This is the full story of machining the core boxes with happy end. I first had truble with the available hobby CNC mill I could use becaus it has a defect in the x-Axis. This ruined some parts or produced a lot of rework with putty and sandpaper.

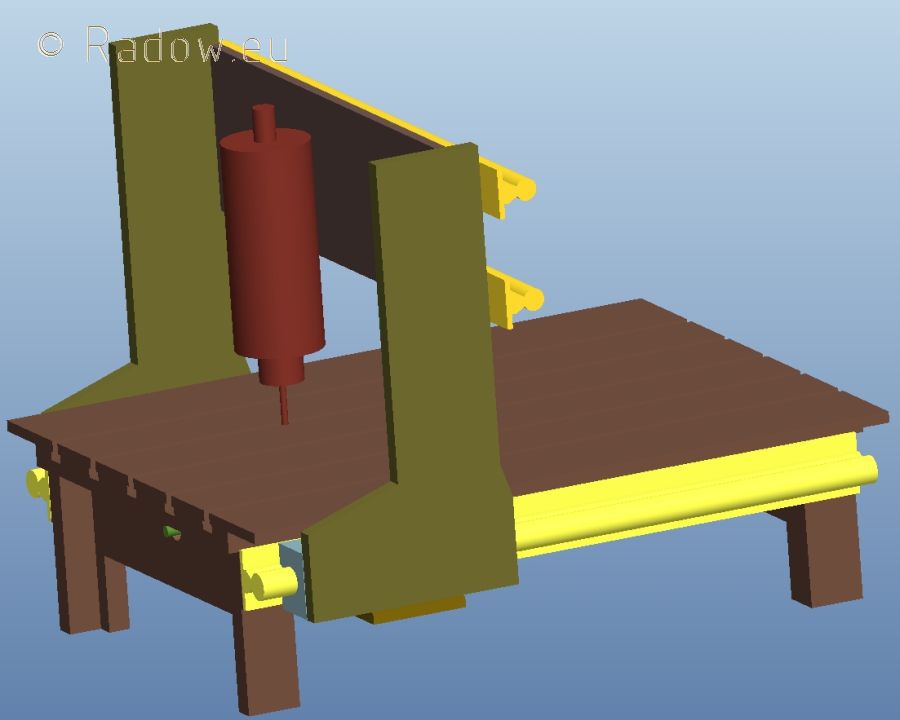

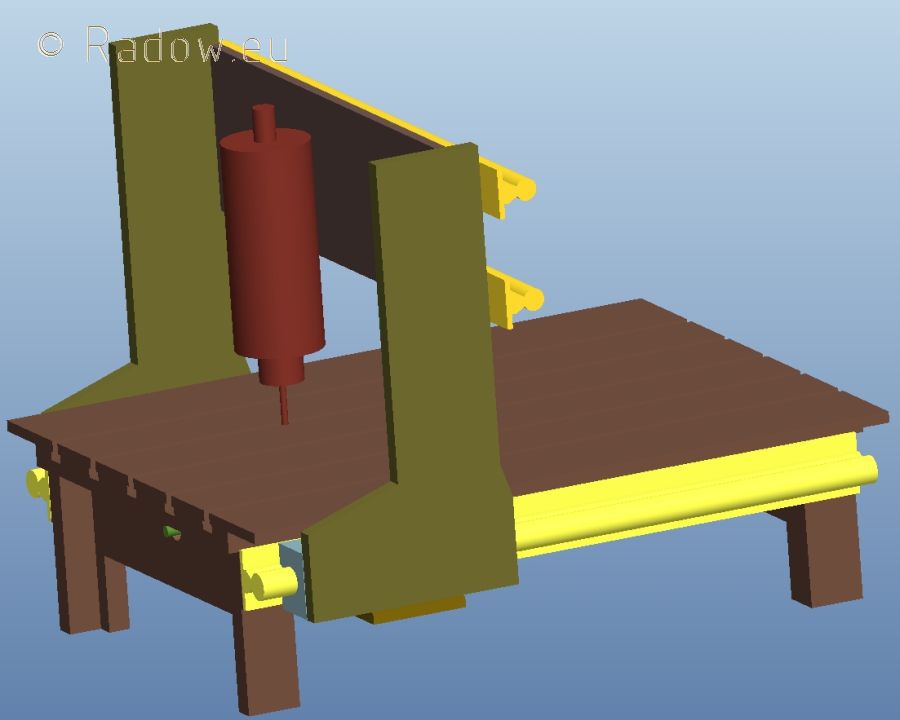

So I decided to build my own CNC-mill. I could enthuse my friend Dieter that he also would need such a machine. After my first rough design at the 12th of February 2012 we have made the agreement that he has to build the wooden pattern and I would have to take care of the casting and the machining of the table.

Dieter had finished his job 5 days later.

About 4 weeks later we could put his and mine 35 kg cast aluminum bases on the "big mill". My colleague Thomas (bottom left) did the machining according to my design.

