Olfelt

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

Re: Olfelt

I would make sure you have several inches of vertical steam space; this will help keep water out of the engine. I'd just have the steam dome be a piece of 3" or 4" pipe sticking into the stack.

- Bart

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Olfelt

Ron,

Great work!

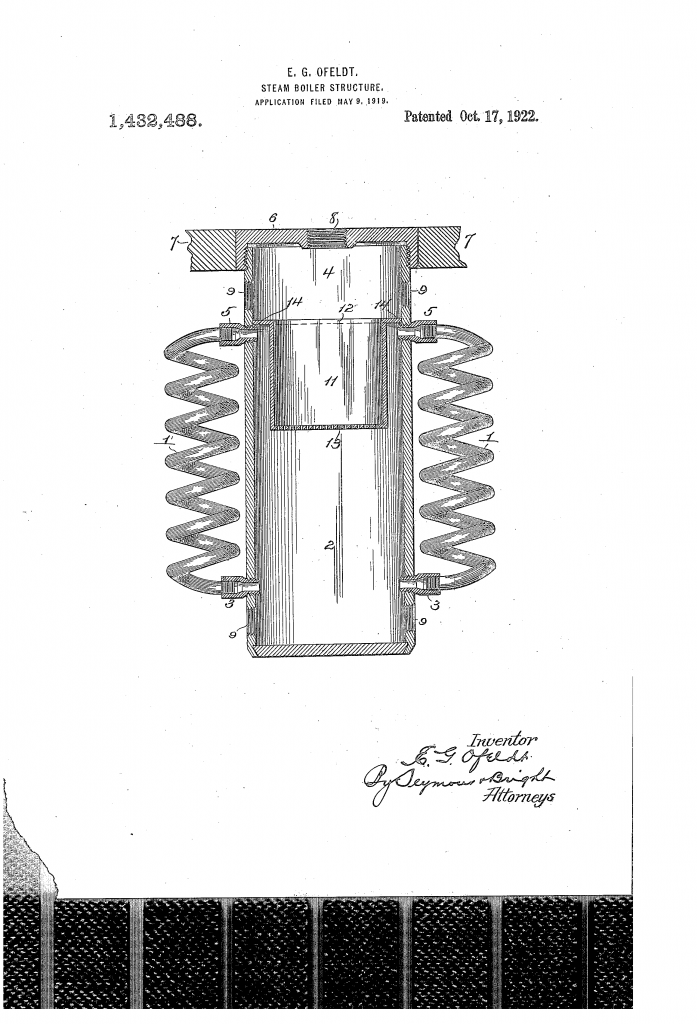

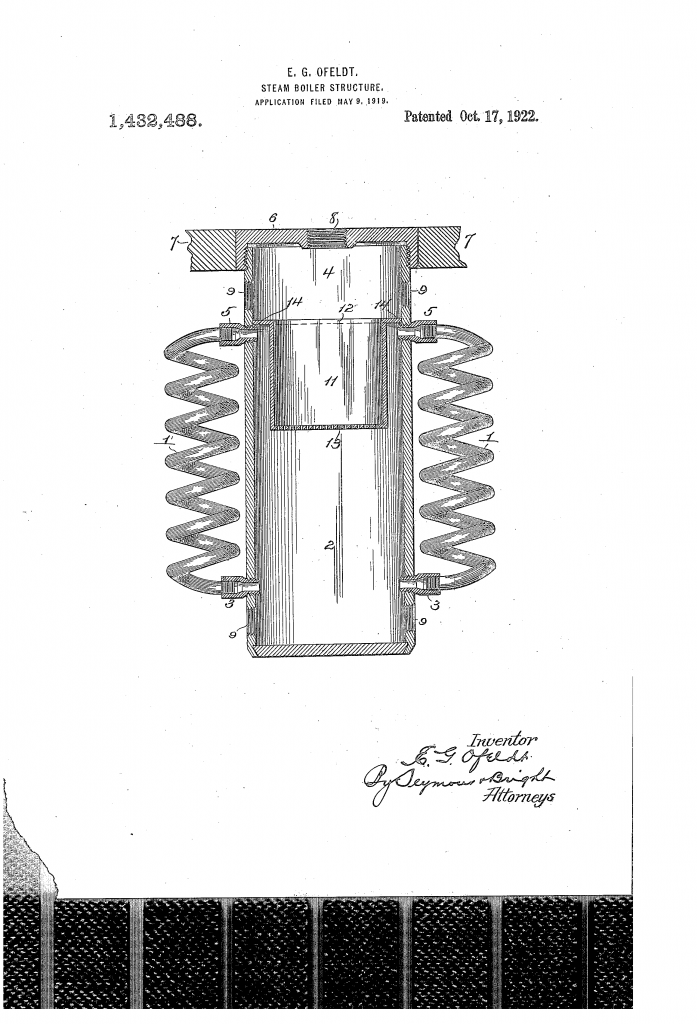

Boat boilers can have the carry over troubles too, especially when blowing whistles/sirens, sudden acceleration/ over filling feedwater etc. The Ofeldt is pretty good about not succumbing to carry over conditions. Although, some precaution needs to be taken to prevent it. One is as Bart mentions, extend the center drum height a sufficient distance. Another way is a combination internal deflector/steam dome as I did on mine. A third method is a deflector only, as my friend did on his (auto use). His deflector is simply a large flat washer type plate under the steam outlets with a 1" hole in the center, that works too. On mine (auto use)I went closer to the original Ofeldt patent, whereby the short steam dome extends down in to the center drum and past the exits of the generation tubes. Water/steam exits the generation tubes at high velocity under hard firing. The internal tube deflects everything down and only steam comes back up to the outlets if the water level is maintained. I've only experienced carry over once when I manually overfilled the boiler while driving.

The Ofeldt is capable of making steam very quickly and maintaining demand. Here is a video firing up my car. Keep in mind this is a very hot kerosene fire, but it will make steam from cold in about a minute from main burner ignition. I joked the other day,. that if I get this firing up any faster I'm going to start casting doubt on the electric starter

-Ron

Great work!

Boat boilers can have the carry over troubles too, especially when blowing whistles/sirens, sudden acceleration/ over filling feedwater etc. The Ofeldt is pretty good about not succumbing to carry over conditions. Although, some precaution needs to be taken to prevent it. One is as Bart mentions, extend the center drum height a sufficient distance. Another way is a combination internal deflector/steam dome as I did on mine. A third method is a deflector only, as my friend did on his (auto use). His deflector is simply a large flat washer type plate under the steam outlets with a 1" hole in the center, that works too. On mine (auto use)I went