steel cylinder?

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

steel cylinder?

Would a steel cylinder weldment w/ cast iron piston & rings be practical for a steam boat? I would find fabricating a 5"x6" uniflow cylinder from steel tubing & plate, normalizing and welding a more practical proposition than casting same. I seem to remember this sort of construction being used in the past, but I'm wondering if anyone has done this personally or knows someone who has....

- Bart

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

- artemis

- Full Steam Ahead

- Posts: 465

- Joined: Wed Nov 18, 2009 4:13 am

- Boat Name: Pond Skimmer

- Location: Portland, Oregon, USA

- Contact:

Re: steel cylinder?

Ray HasBrouck Engines http://groups.yahoo.com/group/HasBrouckEngines/ has a lot of experience and many examples of various materials others used in creating his engines.barts wrote:Would a steel cylinder weldment w/ cast iron piston & rings be practical for a steam boat? I would find fabricating a 5"x6" uniflow cylinder from steel tubing & plate, normalizing and welding a more practical proposition than casting same. I seem to remember this sort of construction being used in the past, but I'm wondering if anyone has done this personally or knows someone who has....

- Bart

- fredrosse

- Full Steam Ahead

- Posts: 1906

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: steel cylinder?

Some steels are difficult to get a good cylinder finish, and generally perform worse than iron cylinder liners. I have found that the typical pipe steel or tubing steel (such as ordinary A178 boiler tubing) is not too good for a steam cylinder.

You could consider machining your assembly and using a diesel engine liner, pressed into your weldment. Cylinder liners matching your size requirements show up all the time on e-bay, with low prices. Be sure to stress relieve your weldment before machining, or else you will have a hard time getting reasonable machining tolorances. Stress relieving vendors are everywhere, and the cost is nominally low.

The attached picture is a liner currently on e-bay that probably could be adapted to your needs, although it is smaller than the one you plan. However the right size liner will show up fairly quickly if you can accept a bore that may be a little more or less than you originally planned for..

You could consider machining your assembly and using a diesel engine liner, pressed into your weldment. Cylinder liners matching your size requirements show up all the time on e-bay, with low prices. Be sure to stress relieve your weldment before machining, or else you will have a hard time getting reasonable machining tolorances. Stress relieving vendors are everywhere, and the cost is nominally low.

The attached picture is a liner currently on e-bay that probably could be adapted to your needs, although it is smaller than the one you plan. However the right size liner will show up fairly quickly if you can accept a bore that may be a little more or less than you originally planned for..

- Attachments

-

- About 4 inch bore iron liner

- CYL LINER.jpg (26.86 KiB) Viewed 10961 times

- gondolier88

- Full Steam Ahead

- Posts: 290

- Joined: Fri Jun 18, 2010 8:54 pm

- Boat Name: No Boat Yet

Re: steel cylinder?

Hydraulic cylinder tubing would be suitable for recieving a good finish if steel was the way you wanted to go.

Greg

Greg

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

Re: steel cylinder?

I'll keep an eye out for larger 2 stroke diesel liners on EBay - thanks for the tip!

These folks have new "all-purpose" sleeves that would allow lining a weldment after both heat treat and machining: http://www.lasleeve.com/all-purpose-sleeves

I'm interested in building a large single cylinder uniflow engine that produces about 10 hp @ 350 rpm w/ 15% cut-off for a 34' boat. I'm assuming a BMEP of about 55 psi given 250 psi boiler pressure; this seems about right acording to Kent's Mechanical Engineer's Handbook circa 1937. Some features I'm considering:

* roller crosshead

* needle bearing wrist pin, roller bearings for big end

* built-up crank

* poppet valves

* shifting cam for cut-off changes, reverse.

* steam eductor to produce vacuum in condenser for starting, reversing

- Bart

These folks have new "all-purpose" sleeves that would allow lining a weldment after both heat treat and machining: http://www.lasleeve.com/all-purpose-sleeves

I'm interested in building a large single cylinder uniflow engine that produces about 10 hp @ 350 rpm w/ 15% cut-off for a 34' boat. I'm assuming a BMEP of about 55 psi given 250 psi boiler pressure; this seems about right acording to Kent's Mechanical Engineer's Handbook circa 1937. Some features I'm considering:

* roller crosshead

* needle bearing wrist pin, roller bearings for big end

* built-up crank

* poppet valves

* shifting cam for cut-off changes, reverse.

* steam eductor to produce vacuum in condenser for starting, reversing

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

- artemis

- Full Steam Ahead

- Posts: 465

- Joined: Wed Nov 18, 2009 4:13 am

- Boat Name: Pond Skimmer

- Location: Portland, Oregon, USA

- Contact:

Re: steel cylinder?

The engine in David Ayers' Elpenor is 3.5" bore and 5" stroke. Poppet valve, cam activated with an interesting and mechanically sound valve action. It's in the Mar/Apr 2008 issue of Steamboating Magazine, Vol XII, No. 2 - you should have a copy in your collection.

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: steel cylinder?

Hi Bart,

The design considerations you've outlined are coincidentally similar to the design a buddy of mine is working on. He made some of the parts here in my shop.

