Triple Expansion Engine - Elliott Bay

- marinesteam

- Full Steam Ahead

- Posts: 313

- Joined: Thu Nov 19, 2009 2:51 am

- Boat Name: Idris

- Location: Colorado USA

Re: Triple Expansion Engine - Elliott Bay

Hello,

I would like know what type of steel you are using for the columns and what finish (if any) has been or is going to be applied? Also, do you have any concerns about corrosion if they will be left bare?

The engine looks likes it's coming along well. I know there is quite a few more parts in the EB triple than in the York that I am building, I bet it's quite a thrill to see it coming together. I can't wait until I progress that far.

Ken

I would like know what type of steel you are using for the columns and what finish (if any) has been or is going to be applied? Also, do you have any concerns about corrosion if they will be left bare?

The engine looks likes it's coming along well. I know there is quite a few more parts in the EB triple than in the York that I am building, I bet it's quite a thrill to see it coming together. I can't wait until I progress that far.

Ken

-

steamboatjack

- Full Steam Ahead

- Posts: 283

- Joined: Fri Nov 20, 2009 8:02 am

- Boat Name: grayling

- Location: Cumbria U.K.

Re: Triple Expansion Engine - Elliott Bay

Ken,

Hi the columns are of stainless steel, 303 is best as it’s free cutting. I also use only stainless nuts as it’s not worth doing otherwise, the only exception being if higher tensile fasteners are required, A2 stainless is ok but not as strong as some people think, also its most important to use a lubricant on the threads.

Rust I am afraid is a pain for all steam boaters and there is no easy answer, I kept my boat Grayling in a boathouse on Windermere for a number of years with no rust at all due to the fairly slow rate of temperature change, on the trailer its another matter, I really need to win the lotto to buy a boat house in the lakes. Any pics of the York compound available?

Hi the columns are of stainless steel, 303 is best as it’s free cutting. I also use only stainless nuts as it’s not worth doing otherwise, the only exception being if higher tensile fasteners are required, A2 stainless is ok but not as strong as some people think, also its most important to use a lubricant on the threads.

Rust I am afraid is a pain for all steam boaters and there is no easy answer, I kept my boat Grayling in a boathouse on Windermere for a number of years with no rust at all due to the fairly slow rate of temperature change, on the trailer its another matter, I really need to win the lotto to buy a boat house in the lakes. Any pics of the York compound available?

- marinesteam

- Full Steam Ahead

- Posts: 313

- Joined: Thu Nov 19, 2009 2:51 am

- Boat Name: Idris

- Location: Colorado USA

Re: Triple Expansion Engine - Elliott Bay

Hello,

I currently do not have any pics of the York engine. I have been working on some other projects while working up the nerve to start machining the castings of the York. I have however begun to work on some of the parts of the engine. I am fettling the castings prior to machining. The intent is to finish all of the bronze bright and figured that the best approach would be to do most of the major smoothing of the castings to the point of being ready for polishing, then machining the pieces and completing polishing afterward. The idea is that I am sure that I will ding a casting during machining and that can be removed easily without spoiling the finish and I can still feel like I am working on the engine in the mean time. I am also intending to hone my machining skills on the bar stock parts before tackling the machining of the castings.

I hadn't considered stainless for the steel components. I am still deciding what finish would look good with the bronze. Currently, I am leaning toward polished steel for the front columns (the York has cast iron rear columns & guides) so stainless has some merit. I will probably use a dark brown parkerized finish for the remaining steel components.

I do plan on posting pics of the York engine as I make progress.

Thanks

Ken

I currently do not have any pics of the York engine. I have been working on some other projects while working up the nerve to start machining the castings of the York. I have however begun to work on some of the parts of the engine. I am fettling the castings prior to machining. The intent is to finish all of the bronze bright and figured that the best approach would be to do most of the major smoothing of the castings to the point of being ready for polishing, then machining the pieces and completing polishing afterward. The idea is that I am sure that I will ding a casting during machining and that can be removed easily without spoiling the finish and I can still feel like I am working on the engine in the mean time. I am also intending to hone my machining skills on the bar stock parts before tackling the machining of the castings.

I hadn't considered stainless for the steel components. I am still deciding what finish would look good with the bronze. Currently, I am leaning toward polished steel for the front columns (the York has cast iron rear columns & guides) so stainless has some merit. I will probably use a dark brown parkerized finish for the remaining steel components.

I do plan on posting pics of the York engine as I make progress.

Thanks

Ken

- artemis

- Full Steam Ahead

- Posts: 465

- Joined: Wed Nov 18, 2009 4:13 am

- Boat Name: Pond Skimmer

- Location: Portland, Oregon, USA

- Contact:

Re: Triple Expansion Engine - Elliott Bay

Edward wrote:

Nothing wrong with the figures, but I would caution our cousins across the pond to remember than American engines tend to be "long legged" (ration of crank dia:conn rod length). This comes from a desire to reduce "angularity" and thus improve performance/valve events/economy. To turn these long legged engines (the York compound is another good example) over above 400rpm is to is to throw a lot of metal around at rather high speeds.