closer to the original Ofeldt patent, whereby the short steam dome extends down in to the center drum and past the exits of the generation tubes. Water/steam exits the generation tubes at high velocity under hard firing. The internal tube deflects everything down and only steam comes back up to the outlets if the water level is maintained. I've only experienced carry over once when I manually overfilled the boiler while driving.

The Ofeldt is capable of making steam very quickly and maintaining demand. Here is a video firing up my car. Keep in mind this is a very hot kerosene fire, but it will make steam from cold in about a minute from main burner ignition. I joked the other day,. that if I get this firing up any faster I'm going to start casting doubt on the electric starter

-Ron

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

Re: Olfelt

My Lune Valley style boiler (like an Olfelt w/ lots of small coiled tubes but each making only three turns before reentering the drum) has much more problem with the water level lifting when blowing the whistle, etc. This is likely due to the introduction of steam-laden lower density water in the bottom portion of the drum by the lower tubes. When I build another pressure vessel for Otter (the current one is now 20 years old), it will likely be an Olfelt.

- Bart

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

- TahoeSteam

- Full Steam Ahead

- Posts: 813

- Joined: Fri Mar 07, 2014 5:38 am

- Boat Name: Wayward Belle

- Location: South Lake Tahoe, CA, USA

- Contact:

Re: Olfelt

Silly old man falls asleep everywhere. I distinctly remember being at a friends birthday party when I was 5 and he was asleep on their couch with a teddy bear!

Ron,

I'm liking your work! any interest in making a second?

Ron,

I'm liking your work! any interest in making a second?

~Wesley Harcourt~

https://www.youtube.com/c/wesleyharcourtsteamandmore

https://www.youtube.com/c/wesleyharcourtsteamandmore

-

ron parola

- Steam on Deck

- Posts: 55

- Joined: Fri Jan 29, 2016 3:56 am

- Boat Name: victoria

Re: Olfelt

Let's see if this works out first!! Am winding a superheater coil and have wound up an economiser coil, Waiting for some more sch 80 fittings. I'll probably leave the old boiler in untill after the B&W meet and will swap out during the winter. Hopefully will have the boiler done in another month or so ( Hey I've retired; no rushing!). Hydro next and will see IF it makes any steam, I'm hoping for 150 psi on the pilot light!.... well maybe not. cheers rp