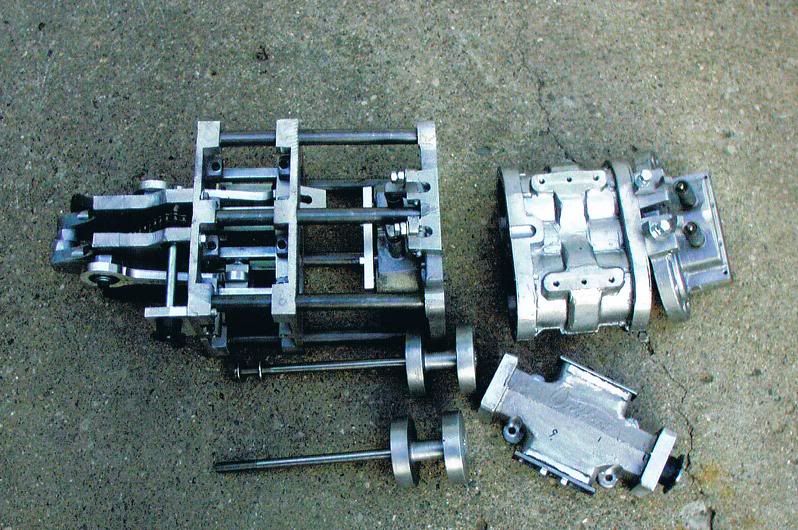

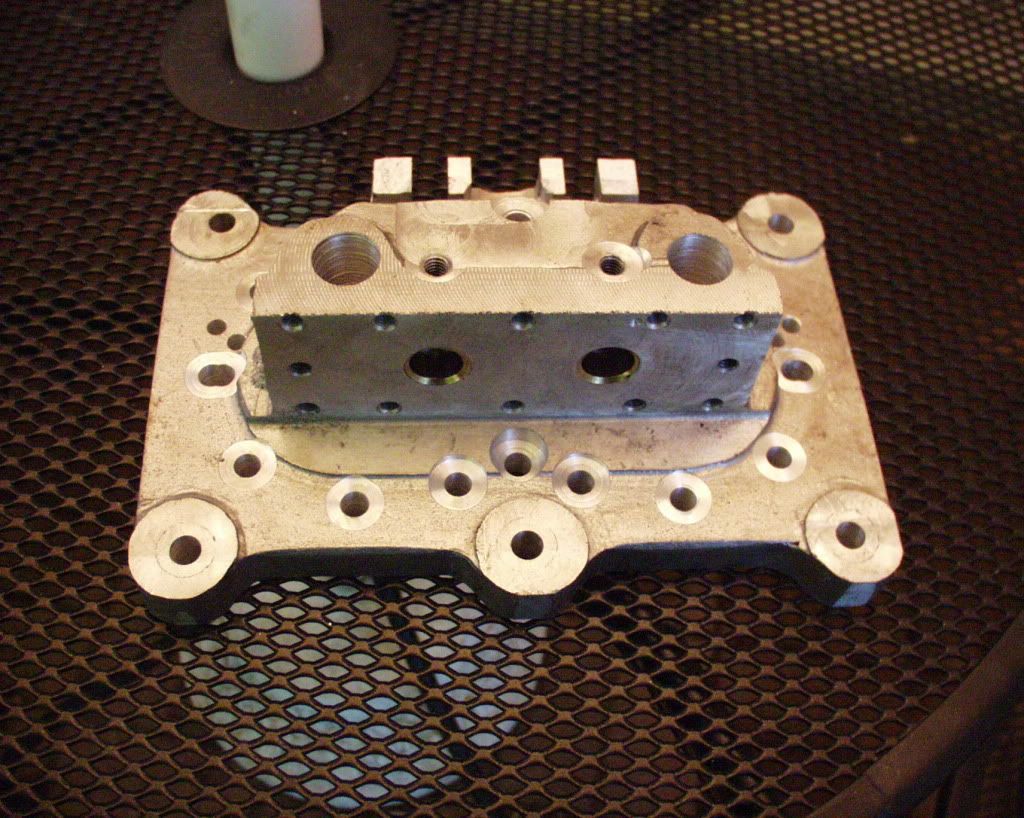

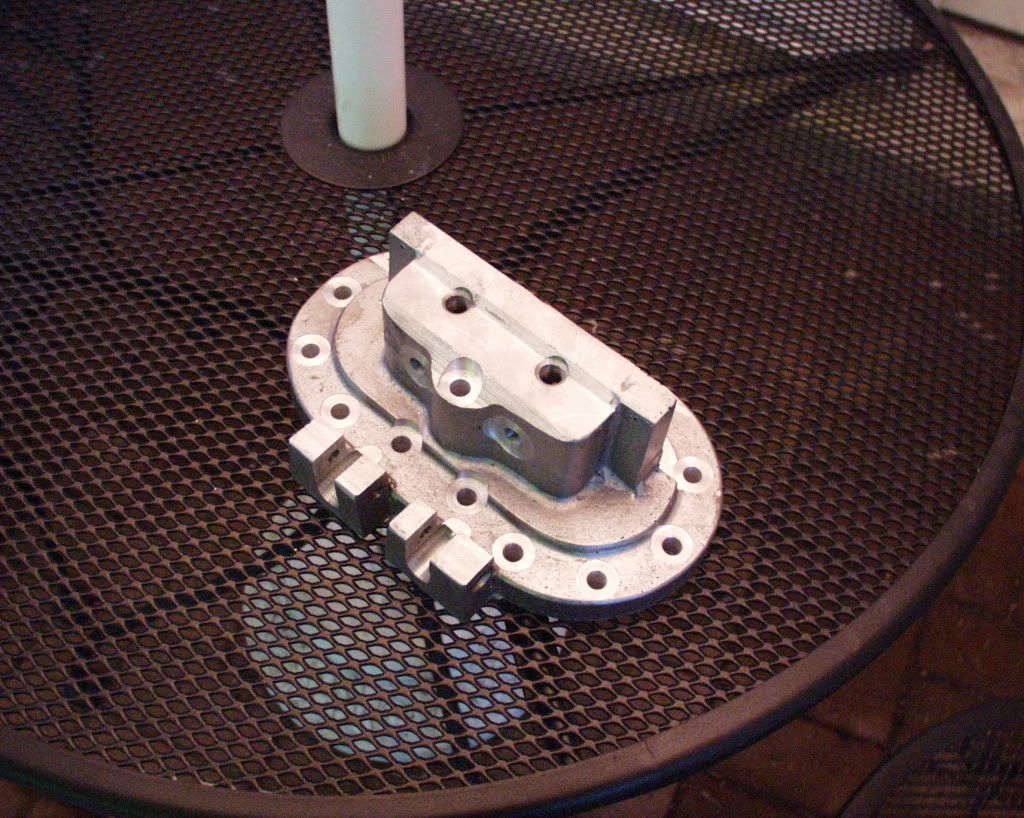

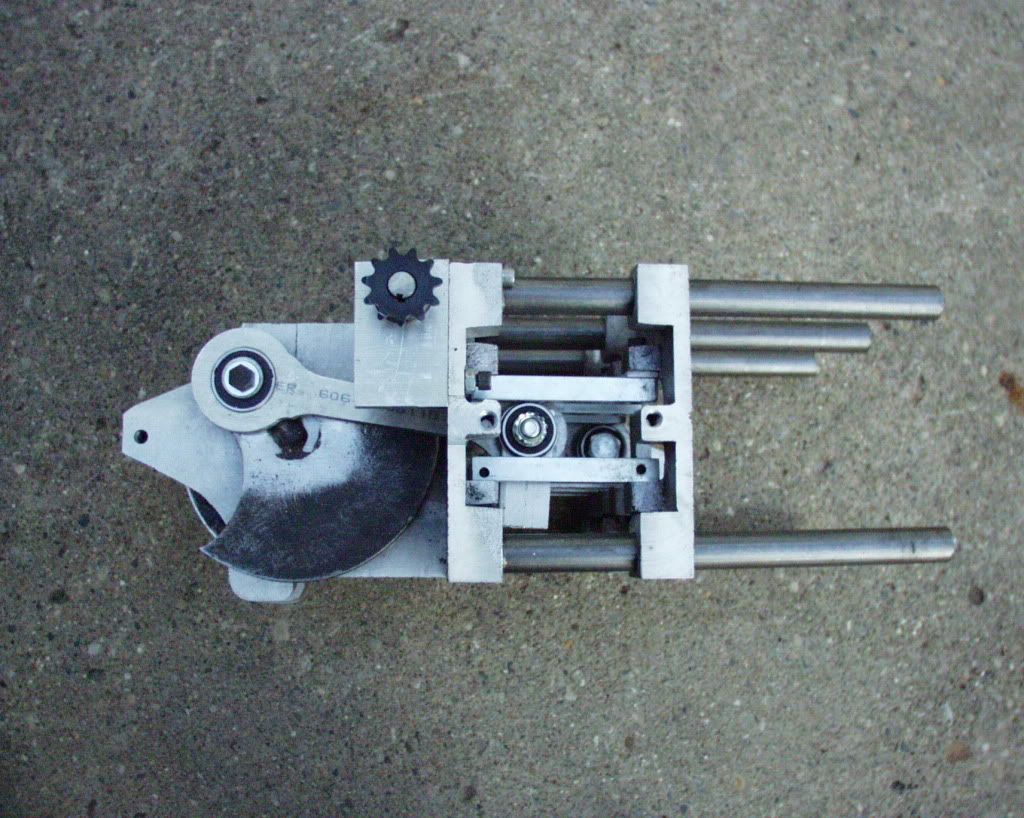

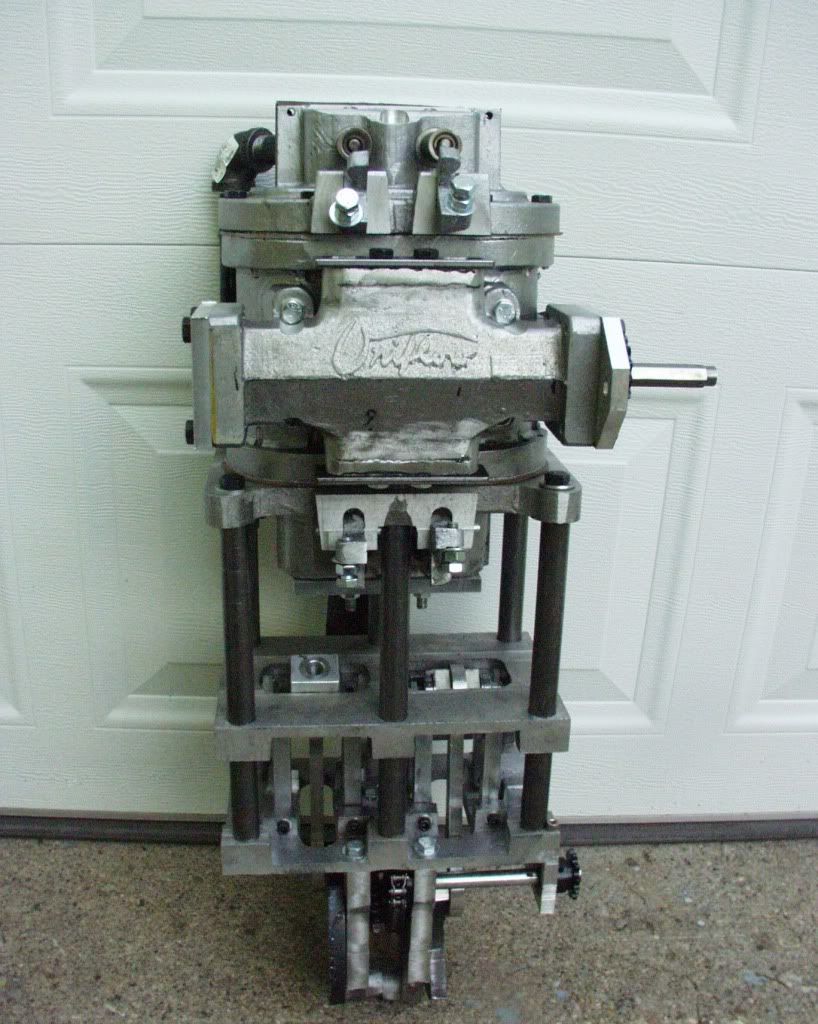

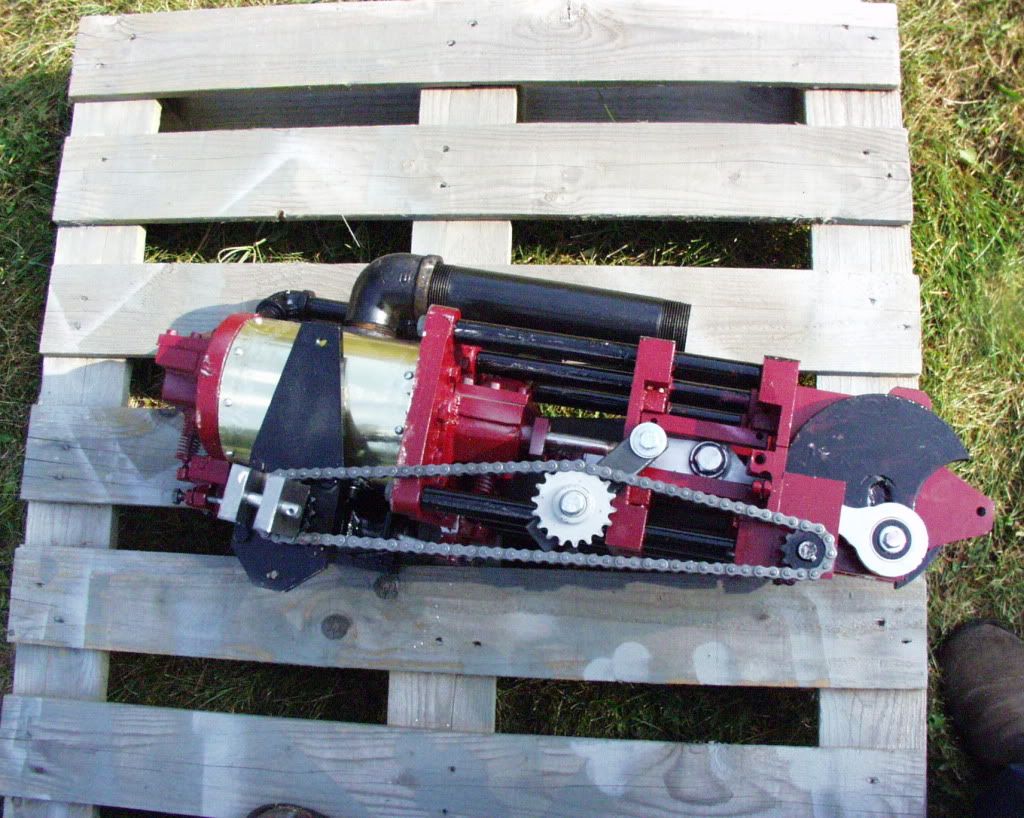

