Page 17 of 22

Progress

Posted: Wed Jun 05, 2013 4:52 pm

by Rainer

Last steps:

Push rod guidance

Posted: Fri Jun 07, 2013 2:56 pm

by Rainer

I glued in the aluminum bar already and covered the triangle with a plywood top. Next week I can paint this unit and go further with the other gear.

Short paparazzi video of Emma from 2012

Posted: Fri Jun 07, 2013 5:12 pm

by Rainer

Today I found this in the internet...

http://www.yachthafen-klingenberg.de/wp ... a-2012.mp4

For me it looks like they mirrored the short video to make it longer...

Next step

Posted: Tue Jun 25, 2013 4:44 pm

by Rainer

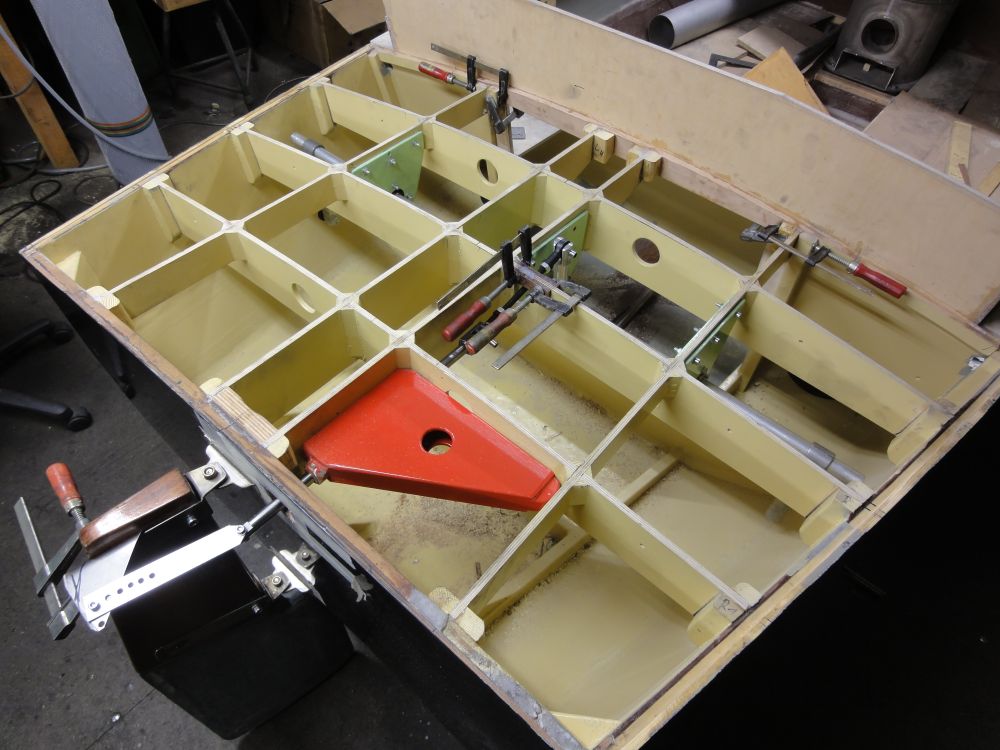

Today I finished all the work under the aft deck:

And glued in the base bearing holder of the left tiller:

It is made from plywood and some self made brass nuts which are glued into the wood.

This design keeps the floor clean.

Re: First core bockes

Posted: Thu Oct 31, 2013 5:34 am

by 87gn@tahoe

Any recent progress Ranier?

Re: First core bockes

Posted: Fri Nov 01, 2013 12:08 pm

by Rainer

You would be the first to know here!

Re: First core bockes

Posted: Mon Dec 30, 2013 1:33 pm

by PatJ

Rainer-

What are your building plans this year?

I am anxious to see that beautiful cast iron block turn into a running engine.

I know all good things take time, and I am sure you have been busy with life.

Pat J

Re: First core bockes

Posted: Mon Dec 30, 2013 10:53 pm

by Rainer

PatJ wrote:What are your building plans this year?

No more plans this year! I am (as in March 2013) in Italy preparing a nice New Yesars party with good friends - yes this are people without a lathe or mill and so there is no hope for any progress this year...

I am anxious to see that beautiful cast iron block turn into a running engine.

So we are at least two with this feelings

During saving and organizing this years pictures I found a lot of non steaming stuff - a DY Drone - lots of vacations and weekend trips with the family - 4 weeeks in the USA - no progress in the steam projects - even Emma stayed cold the full season - this year was runing super fast...

