Steam engine from the North Caucasus

- TahoeSteam

- Full Steam Ahead

- Posts: 813

- Joined: Fri Mar 07, 2014 5:38 am

- Boat Name: Wayward Belle

- Location: South Lake Tahoe, CA, USA

- Contact:

Re: Steam engine from the North Caucasus

You may not be able to make an olefeldt watertube boiler with tubes that size, but you could possibly make a Babcocks and Wilcox or a Worthington style watertube boiler. Both have good circulation characteristics and have been used in marine applications. We have a Worthington style in our large boat, and B&W boilers have been used extensively in soups of all sizes.

- Attachments

-

- images (16).jpeg (20.64 KiB) Viewed 331276 times

~Wesley Harcourt~

https://www.youtube.com/c/wesleyharcourtsteamandmore

https://www.youtube.com/c/wesleyharcourtsteamandmore

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Steam engine from the North Caucasus

Here is an original George Whitney boiler that belongs to a friend of mine. The engine that went with this boiler was purchased by Webster out east of aluminum launch hull fame. The engine castings were copied and sold to a few people.

A boiler design you may consider with larger tubing and limited means to bend it, is the porcupine boiler.

This Whitney boiler uses right and left hand threads.

-Ron

A boiler design you may consider with larger tubing and limited means to bend it, is the porcupine boiler.

This Whitney boiler uses right and left hand threads.

-Ron

-

Freezerrr12

- Warming the Engine

- Posts: 96

- Joined: Tue Aug 25, 2020 6:36 pm

- Boat Name: Anastasia

Re: Steam engine from the North Caucasus

Dear TahoeSteam and DetroiTug, I thank you for your feedback and your recommendations. I have already seen the boiler design recommended by TahoeSteam. This is a great design, but it requires a lot of welding work that I can't handle, I can't do it, I'm a very poor welder. If not for this, I would have started building this particular boiler. DetroiTug showed me a porcupine steam boiler that I have never seen. But I cannot understand how steam is generated and circulated in such a steam boiler? Where is the top of such a boiler? Where should the firespace be located? The second George Whitney boiler is a very nice interesting steam boiler that interested me. But I cannot imagine in what sequence it should be assembled and what kind of seal between bends and straight threaded tubes should be used? To what extent will such connections be vapor tight? Making such a boiler from the material that I have seems to me difficult, but possible. I also want to thank the other enthusiasts who gave me the recommendations and again I want to ask the question: have any of you used a steam box (zolotnik). one, as I showed in the photo, with one port for steam outlet? How does this design work? I would be grateful for advice and any information.

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Steam engine from the North Caucasus

Quote ''porcupine steam boiler that I have never seen. But I cannot understand how steam is generated and circulated in such a steam boiler?''

Porcupine boilers have poor natural internal circulation and why they are not very popular. They do work as some have been built and used over the years. I was reading somewhere that a flat thin plate is installed horizontally in the tubes, creating circulation from the lower half to the upper half of the tubes.

With limitations on welding access and access to machines to roll form tubing, there are only going to be very few design options available. The porcupine is the only boiler that I can think of. It could be constructed with no welding by selecting a heavy wall thickness of the center drum and threading right in to it.

Whatever design you choose, post it here and let some of us have a look to help.

Get the book ''steamboats and modern steam launches'' some very good information on boilers.

-Ron

Porcupine boilers have poor natural internal circulation and why they are not very popular. They do work as some have been built and used over the years. I was reading somewhere that a flat thin plate is installed horizontally in the tubes, creating circulation from the lower half to the upper half of the tubes.

With limitations on welding access and access to machines to roll form tubing, there are only going to be very few design options available. The porcupine is the only boiler that I can think of. It could be constructed with no welding by selecting a heavy wall thickness of the center drum and threading right in to it.

Whatever design you choose, post it here and let some of us have a look to help.

Get the book ''steamboats and modern steam launches'' some very good information on boilers.

-Ron

-

steamboatjack

- Full Steam Ahead

- Posts: 283

- Joined: Fri Nov 20, 2009 8:02 am

- Boat Name: grayling

- Location: Cumbria U.K.