Ken Hall of Vancouver, BC - who built the first practical Elliott Bay Triple (Peter Cowie visited/corresponded with him a great deal) has his installed in a 23.5' Elliott Bay Hull. His boiler, a 49sq.ft. Ofeldt, provides steam to the engine at 185psi to produce approx. 8HP while turning a 20" x 34" propeller at 375rpm. I have ridden in Oesa many times since she was launched in 1997 - she always operates smoothly, quietly and reliably!

I hasten to add that Mr. Hall comes with excellent credentials being a retired LPE, steam, with a degree in Mech.Eng. steam from the U of BC and having designed and supervised the erection of many steam engines and boilers.

It ocurred to me that the estimated steam consumption figures for this triple might be of interest. As a general rule of thumb triples need a steam pressure of 150+psi; of course a lot depends on the ratios between the volumes of the cylinders and also the vacuum in the condenser.

The cylinder dimensions are 2 3/4"+ 4 3/8"+6 1/2" x 4".

Estimated steam consumption is as follows:

At 180psi , 500rpm=254 lbs per hour, 250rpm=127 lbs per hour.

At 200psi , 500rpm=275 lbs per hour, 250rpm=138 lbs per hour.

I hope these figures are of interest. If anyone can spot any flaws I'd be grateful to receive their views.

Nothing wrong with the figures, but I would caution our cousins across the pond to remember than American engines tend to be "long legged" (ration of crank dia:conn rod length). This comes from a desire to reduce "angularity" and thus improve performance/valve events/economy. To turn these long legged engines (the York compound is another good example) over above 400rpm is to is to throw a lot of metal around at rather high speeds.

Ken Hall of Vancouver, BC - who built the first practical Elliott Bay Triple (Peter Cowie visited/corresponded with him a great deal) has his installed in a 23.5' Elliott Bay Hull. His boiler, a 49sq.ft. Ofeldt, provides steam to the engine at 185psi to produce approx. 8HP while turning a 20" x 34" propeller at 375rpm. I have ridden in Oesa many times since she was launched in 1997 - she always operates smoothly, quietly and reliably!

I hasten to add that Mr. Hall comes with excellent credentials being a retired LPE, steam, with a degree in Mech.Eng. steam from the U of BC and having designed and supervised the erection of many steam engines and boilers.

-

Edward

- Full Steam Ahead

- Posts: 138

- Joined: Tue Nov 17, 2009 9:25 pm

- Boat Name: No Boat Yet

- Location: Ambleside , Cumbria , UK.

Re: Triple Expansion Engine - Elliott Bay

Dear Artemis,

Your comment on high RPM is quite understood . When I posted my estimates for steam consumption I just picked nice round figures rather than what I intended to run at .

For me a lot of the attraction of steam is that you can see what's happening , so for normal cruising 200-350 RPM is plenty....of course it would be nice occassionally to to see what she can do....

Simpson Strickland produced a small triple of very similar size for which they claimed an output of 35 HP at 750 RPM and 350 PSI . I suspect this was IHP rather than on a brake , and I'm not sure what the engines' life would be at these RPM ! I believe my crank shaft has been spun at 1200 RPM and didn't shake the lathe to bits but I don't think my boiler would be quite up to that !

The boiler I intend to use , should it pass its next test , is a vertical firetube with a waterleg and has a heating surface of just over 36 sq ft. When it was built it was tested and certified for a working pressure of 200 PSI .

Traditional wisdom says one should get about 5lbs per hour from each sq ft of heating surface in firetube boilers ; I hope to get a bit more than that as the firebox is quite large (2' diameter X 13" high) but even so I doubt that I would be able to sustain more than 350-400 RPM and I don't think the coupling between engine and shaft with a 20"x36" prop would like much more.

If anyone is interested I'll post fuller details of the boiler so people can work out the output for themselves and let me know by how much my estimates are wrong.

Thanks for your observation/comment

Edward

Your comment on high RPM is quite understood . When I posted my estimates for steam consumption I just picked nice round figures rather than what I intended to run at .

For me a lot of the attraction of steam is that you can see what's happening , so for normal cruising 200-350 RPM is plenty....of course it would be nice occassionally to to see what she can do....

Simpson Strickland produced a small triple of very similar size for which they claimed an output of 35 HP at 750 RPM and 350 PSI . I suspect this was IHP rather than on a brake , and I'm not sure what the engines' life would be at these RPM ! I believe my crank shaft has been spun at 1200 RPM and didn't shake the lathe to bits but I don't think my boiler would be quite up to that !

The boiler I intend to use , should it pass its next test , is a vertical firetube with a waterleg and has a heating surface of just over 36 sq ft. When it was built it was tested and certified for a working pressure of 200 PSI .

Traditional wisdom says one should get about 5lbs per hour from each sq ft of heating surface in firetube boilers ; I hope to get a bit more than that as the firebox is quite large (2' diameter X 13" high) but even so I doubt that I would be able to sustain more than 350-400 RPM and I don't think the coupling between engine and shaft with a 20"x36" prop would like much more.