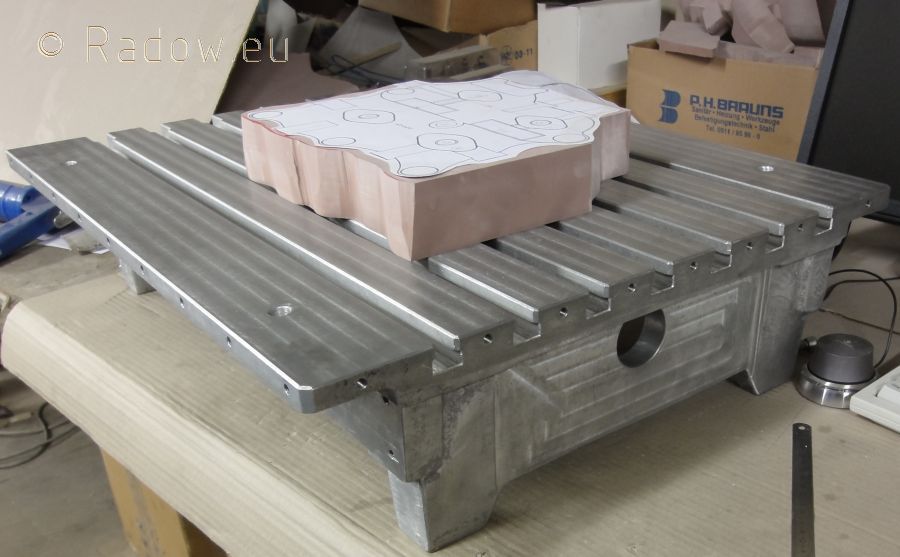

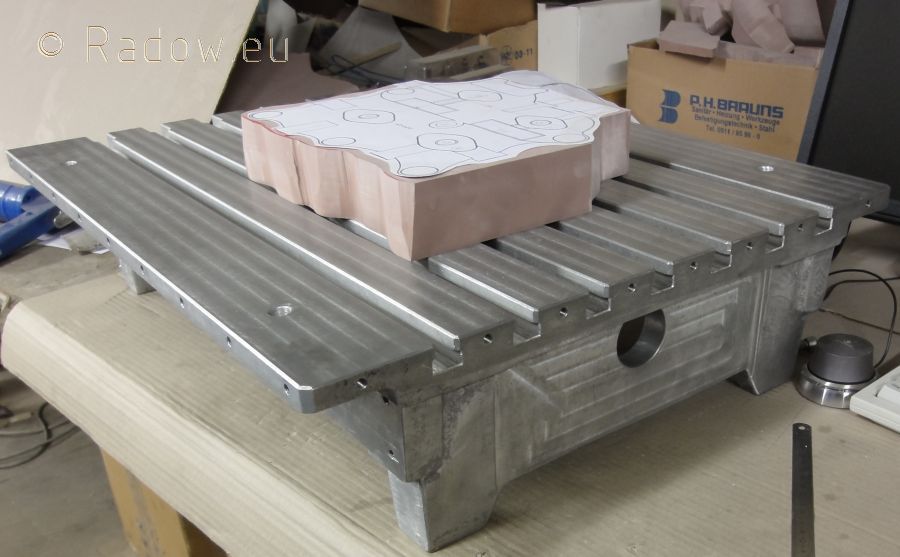

Here you can get an imagination of the possible workpiece size while placing my cylinder modell with it's raw material on the table. The table size is 600 x 500 mm (24" x 20") with a spindle travel of 400 x 400 x 130 mm (16" x 16" x 5").

My mill table is still sitting naked under the work bench as shown above - waiting for building capacity of mine. But my friend Dieter found some time to design and build the rest of his mill while I bought the stepper driver to combine it to a CNC mill.

This are videos from the first test runs in April 2012.

