Page 2 of 3

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 2:12 am

by JonRiley56

Hi Scott,

Sage advice...................now I just need to figure out how to come up with $6500............I was going to seel my jeep with a plow to get the money for the 50% deposit, but that was before the 8 inches of snow we got today.......

jon

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 3:32 am

by DetroiTug

Jon,

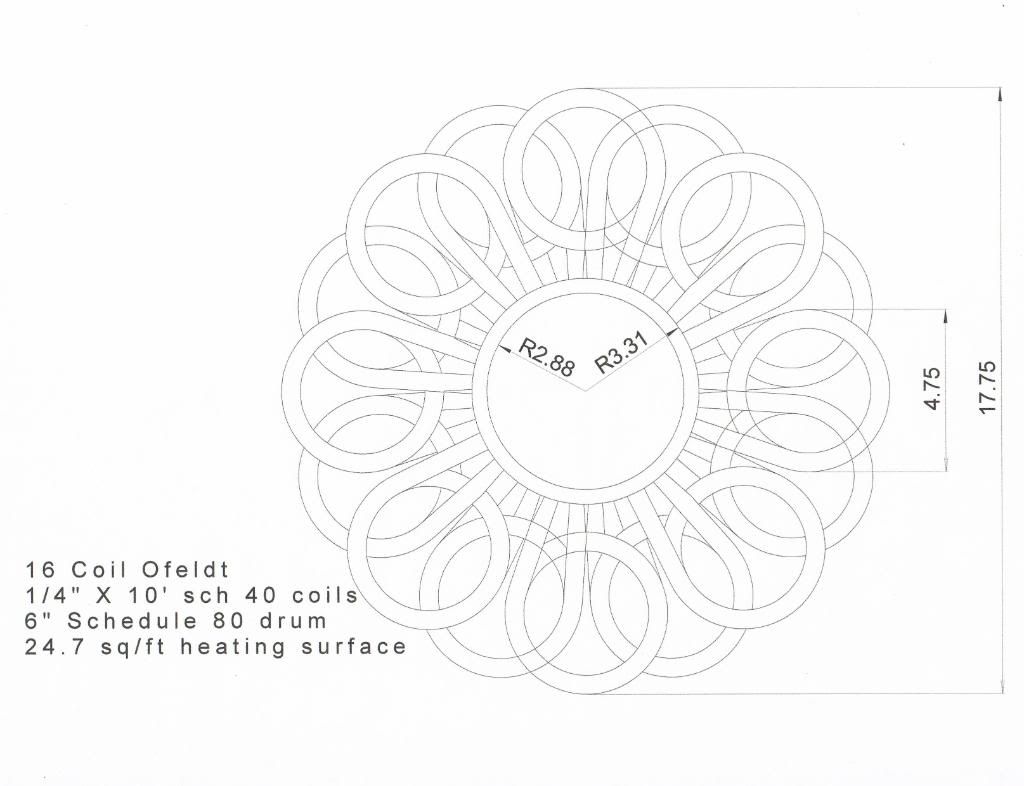

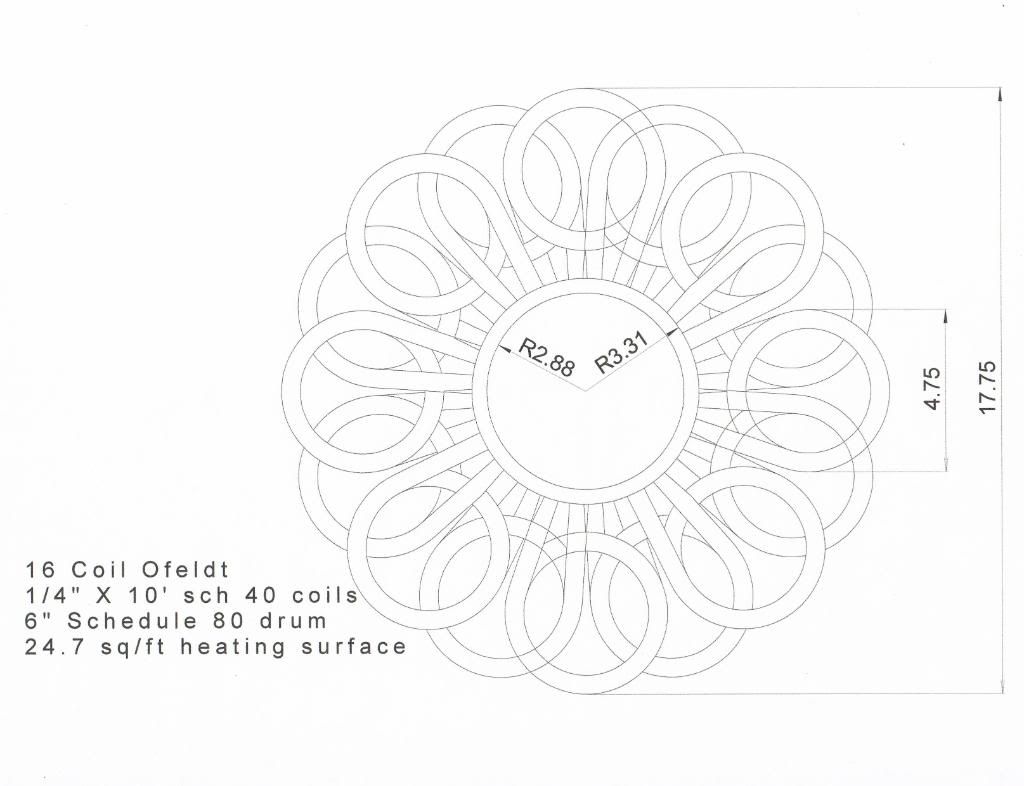

For one wanting to build their own boiler without a lot of pre-machining and welding - and cost, have a look at an Ofeldt. Of the three terms Cheaper/better/faster it's said we can only pick two of those for any device, but the Ofeldt comes close to nailing all three. The machining is just drilled holes that can be done in a drill press.

I'm in the process of building one now. The only obstacle is finding someone to wind coils. I joined the steam car club recently and there are two different people here within a few hours that have really good self-built coil winders.

The attached pic shows the basic plan. I've already wound the 16 coils and have the schedule 80 center drum and endcaps. About half the cost in materials that you mention above, and too there is very little welding, as all the tubes are welded internally. I would think you could find someone to weld this up for under 500. These boilers are very safe too. Only holds about 2 gallons of water. 2400 psi working pressure rating.

The boiler in the pic is only about 15" tall. It would run the hind-end off of a small single or compound. Great for oil firing too.

(Some of the lines are not trimmed in this drawing, it is for reference only)

-Ron

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 6:44 pm

by JonRiley56

Hey Ron,

Can you elaborae on what you mean by the welds being "internal" ? I assume the coils are copper, is that right ?

jon

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 8:30 pm

by DetroiTug

Jon,

The coils are schedule 40 black iron pipe. They just poke through the drum and get welded internally. I'm just learning the TIG welder (the reason I'm researching the technique), but I welded up a crankshaft for my buddy with the Uniflow twins Friday, it was very easy. Good to know as it was almost identical to how the tubes will weld in to the interior. Drum holes chamfered internally.

I was at the SACA Presidents' shop the other day and he has an original Ofeldt, that's how it was, just welded internally. The ends of the drum just had flanges for bolt on end-plates, and maybe a stay rod. But it was a really big boiler, probably 20 hp.

