Page 2 of 5

Re: water pickup

Posted: Thu Mar 19, 2015 3:44 am

by cyberbadger

Lopez Mike wrote:Also (personal gripe) they are noisy.

What? When an injector picks up it sings.

That's why I like this hobby. It's what I got out Bill Durham's Book: you can do it many many different ways. Make it, buy it, a mix. Go for historical, non traditional, trampy, hybrid. Take decades to plan it, or put it together in a few years. It's your boat, and if it floats, moves under steam, and you respect and understand the dangers of steam - It's a successful steamboat.

Mike/Ron: Can you give a link to the Hypro pump model? Also pictures any pictures/links of a conversion.

lighthouse needs as many potential feedwater options as he can get, and then he can choose what he's going to do.

-CB

Re: water pickup

Posted: Thu Mar 19, 2015 4:16 am

by Lopez Mike

I use a Hypro 5300. I have it driven directly off of my Strath Warrego 5 h.p. single running at engine speed. It keeps ahead of the engine just fine. I have it mounted with the output pointing up so that any air can get out.

It just runs. The only time I have had any feedwater probelms has been due to the filter slowly getting plugged up with fine particles. The symptom was the hot well over flowing and the sight glass dropping a bit and, when I bothered to look at things, the little outboard gas line squeeze pump between the hot well and the pump input was sucked flat. Duh!

Reached in the hotwell. Wiped of enough of the grunge for things to start flowing and dealt with the problem properly when I get home.

Re: water pickup

Posted: Thu Mar 19, 2015 1:28 pm

by DetroiTug

I think mine is a 5300 too? It was one step up from the smallest. Any of them will work and they are very common, many sources on the web.