http://www.youtube.com/watch?v=Nl5pZhYb ... el&list=UL

http://www.youtube.com/watch?v=B315tnIS ... playnext=1

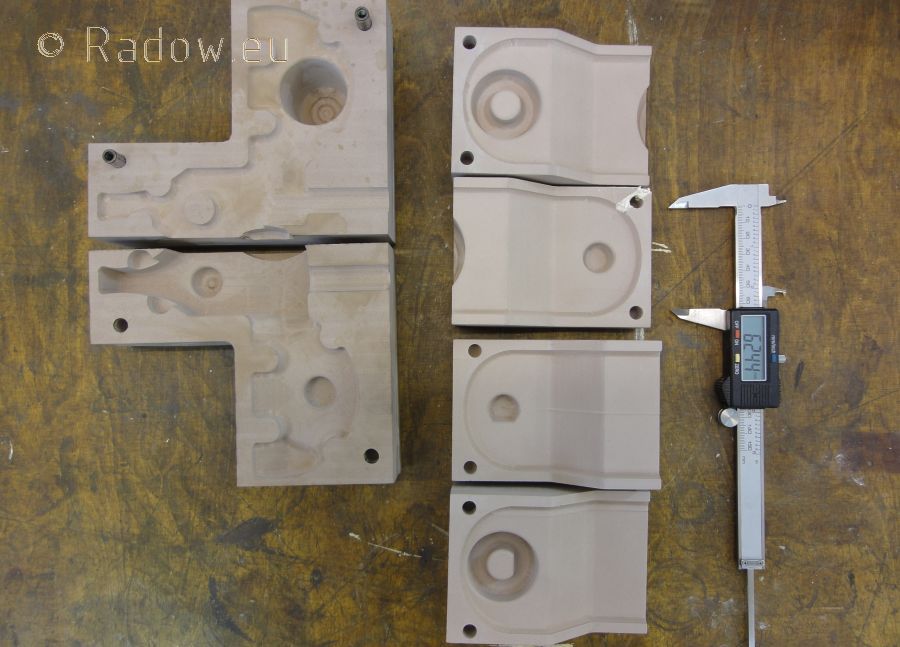

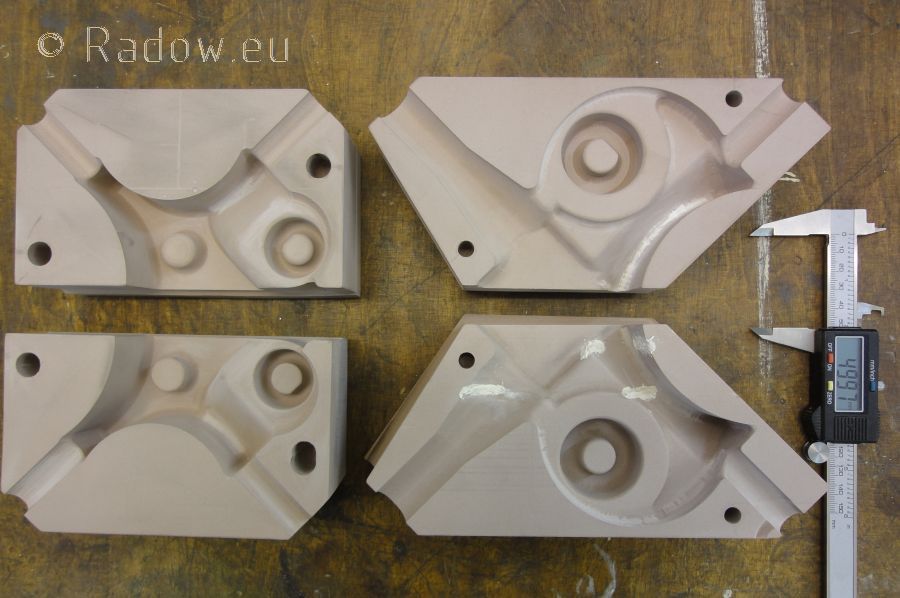

Last week Dieter delivered his mill into my shop. With it I could finish the cylinder core box making in a flash. I am operating it with a 5 mm ball nose mill at 17,000 rpm and a 1.1 kw 3 phase spindle. I limited the max travel to 3000 mm/min (120 inch/min).

