps

Posted: Tue Jun 18, 2013 6:06 pm

by Lopez Mike

Interesting. I am familiar with forced draft from years of locomotive practice. But I have never heard of getting any boost from an annular tube outside the funnel. Where did you get the idea?

Folly is an open launch so my stack is single wall. I've thought of insulating it to keep the gasses hot and get more natural draft. Right now I'm poking about the internet to find a dial thermometer to monitor the stack gasses. I'm not sure what a reasonable top reading needs to be. 600F? 1000F? Wood fire. Normally natural draft. Maybe a blower in the future.

Mike

Re: Southworth 12" Vertical pumps

Posted: Tue Jun 18, 2013 6:36 pm

by DetroiTug

Mike,

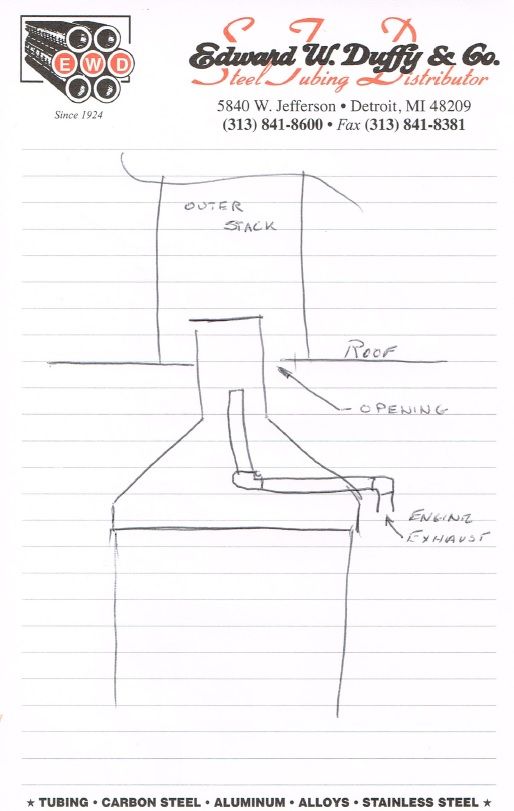

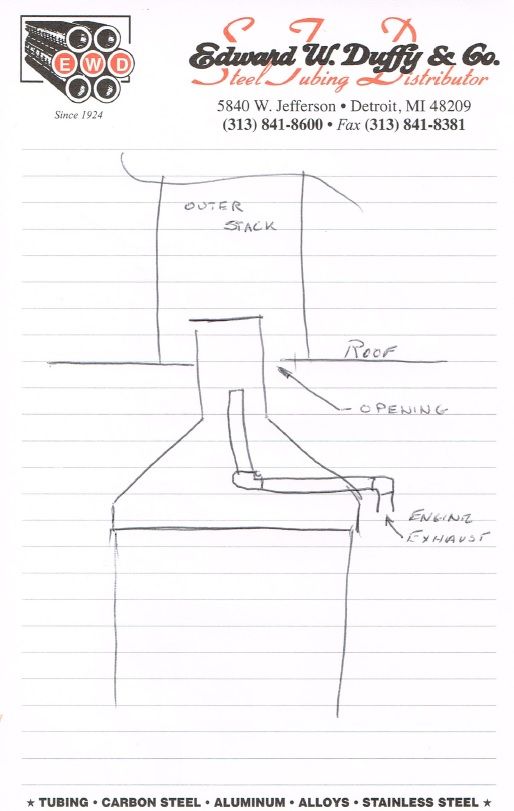

I'm not sure the outer stack is adding any boost although it may be since it is removing warm air which is creating a negative pressure, which means it may be pulling on the inner stack a bit.

I've been checking my funnel temperature with the infrared and it has never been over 300 degrees, usually like 280 er so. Most of the heat is being absorbed in to the boiler water. Seems that is optimum - anything close to the steam temperature, can't get anything more usable out of it.