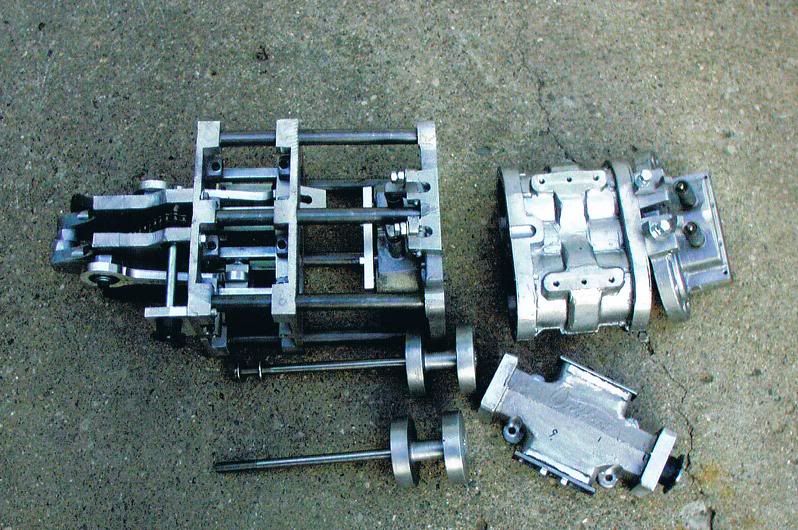

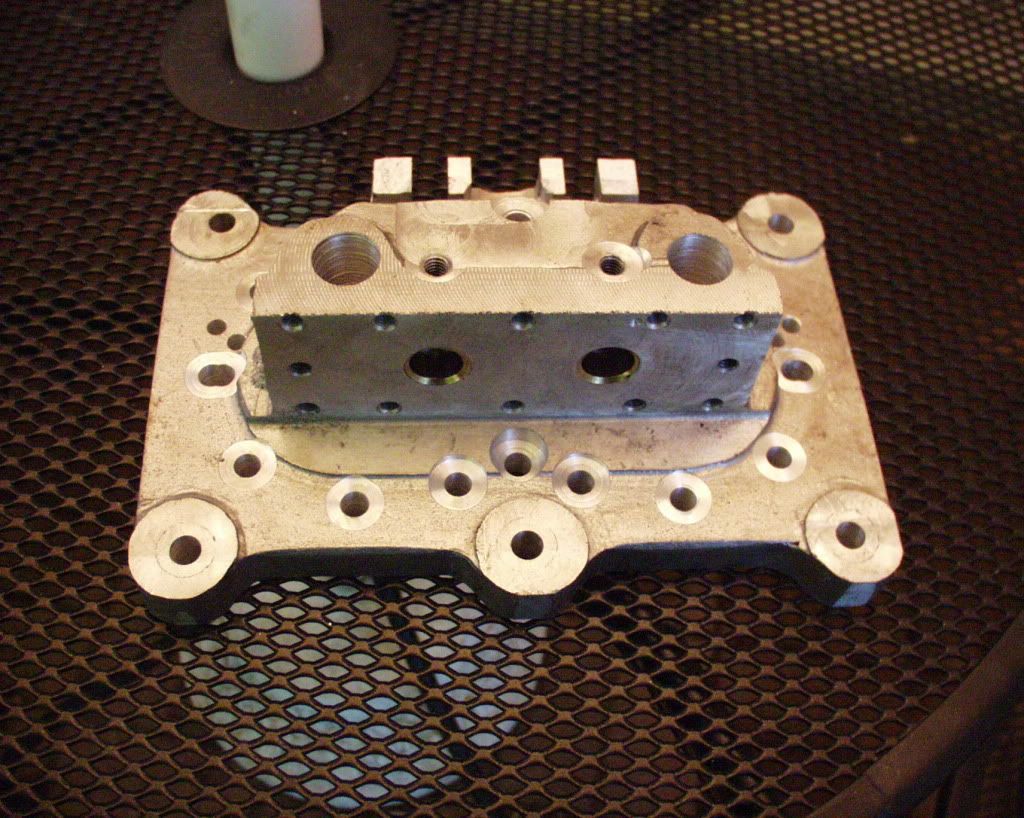

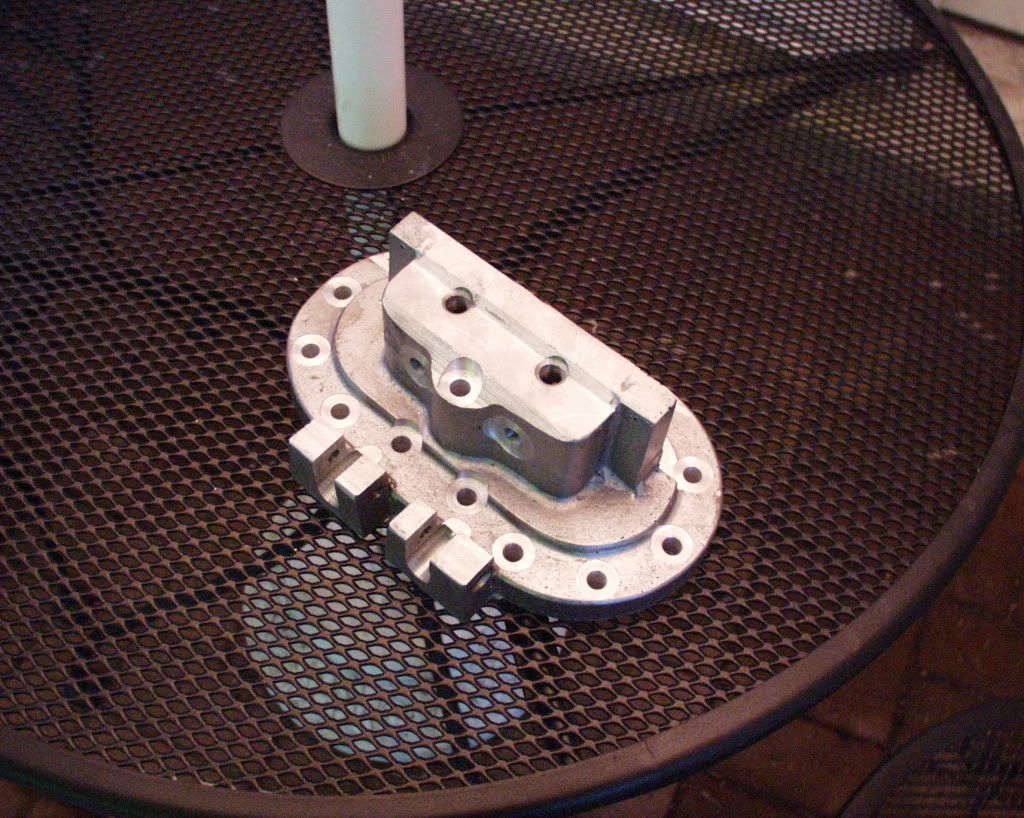

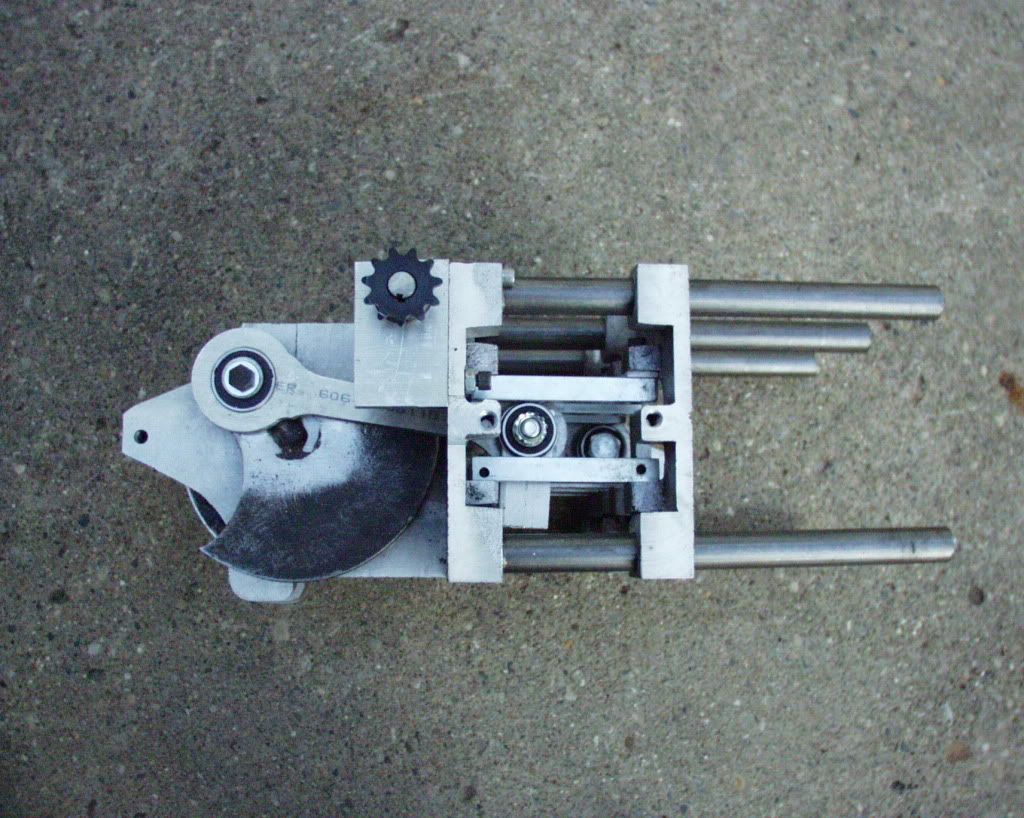

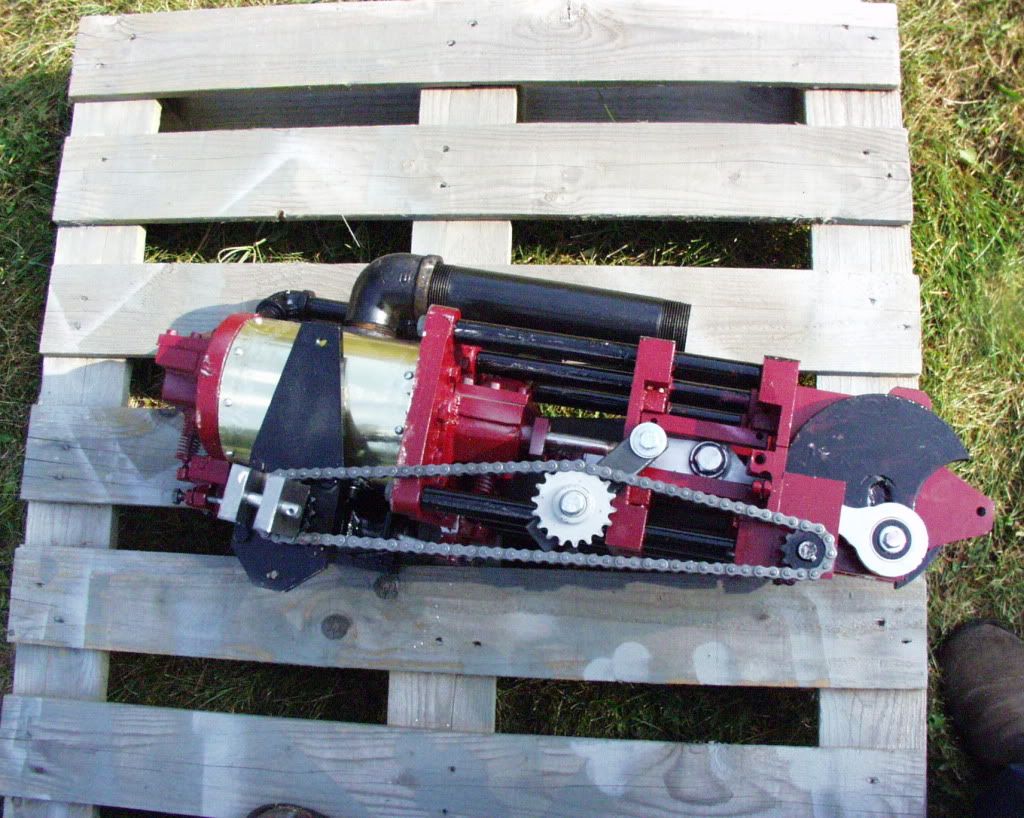

This automobile twin Uniflow is 3+3X4. It is all aluminum construction of his own design. The sleeves are 303 stainless tube. The rings are ampco bronze. The valves are Briggs and Stratton. It uses the sliding camshaft that we are going to manufacture here in a 4th axis CNC setup. He has one of these in a boat that he's been using for years, and is holding up well, same design different materials. This is the first with stainless sleeves/ bronze rings. He intends to sell these casting sets as a kit. This is just a prototype, the kits will feature many iron castings instead of the Al. He has ran the prototype on steam for several hours and it appears to be holding up just fine and maintaining compression.

There will be a marine version of this engine as well with a suitable mounting base.

I just got off the phone with him and he said it was OK to post these pics.