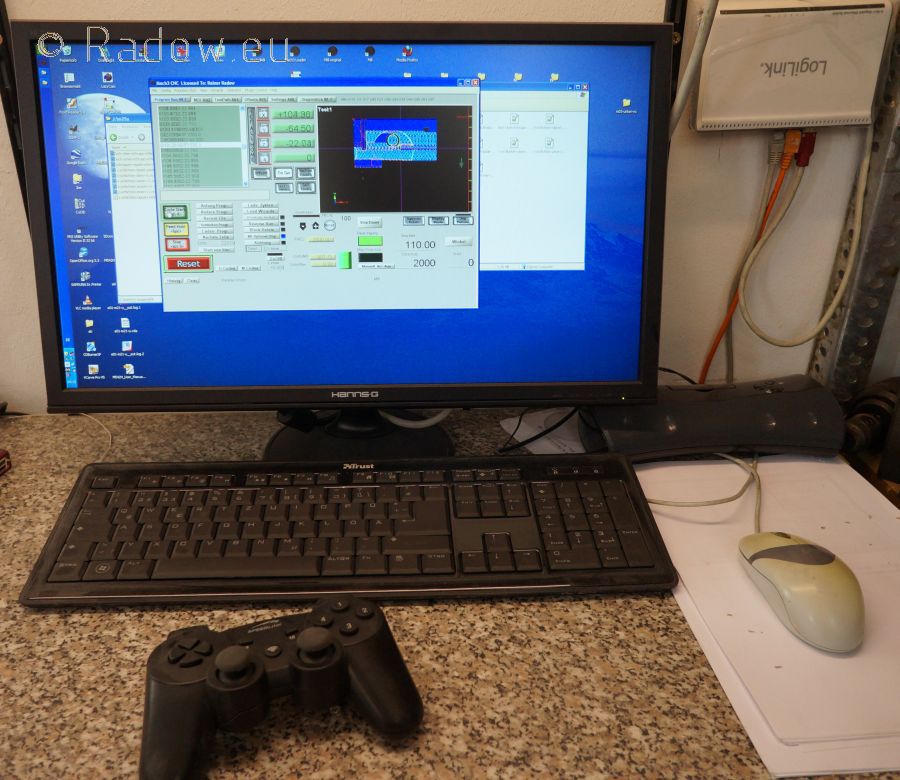

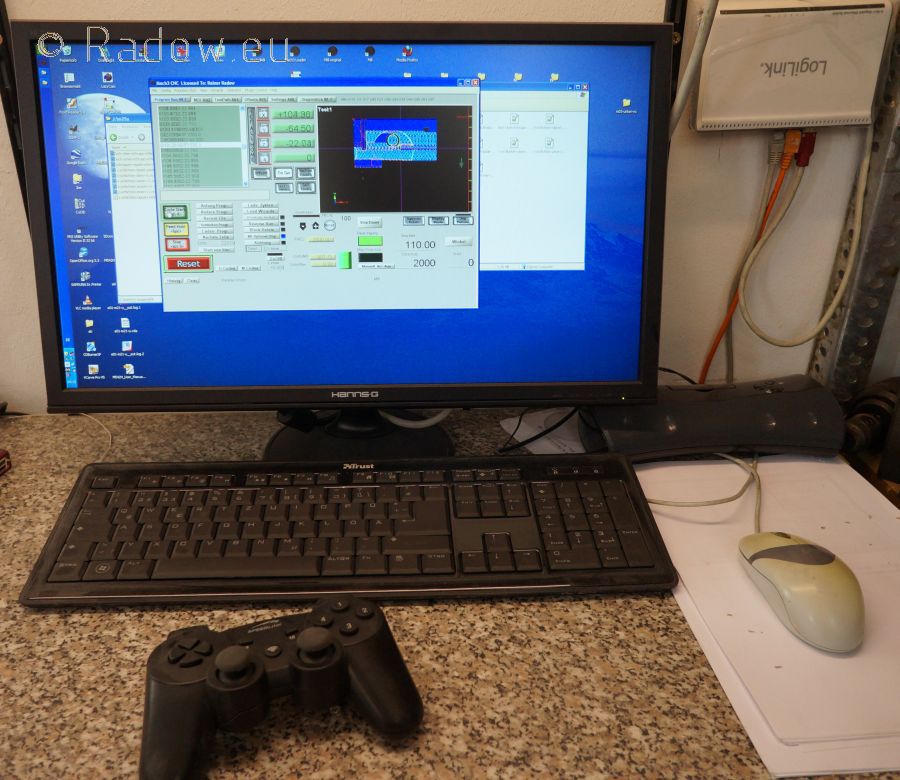

I am running the CNC-Mill with the common Mach3 software. To maneuver the mill by hand