Re: Steam engine from the North Caucasus

Your picture above shows a “piston valve” very common on locomotives, this particular one has a hollow body so that the upper and lower sections are common, exhaust from the upper ports can therefore leave via the lower exhaust port.

It is usual practice to use “inside admission” i.e. the steam enters at the centre in this case into the annulus formed by the valve body.

The more common valve uses a solid body but therefore needs two exhaust outlets one above & one below. I have made a number of these types with complete success; however the piston and liner need to be made accurately as regards fit. I use plain bobbins with no rings, just some “water grooves”

Jack

It is usual practice to use “inside admission” i.e. the steam enters at the centre in this case into the annulus formed by the valve body.

The more common valve uses a solid body but therefore needs two exhaust outlets one above & one below. I have made a number of these types with complete success; however the piston and liner need to be made accurately as regards fit. I use plain bobbins with no rings, just some “water grooves”

Jack

- fredrosse

- Full Steam Ahead

- Posts: 1906

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Steam engine from the North Caucasus

Watertube boilers can be made with no welding, by use of tubes rolled into the larger drums. Large drum ends can be closed with a steel plate and gasket, held with strength by stay-bolts. These designs are reliable. You need a tube bending tool that can be made with your machine tools, to bend the watertubes with necessary dimensions. Rolling tubes into the boiler drums can also be accomplished with purchase of a tube rolling tool, although you also have the capability of making this tool without too much work.