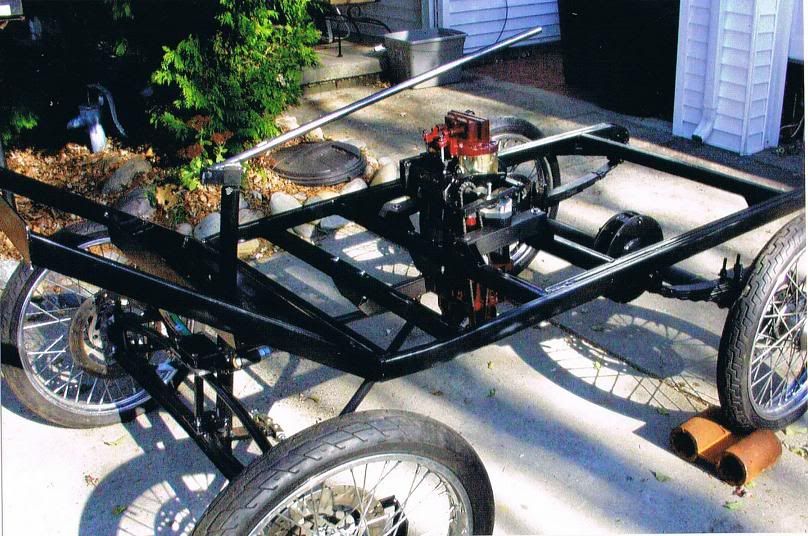

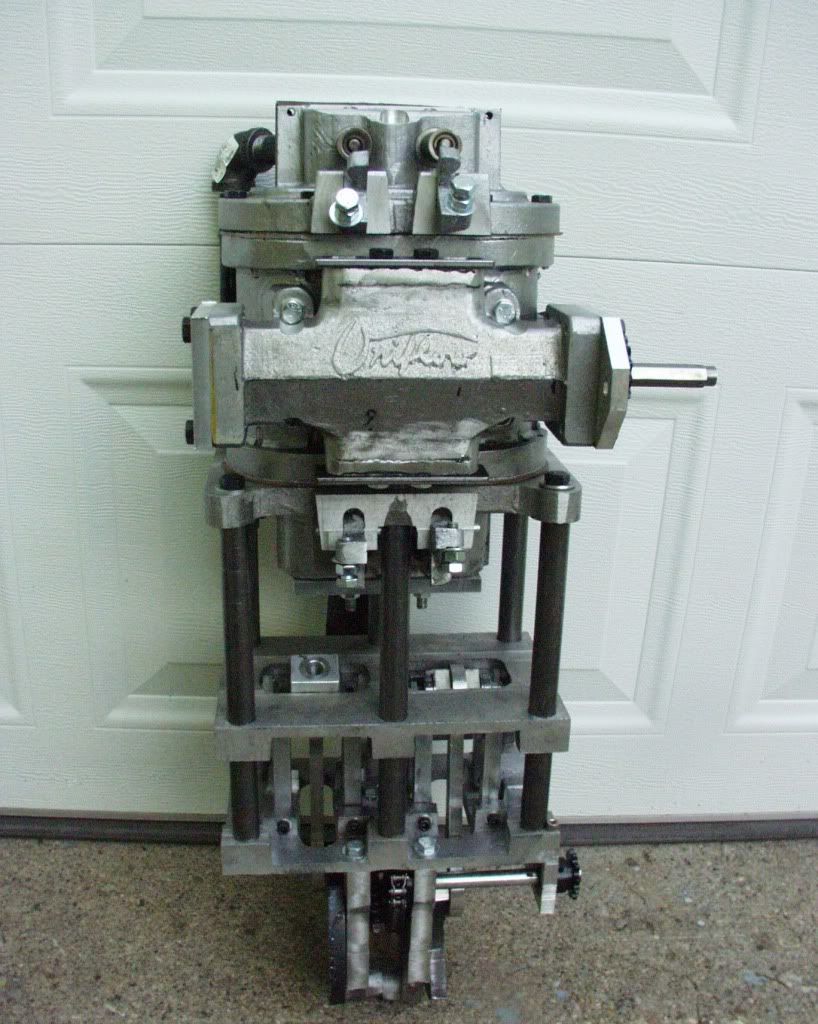

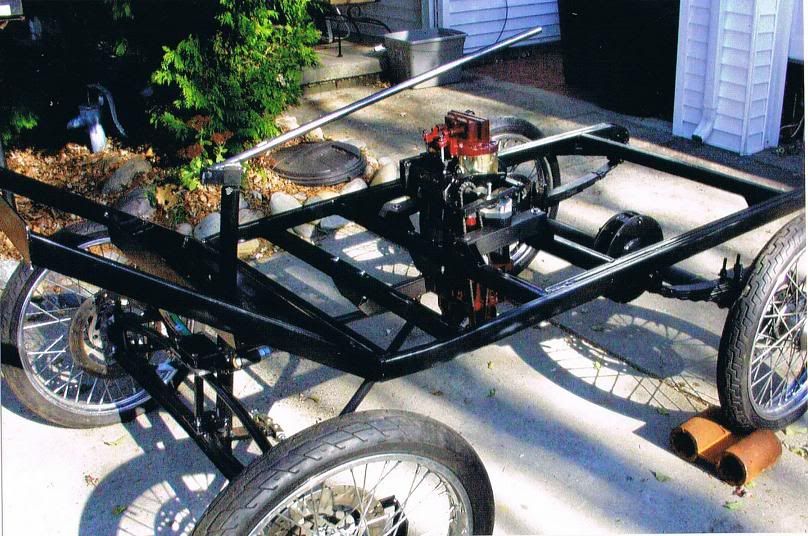

Here it is installed in the chassis, since this pic was taken the boiler has been built and the car has been driven. He used a Clayton boiler and now is moving on to an Ofeldt design. Another buddy, Tony Grzyb who runs the tug with me sometimes, uses an Ofeldt in his Steamcar with great results.

-Ron

The design considerations you've outlined are coincidentally similar to the design a buddy of mine is working on. He made some of the parts here in my shop.

This automobile twin Uniflow is 3+3X4. It is all aluminum construction of his own design. The sleeves are 303 stainless tube. The rings are ampco bronze. The valves are Briggs and Stratton. It uses the sliding camshaft that we are going to manufacture here in a 4th axis CNC setup. He has one of these in a boat that he's been using for years, and is holding up well, same design different materials. This is the first with stainless sleeves/ bronze rings. He intends to sell these casting sets as a kit. This is just a prototype, the kits will feature many iron castings instead of the Al. He has ran the prototype on steam for several hours and it appears to be holding up just fine and maintaining compression.

There will be a marine version of this engine as well with a suitable mounting base.

I just got off the phone with him and he said it was OK to post these pics.

Here it is installed in the chassis, since this pic was taken the boiler has been built and the car has been driven. He used a Clayton boiler and now is moving on to an Ofeldt design. Another buddy, Tony Grzyb who runs the tug with me sometimes, uses an Ofeldt in his Steamcar with great results.

-Ron

Re: steel cylinder?

Ron,