-

ron parola

- Steam on Deck

- Posts: 55

- Joined: Fri Jan 29, 2016 3:56 am

- Boat Name: victoria

Re: Olfelt

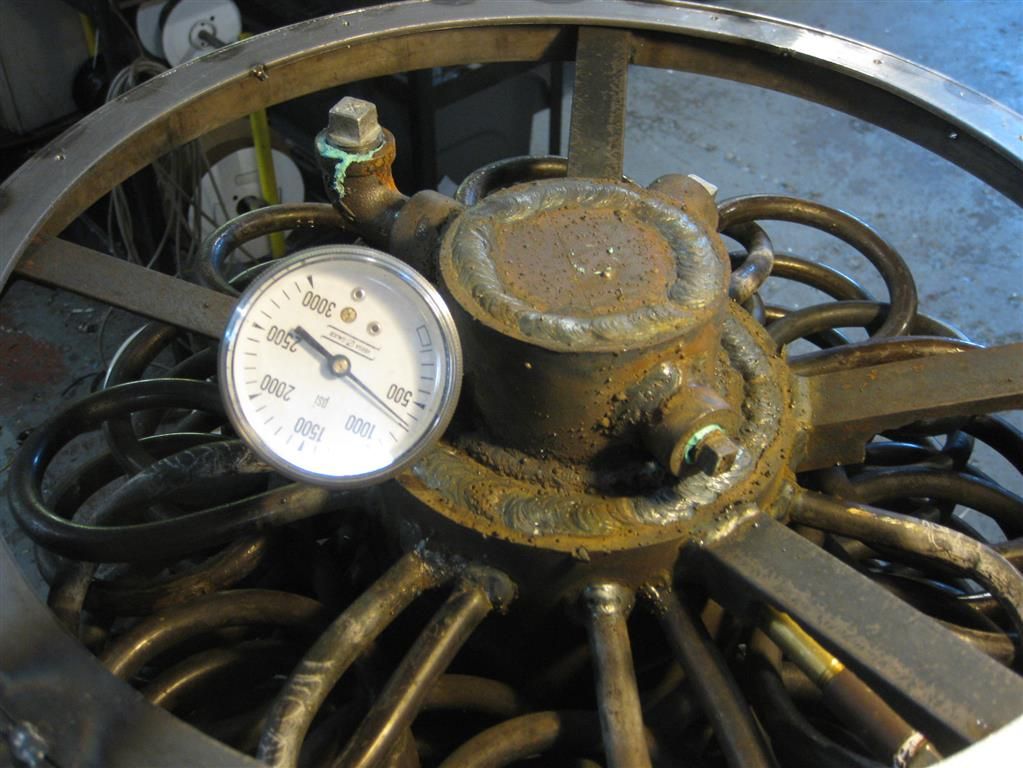

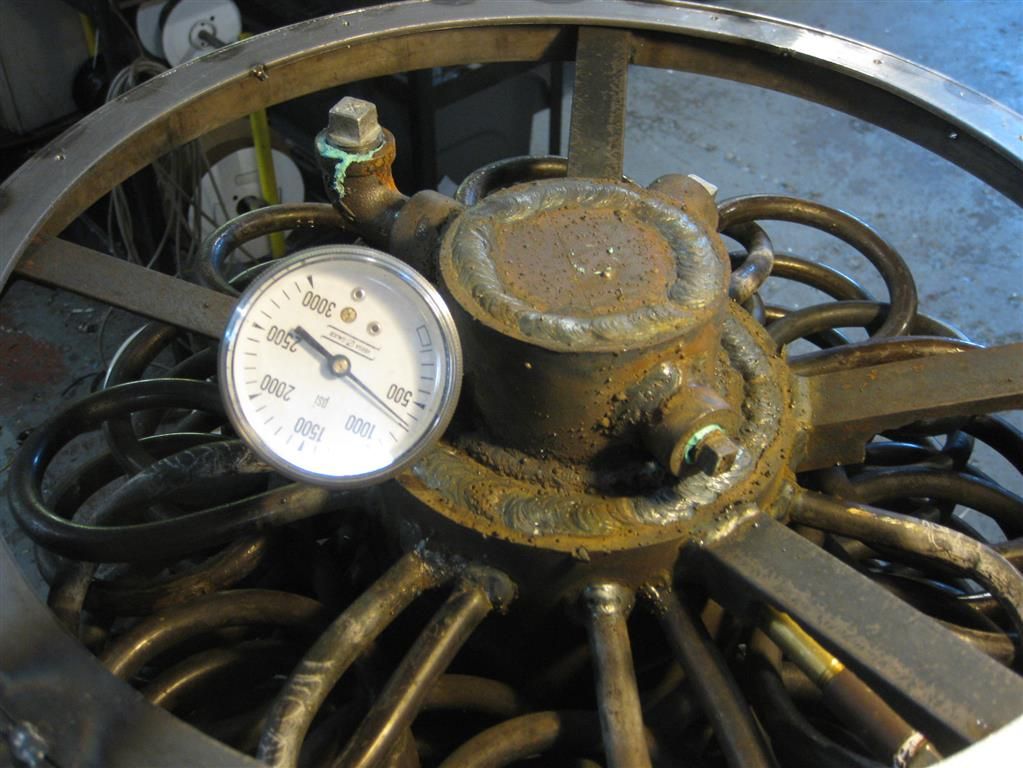

Back at it, a cruise down the Petaluma river, fibreglassed the interior of my water tank and rationalized some under floor plumbing, now doneish with boiler. Finished last big welds yesterday, the hottest day this year!, and pressure tested it this AM. Some plumbing oozes, of which all but one were dealt with, the 2in pipe cap at the top can't be tightened further cuz the boiler spins, will wait on that untill the boiler is bolted down. Pumped it up to 375 psi but pump ck valve leaked a bit and it dropped to 360 before I could shut the main valve off. And there it's been sitting all morning; NO LEAKS. All welding done except for top sheetmetal and smoke hood mounts, I'm going to wait on those because I don't know the interior measurements of the one on my current boiler, I may be able to reuse it. There is a superheater ( more like a drier) under there and there are mounts for the economiser towards the top about 20ft, but room to double it, that's why there is a pipe coupler up top; to be able to remove the economiser coil if needed, yes it could go above all the plumbing but I'm TRYING to keep the CG low. Next step; firebox, trying to think of a way that I can roll a one ft tall 20in dia cylinder out of 3/16th steel. And any thoughts on castable refractory vs SS liner with insulation a la Stanley? Cheers ronp

- Attachments

-

- DSCF2422 small.JPG (101.84 KiB) Viewed 10361 times

-

- DSCF2420small.JPG (93.79 KiB) Viewed 10361 times

-

- DSCF2415 small.JPG (122.73 KiB) Viewed 10361 times

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

Re: Olfelt

I've tried both.And any thoughts on castable refractory vs SS liner with insulation a la Stanley? Cheers ronp

A tangentially directed fire is very hot, and over time (years) will distort the stainless, even if you make it from the fancy (and $$$) 310 or 321 stainless. On Stanley steamers the fire doesn't hit the stainless. If your burner avoids this, stainless may well work for you.