If anyone is interested I'll post fuller details of the boiler so people can work out the output for themselves and let me know by how much my estimates are wrong.

Thanks for your observation/comment

Edward

- Maltelec

- Master of the Forum

- Posts: 269

- Joined: Sat Nov 14, 2009 7:01 pm

- Boat Name: No Boat Yet

- Location: Cumbria, UK

- Contact:

Re: Triple Expansion Engine - Elliott Bay

Here is another video of the Triple:

I've got the vehicle, just need the boat.

- Maltelec

- Master of the Forum

- Posts: 269

- Joined: Sat Nov 14, 2009 7:01 pm

- Boat Name: No Boat Yet

- Location: Cumbria, UK

- Contact:

Re: Triple Expansion Engine - Elliott Bay

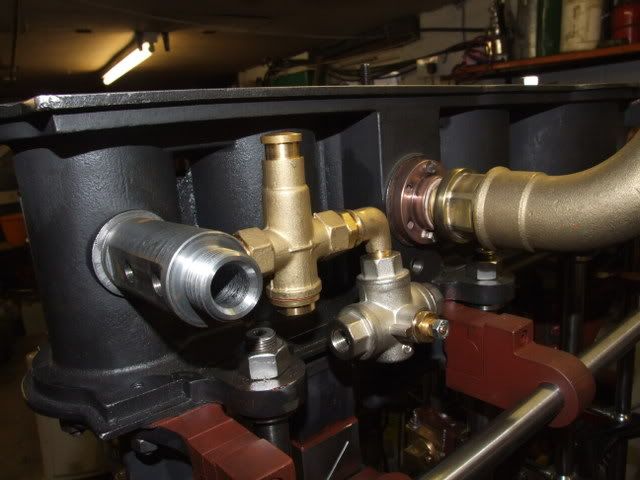

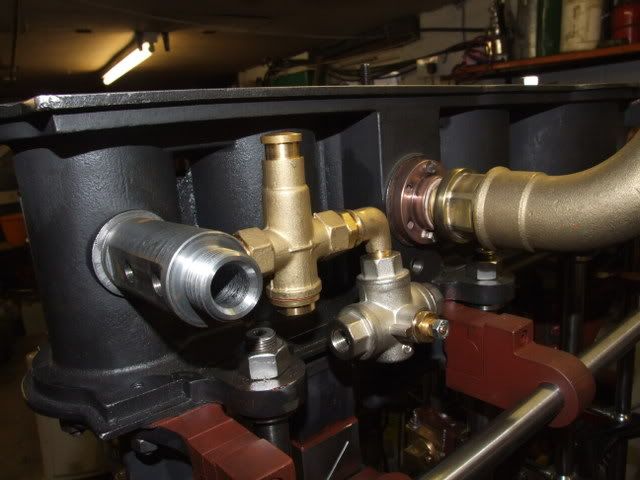

And here are 2 of the latest pictures:

I've got the vehicle, just need the boat.

- Maltelec

- Master of the Forum

- Posts: 269

- Joined: Sat Nov 14, 2009 7:01 pm

- Boat Name: No Boat Yet

- Location: Cumbria, UK

- Contact:

Re: Triple Expansion Engine - Elliott Bay

Here are the latest pictures and a video:

I've got the vehicle, just need the boat.

- Maltelec

- Master of the Forum

- Posts: 269

- Joined: Sat Nov 14, 2009 7:01 pm

- Boat Name: No Boat Yet

- Location: Cumbria, UK

- Contact:

Re: Triple Expansion Engine - Elliott Bay

Posted on behalf of Peter Cowie

Dear John,

Great to see your progress!

Here are two photos of the back of my engine showing the LP receiver. I made mine from 1/1/2" copper with elbows silver soldered. The second photo was taken soon after I ran the engine on the dynamometer. The condenser setup might interest you.

I was contemplating screwed fittings but the dogleg required to get the exhaust from the LP valve chest down past the receiver and over the wayshaft led me to the copper approach.

Lagging will give you some headaches here!

Kind regards,

Peter Cowie

Sydney

Australia

Dear John,

Great to see your progress!

Here are two photos of the back of my engine showing the LP receiver. I made mine from 1/1/2" copper with elbows silver soldered. The second photo was taken soon after I ran the engine on the dynamometer. The condenser setup might interest you.

I was contemplating screwed fittings but the dogleg required to get the exhaust from the LP valve chest down past the receiver and over the wayshaft led me to the copper approach.

Lagging will give you some headaches here!

Kind regards,

Peter Cowie

Sydney

Australia

I've got the vehicle, just need the boat.

- Maltelec

- Master of the Forum

- Posts: 269

- Joined: Sat Nov 14, 2009 7:01 pm

- Boat Name: No Boat Yet

- Location: Cumbria, UK

- Contact:

Re: Triple Expansion Engine - Elliott Bay

Some more pictures:

I've got the vehicle, just need the boat.