-

Freezerrr12

- Warming the Engine

- Posts: 96

- Joined: Tue Aug 25, 2020 6:36 pm

- Boat Name: Anastasia

Re: Steam engine from the North Caucasus

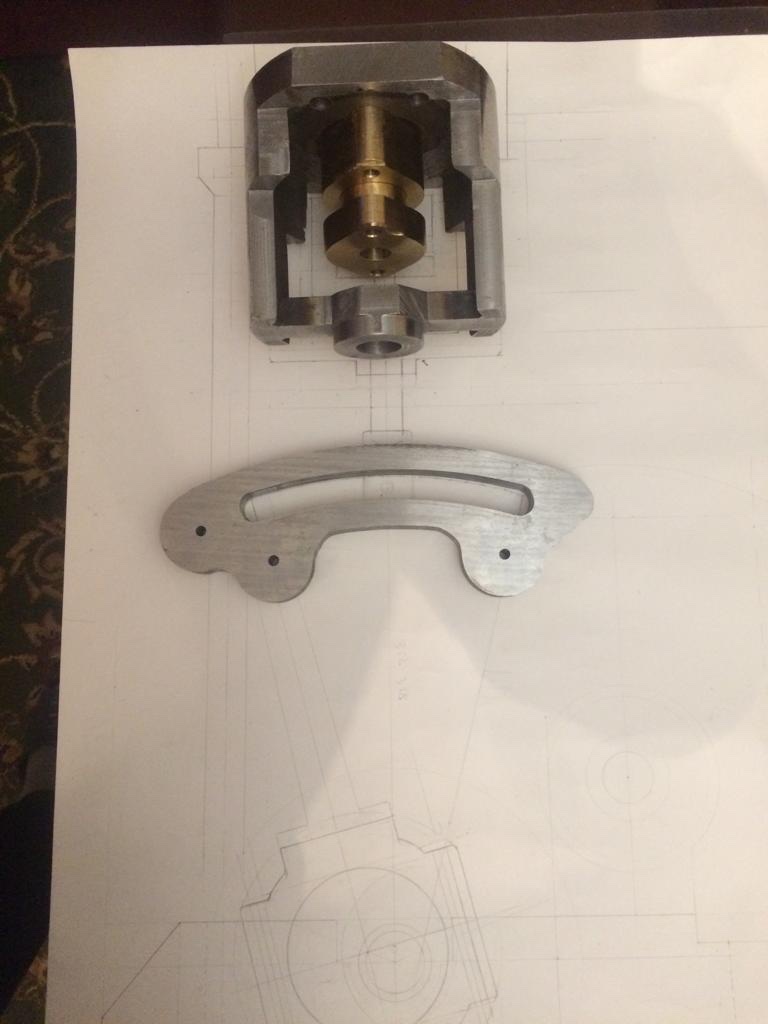

Dear DetroiTug, Tahoe Steam, Steamboatjack and FredRosse, I thank you and all the other contributors for recommending me. I have been carefully studying this entire forum and found that this is a guide to making a dream come true, and not just a chat for steamboat enthusiasts. For me, your advice is of great practical value. As I already mentioned, in Russia I know of two enthusiasts who built steam boats. But these boats are very modest compared to those that I saw on this forum. I bought inexpensively 60 meters of steel pipes with a diameter of 25 mm., Wall thickness-3 mm. These are very heavy pipes, but they were not expensive at all. Now I am inclined to design a steam boiler of the Yarrow system, which I think can be made with minimal bends in the water pipes. A steam drum (pipe) with a diameter of 14 inches, with a wall thickness of 14-15 mm, can be bought in the region where I live. I have such a pipe in mind. Therefore, I again turn to forum enthusiasts with the question: how best to attach such thick tubes to a steam drum? Do you need welding for this? Is it possible to expand tubing in a steam drum to withstand 220-250 psi? Does anyone have such experience? If I do not find information on how to make such a boiler in a home workshop, then I will have to resort to making a steam boiler of a design similar to the George Whitney boiler. But in the latter case, it will take me much longer. Thanks again for your feedback. I am attaching a photo of my next milling lesson. See you.

- Attachments

-

- PHOTO-2020-09-16-23-24-30.jpg (100.63 KiB) Viewed 331055 times

-

- PHOTO-2020-09-16-23-24-30.jpg (94.12 KiB) Viewed 331055 times

-

- PHOTO-2020-09-16-23-24-30.jpg (165.27 KiB) Viewed 331055 times

- RNoe

- Full Steam Ahead

- Posts: 250

- Joined: Sun May 26, 2019 5:29 pm

- Boat Name: Cluaran

- Location: Northern Oregon, USA

Re: Steam engine from the North Caucasus

You are doing remarkable work!

And please remember that boiler materials (tubes, steam drums) need to be low carbon steel, to prevent cracking and welding failures.

RussN

And please remember that boiler materials (tubes, steam drums) need to be low carbon steel, to prevent cracking and welding failures.

RussN

-

Oilking

- Full Steam Ahead

- Posts: 186

- Joined: Sun Sep 02, 2012 2:39 pm

- Boat Name: No Boat Yet

- Location: Cathlamet, WA

Re: Steam engine from the North Caucasus

Steam Boat Association of Great Britain has a library of boiler designs, from small to quite large, that have passed muster with the "authorities" as I understand. https://steamboatassociation.co.uk/page-1145952

You will have to join to make use of the service.

Magnificent work you are doing. I enjoy seeing how the project progresses.

Dave

You will have to join to make use of the service.

Magnificent work you are doing. I enjoy seeing how the project progresses.

Dave

- dampfspieler

- Full Steam Ahead

- Posts: 254

- Joined: Wed Nov 18, 2009 6:59 am

- Boat Name: No Boat Yet

- Location: Neubrandenburg, Germany

- Contact:

Re: Steam engine from the North Caucasus

Hi,

the slot is to short. You have to lenghten it so the stone can moove free in "full ahead"- and "full astern"-position and to get the full stroke.

Here two pics of my little STUART Launch Twin. It has also as short eccentric rods like yours, which require a lot of room to move beyond the linkage. A little more length would have been desirable, but the machine runs very well in the intended direction of rotation.

--

Dietrich

the slot is to short. You have to lenghten it so the stone can moove free in "full ahead"- and "full astern"-position and to get the full stroke.

Here two pics of my little STUART Launch Twin. It has also as short eccentric rods like yours, which require a lot of room to move beyond the linkage. A little more length would have been desirable, but the machine runs very well in the intended direction of rotation.

--

Dietrich