-Ron

Re: Southworth 12" Vertical pumps

Posted: Tue Jun 18, 2013 10:15 pm

by Rainer

On Emma's boiler I have a thermometer from 0 - 500°C. It is common in Germany for house hold heating systems. You get it with a 150, 300, 400 or even 500 mm long heat sensor - all without battery what fits best to steamboating

http://www.ebay.de/sch/i.html?_odkw=rau ... r&_sacat=0

Have a look here:

Or a close look here

It shows only 160°C stack temp here. This is because we had some barbecue in the wood fire before:

During normal operation the stack temp varied from 280 up to 350 °C

Re: Southworth 12" Vertical pumps

Posted: Tue Jun 18, 2013 10:19 pm

by Lopez Mike

Ah! I am headed to a stove store now.

Thank you,

Mike

Re: Southworth 12" Vertical pumps

Posted: Tue Jun 18, 2013 10:47 pm

by Lopez Mike

Rainer,

I see that your thermometer is near the bottom of the stack. Do you think that is the best place? Or should it be higher up?

Mike

Re: Southworth 12" Vertical pumps

Posted: Wed Jun 19, 2013 2:03 pm

by Rainer

I wanted to know the hot air temp. around the not water cooled boiler surfaces to estimate the heat load in the material.

Today the German TÜV like to see this thermometer at this place. The temp. here should not come over 450°C because this is the temp. what the material strength was calculated for (strange English?).

Additional here is the last point where the air temp. generates some steam. The stack temp. varies according to the stack insulation but did not tell you anything about the possible heat transfer from the hot air through the boiler walls into your water/steam...

Re: Southworth 12" Vertical pumps

Posted: Wed Jun 19, 2013 10:26 pm

by Lopez Mike

Very good. Your English is fine. You should not want to hear my German! German is reasonably logical. English has stolen words from everyone. Powerful but unpredictable. Like the crazy U.S.

The thermometer has been ordered. 550F max (~300C). I will install it low in the pipe. Perhaps in the cone from the boiler to the stack. $8 USD on line. It has probe that will extend well into the hot gasses.

Mike

Re: Southworth 12" Vertical pumps

Posted: Wed Jul 10, 2013 7:41 am

by Bob Cleek

Lopez Mike wrote:Ah! I am headed to a stove store now.

Thank you,

Mike

You might consider one of these woodstove flue thermometers. I had one once on a woodstove and it worked fine. There are two types. One has a stem which is inserted into the flue through a drilled hole. (Looks like a meat thermometer.) This one has a magnet on the back and simply sticks to the iron flue pipe and can be removed, or moved up and down the flue to check the temp in various areas, or on the stove itself. They are dirt cheap, less than $25. It ain't a fancy brass cased number, but it works fine.

Re: Southworth 12" Vertical pumps

Posted: Sun Jul 14, 2013 3:35 pm

by DetroiTug

Update on the Southworth

Just got back from the Mid-Michigan steamboat meet. Ran for three days, used the Southworth continually; automatically and reliably kept the boiler water right below the middle trycock. We were giving rides and starting and stopping a lot. Coming in to the dock, the pump was left running and it kept the boiler calmed down no matter how big the fire was. It continually pulls hot water/steam out and replaces it with 172 degree feedwater.

The tug holds steam pressure better on on long runs now too. It is continually putting water in at about the same rate of consumption. Slower feed velocity allows the heat exchanger and economizer to work more efficiently. It just runs and all I have to do now is keep the fire going and watch the glass. It was a big hit at the show. Sitting dockside it sounds like an idle locomotive.

-Ron

Re: Southworth 12" Vertical pumps

Posted: Mon Aug 05, 2013 6:41 pm

by JonRiley56

Hi,

I have a question about the exhaust line on this little pump. I set up intially with the exhaust from the pump dumping into my hotwell but would prefer to have it routed into my regular exhaust so that my hotwell is a little less "active". The exhaust on my engine is running at about 15 psi or so I believe. Do I need to put a check valve in line on the pumps exhaust to keep the exhasut pressure from the engine from interfering with the pump ?

thanks !

jon