Getting back to the pipe, I used 1/4" to keep the overall coil diameter small, but it was expensive, 1/2" black iron pipe is a lot cheaper than 1/4", twice as big and half the cost. Copper has excellent heat transfer qualities, but if water level ever gets too low, or even under hard firing (Like the car guys do), it can boil the water out of the tube in a spot, the tube can fail quite easily. They had a few failed specimens from over the years, mostly copper monotubes there as examples. The steel coils are much more tolerant to hard firing and low water.

There are quite a few steam car folk over in your area, ask on the SACA forum, I'll bet someone has a coilwinder over there. The one Tom K has can wind 3/4" schedule 160 into a 6" diameter iirc. With drum, the overall diameter could be kept under 20", no problem.

-Ron

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 8:40 pm

by barts

A steel coiled ofeldt boiler is as close to bullet proof as one is likely to find. You can weld those tubes inside or outside; I'd use forged weld-on pipe caps for the ends. I used a reducer bushing to add a 4" diameter steam dome on Otter's boiler as well.

http://smaalders.net/bart/boiler.html

- Bart

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 9:12 pm

by JonRiley56

Hey Ron,

i sent you a pm

jon

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 10:23 pm

by DetroiTug

Bart,

That is the plan, to use the schedule 80 endcaps. I will cut them down in the lathe as the height is very critical where this is going.

The drum is ASTM A106 seamless.

The endcaps

And one of the coils, this is 10.5 feet of schedule-40 1/4" black pipe.

-Ron

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Sun Jan 22, 2012 11:08 pm

by barts

Very nice.... you could hydro the finished thing at 1000 psi if you liked. I did mine (copper tubes and all) at 400 psi, and my drum is schedule 40.

- Bart

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Mon Jan 23, 2012 8:15 pm

by JonRiley56

Hey Ron and Bart,

I am now musing over 2 sketches I bought from Reliable Steam on a couple of different sized Ofeldt boilers. The smaller one says it will supply steam for a "5hp compound or 7hp triple expansion engine". It is listed as having 21.9sq ft of surface area generating 7hp at 200psi.

Will that run my 3x4 M single cylinder ?

jon

Re: Elements for Square Foot calculation in Watertube Boile

Posted: Mon Jan 23, 2012 8:16 pm

by DetroiTug

Bart,

Yes, it should be very strong. I'll do a thread on it here as it could be used for a boat as well.

I really want to start on that yesterday, but I have to get the tug done first. If I don't, I know what will happen- Two unfinished projects.. I only have about two months work left on the tug at the present rate of task completion, which has been quite slow lately.

Thanks, Ron