I coupled it with an ordinary 25$ wireless kids game controller.

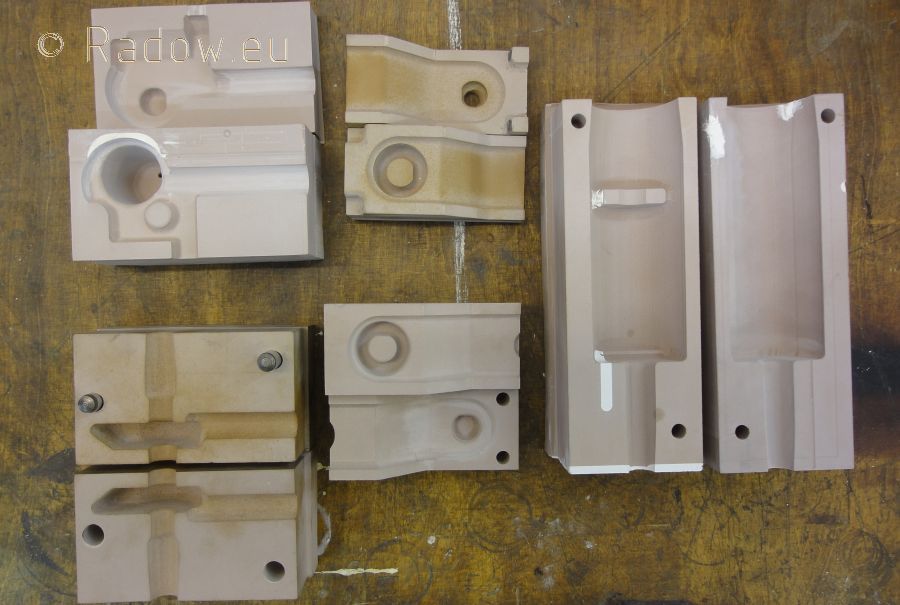

At least here you can see all ready machined cylinder core boxes