Is your friend with the twin uniflow accepting orders yet? That engine looks fantastic and I might like to be the first in line for a set of castings. I have been noodling around with a uniflow design of exactly those dimensions for some time, but have not taken the plunge into construction. I'd love to start with a proven cylinder and valve design.

Cheers,

Scott

Is your friend with the twin uniflow accepting orders yet? That engine looks fantastic and I might like to be the first in line for a set of castings. I have been noodling around with a uniflow design of exactly those dimensions for some time, but have not taken the plunge into construction. I'd love to start with a proven cylinder and valve design.

Cheers,

Scott

-

steamboatjack

- Full Steam Ahead

- Posts: 283

- Joined: Fri Nov 20, 2009 8:02 am

- Boat Name: grayling

- Location: Cumbria U.K.

Re: steel cylinder?

Regarding Uniflow, great on boats I would love to build one myself, as regards cars I'm no expert but I know Abner Doble decided that the uniflow was not ideal presumably due to the well know starting compressing problem.

Regards Jack

Regards Jack

- barts

- Full Steam Ahead

- Posts: 1070

- Joined: Wed Nov 18, 2009 6:08 am

- Boat Name: Otter, Rainbow

- Location: Lopez Island, WA and sometimes Menlo Park, CA

- Contact:

Re: steel cylinder?

Low clearance uniflow engines work quite well so long as adequate vacuum is available - even when the engine is just started. I plan to attack this by using a steam eductor to pull a vacuum in the condenser before admitting steam to the engine; once the engine was warm and running smoothly it will be turned off as the engine driven pump will provide needed scavenging. The alternative approach is to add either add additional exhaust poppet valves to be used in low vacuum conditions or to fit valves connected to additional clearance volume to prevent excessive compression under the same conditions.

- Bart

- Bart

-------

Bart Smaalders http://smaalders.net/barts Lopez Island, WA

Bart Smaalders http://smaalders.net/barts Lopez Island, WA