Castable is heavier but longer lasting; the guys making metal melting oil furnaces have shown us the way here. I'm using Mizzou castable refractory; it seems to shrug off both the direct fire and the shocks of trailering very nicely.

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

-

ron parola

- Steam on Deck

- Posts: 55

- Joined: Fri Jan 29, 2016 3:56 am

- Boat Name: victoria

Re: Olfelt

castable ordered; my original firebox is cement of some sort and is almost 40 years old and is in fine shape. Just trying to cool things down in the cockpit, possibly fibrefax BETWEEN sheetmetal outer wall and refractory lining? rp

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

Re: Olfelt

Yup; my entire boiler is surrounded by stainless jacket, 1" Fibrefrax and outer stainless jacket. The firebox has another 1" of fiber and then the refractory lining. Firebox area is coolest part of boiler.ron parola wrote:castable ordered; my original firebox is cement of some sort and is almost 40 years old and is in fine shape. Just trying to cool things down in the cockpit, possibly fibrefax BETWEEN sheetmetal outer wall and refractory lining? rp

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

-

ron parola

- Steam on Deck

- Posts: 55

- Joined: Fri Jan 29, 2016 3:56 am

- Boat Name: victoria

Re: Olfelt

Boiler doneish, now getting to firebox. MORE questions; I've been taking combustion air from the ashpit door on the original boiler with a baffle to keep it from blowing against the flame and pushing it to one side. So I was thinking about having a series of holes in the side of the firebox, maybe 6, at or above the level of the fire. Since there will be refractory cast in there the holes would be actually tubes almost 2in long. Any rules of thumb regarding air intake vs stack size and height dimensions? I'm burning #2 diesel and usual fuel flow is just about 3 gallons an hour

- Attachments

-

- IMG_20160706_103928135sm3.jpg (125 KiB) Viewed 10252 times