Excellent - thanks for all the info, Fred. Lots to reply to here!

I'd thought about modeling release; I've not done that yet in my calculations and need to add that in. [I use a small python program to do all the calculations; it makes varying parameters much easier]. I note fairly high exhaust back pressure (10 PSIA) in the two cylinder marine engine; most of the boats I'm seeing are running about 2 PSIA (26 inches hg), which definitely makes a difference when looking to use shorter cut-offs and when calculating BMEP.

The poppet valve is simple and clever; I assume this design is for a single acting engine?

The 23 CID single acting engine is relatively simple. I'm somewhat hesitant to put a spring in the high temperature steam, though. The use of clamps to retain the valve assemblies is worth remembering. There seems to be limited space for sealing the high pressure valve stem; how was this done?

I've been mulling over sealing the various bolted together surfaces. In the exhaust portion of the engine viton o-rings will work nicely; I need to use o-rings there since the clamping force is orthogonal to the sealing surfaces. In the cylinder heads, I'm inclined to machine a small indentation and use high temperature automotive RTV sealant; this works fine at 600F. The cylinder end components are indeed aligned with alignment recesses on both sides of the cylinder head and the underside of the steam chest cap.

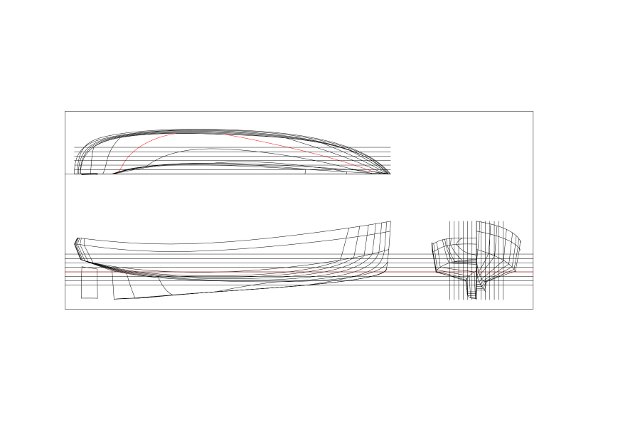

My brother designs boats (along with other things); his website is

http://smaalders.net/yacht_design/. He's doing the design for the hull; here's an initial proposed sketch of the lines, including a box keel to facilitate beaching (nice to be able to do in the San Juans):

- Sea Lion draft lines_Dec 2012.jpg (18.67 KiB) Viewed 10431 times

. I've got copies of Skene's Elements of Yacht Design and David Gerr's Propeller Handbook here, so running the basic numbers is not difficult. We're going to emphasize efficient performance at 6 - 7 knots; burning two or three times the fuel to go 8 or 9 is fun at a steamboat meet, but for longer distances quite impractical. I want to take this boat all over the Northwest via water, so living aboard in comfort is an important part of the design.

- Bart