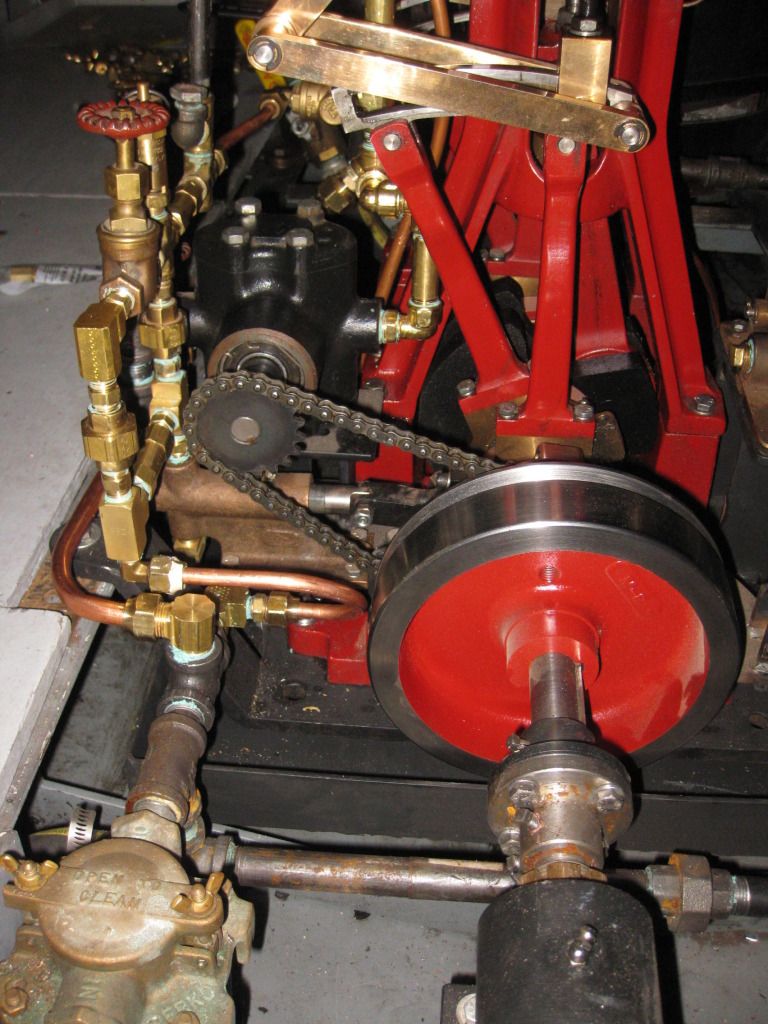

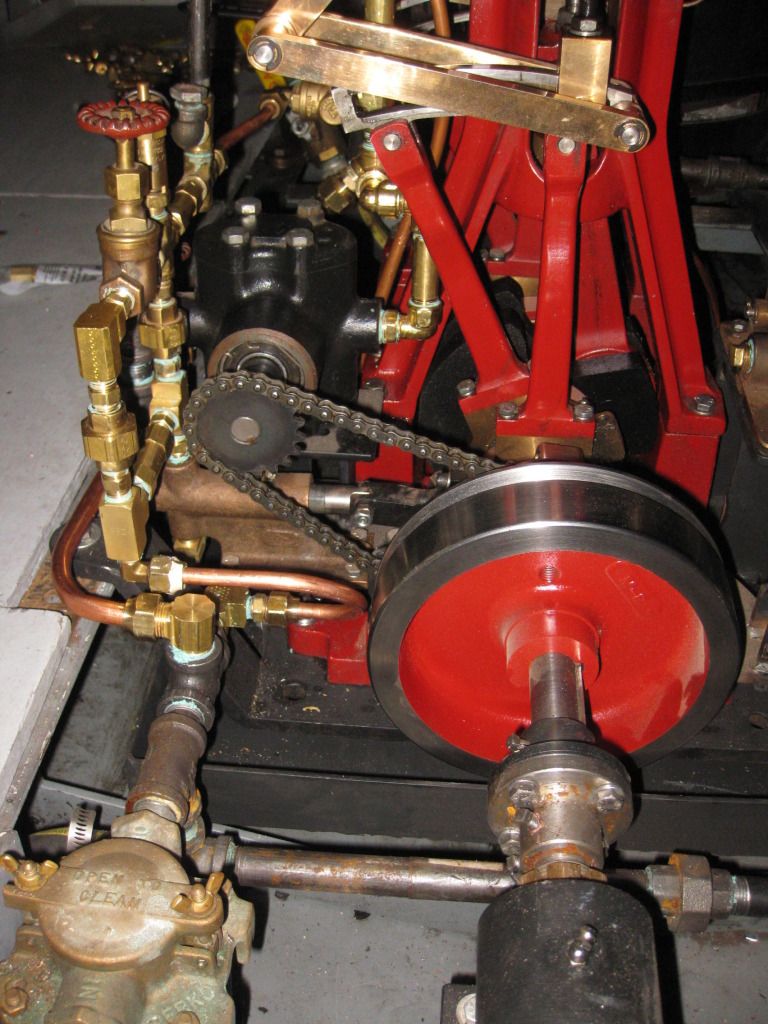

Here is my install, I retained the old piston pump and mounted the Hypro atop to have two engine driven pumps. I've yet to be in a situation where I've had to use the handpump. The plumbing of these two propelled me to first-name status with the local hardware though.

Notice in the pics, I have mine running at 2:1 ratio. It's too much, even at the pressures I'm running (40-80 psi) and all the water that slobbers through (saturated steam) the engine, the pump only needs to run about 1/3rd the time. And due to the higher velocity of feedwater, it requires much more economizer or simply cools the economizer completely down and it's like not having one. We typically play the bypass and try to get it just keeping up - that is where the plant runs the best. The old adage on boiler firing is "Little and often" and it means fuel and water.

Of course, this is how we "used" to do it before the addition of the Southworth steam pump which is now my primary feedwater pump. The pump which takes it's steam from the middle trycock keeps the boiler at that level all of the time. So it's just add wood and watch the glass for the engineer.

-Ron

Re: water pickup

Posted: Thu Mar 19, 2015 2:45 pm

by Lopez Mike

Sheesh! That plumbing looks like the inside of a chinaman's mind trying to say L.

I have a small Paul Bresch duplex that is mostly machined. Even though I don't need it, the idea of another dingbat chugging away to amaze passengers sort of appeals to me.

And I like that idea of feeding it from the try cock. Seems to work reliably? No serious problem with hydraulic lock when cycling on and off?

Re: water pickup

Posted: Thu Mar 19, 2015 4:21 pm

by johngriffiths

Play it safe, use two separate supplies to the feed systems because a leak or problem in one will effect both if fed from a single 'sea cock'. Neither pumps nor injectors work if the feed is blocked or is leaking air. Also put sea cocks on all holes in the hull, including wastes from sinks and the like, boats have had big problems when a plastic pipe has come away. The schedules used by boat inspectors for the UK canals and rivers specify 'sea cocks' be fitted and functional.

John G

Re: water pickup

Posted: Thu Mar 19, 2015 5:16 pm

by DetroiTug

JohnG,

Sage advice indeed. I only have one, but I use marine rated hose with steel braid - it's more of a flexible pipe than it is a hose. I've never had any issue with using just one pickup. Most old inboard boats only have one and the pickup becoming clogged on them is a very rare occurrence. On the tug, the pickup and screen is just ahead of the prop, so a fast reverse wash over it would flush away whatever is covering it. So far, never had that issue. Seacocks, every thru-hull should have one. Again though, the old inboard boats which there have been millions, very few that I have seen had seacocks on underwater thru-hulls. Just a fitting to a marine rated hose. And yes, some sunk, but it was very rare.

Mike,

The only issue I had with the steampump is the Orings that came with them were too soft and just disintegrated. Went to a 70 durometer neoprene O-ring and mine has been running reliably for 2 seasons. They need an oiler though for the O-rings.

Yes, keeps the water right at the middle trycock.

-Ron

Re: water pickup

Posted: Thu Mar 19, 2015 9:33 pm

by Lopez Mike

No O-rings in the Bresch design. Rings on the steam side and cups on the water end. I have yet to make the water side valves. Looks like a fussy job at best.

Re: water pickup

Posted: Thu Mar 19, 2015 10:16 pm

by cyberbadger

Thanks Mike and Ron!

-CB

Re: water pickup

Posted: Fri Mar 20, 2015 12:08 am

by steamdon-jr

I have never had a problemon Adelaide or Phoebe Snow with one feed, also have the hypro, a 3/8" Penberthy that works flawlessly and a hand pump...in Adelaide we had a electric pimp to fill the hotwell.....we had it plumbed as a backup boiler feed as well and at one time we used it religiously for about 12 days as our boiler feed on one charge off a 12 volt dep cycle battery.

Really like the setup we have now...only electronics will be lights and power for ipad to use my charting program along with GPS. Just got a 12 quart double boiler that I am going to plumb up to steam corn and clams or make soups & chili.

Re: water pickup

Posted: Fri Mar 20, 2015 12:35 am

by lighthousekeeper

thanks for all the great advice, I'm leaning toward the hypro pump. For give me if this is a stupid question my boiler safety valve is set at 95 psi now how much psi would the hypro pump need to put water in the boiler? and second stupid question haha is the pump running all the time? being on a v belt ? and just one more question just roughly how much water do you need to pump in a average size boiler per hour? thanks!