But I finished a small cnc mill project which enables me to mill smaler parts at home again (x-y-z travel = 400 x 220 x 500 mm) and hope to finish my also long term project of my own home stationed pattern making cnc mill (x-y-z travel = 380 x 420 150 mm) with water cooled 2.2 kw HF China milling spindel.

So 2014 should be at least the year to make the engine base pattern and get it poured.

All the best for you and your family and a "steamy" 2014

Greatings from Italy

Rainer

Re: First core box

Posted: Mon Jan 13, 2014 11:23 pm

by Rainer

But I finished a small cnc mill project which enables me to mill smaler parts at home again (x-y-z travel = 400 x 220 x 500 mm) and hope to finish my also long term project of my own home stationed pattern making cnc mill (x-y-z travel = 380 x 420 150 mm) with water cooled 2.2 kw HF China milling spindle.

The old base - fresh grinded - with ball screws and 400 Watt 50 Volt DC-servo motors on all 3 axis.

Old milling gear box with MK 3 tool taper and 1 HP 380 Volt 3-phase motor - at the left.

We are lucky to have 3 phase 380 Volt in virtually every German household as standard for the electric stove and baking oven in the kitchen. If you are lucky you can "pick" the 3 phases direct in the cellar - as a student I also had a free wiring from the kitchen in the rented flat through a dead chimney into the cellar.

- 2013-11-09.214642-kk.jpg (96.12 KiB) Viewed 9932 times

New z-axis with German standard 1/2 Liter returnable beer bottle as scale.

The z-axis break is not mounted here.

- 2013-11-18.225700-k.jpg (130.12 KiB) Viewed 9932 times

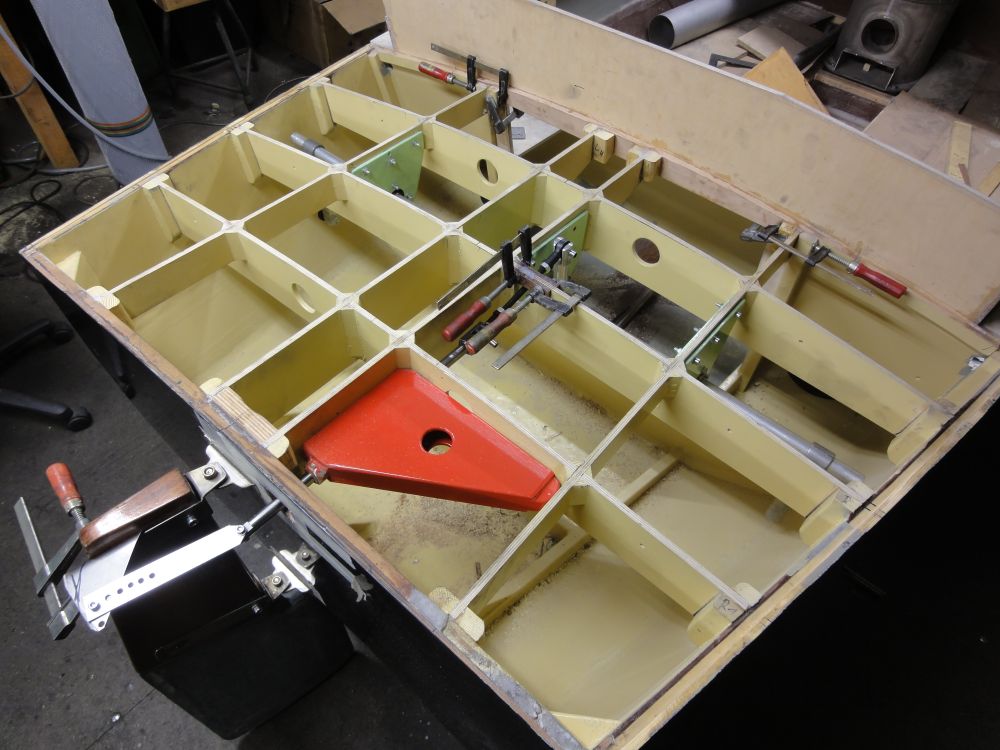

Self made guide way protection from glas fabric.

- 2014-01-04.204143-k.jpg (116.02 KiB) Viewed 9932 times

"Cannot add another attachment, 3 is the maximum...."

Re: First core box

Posted: Mon Jan 13, 2014 11:33 pm

by Rainer

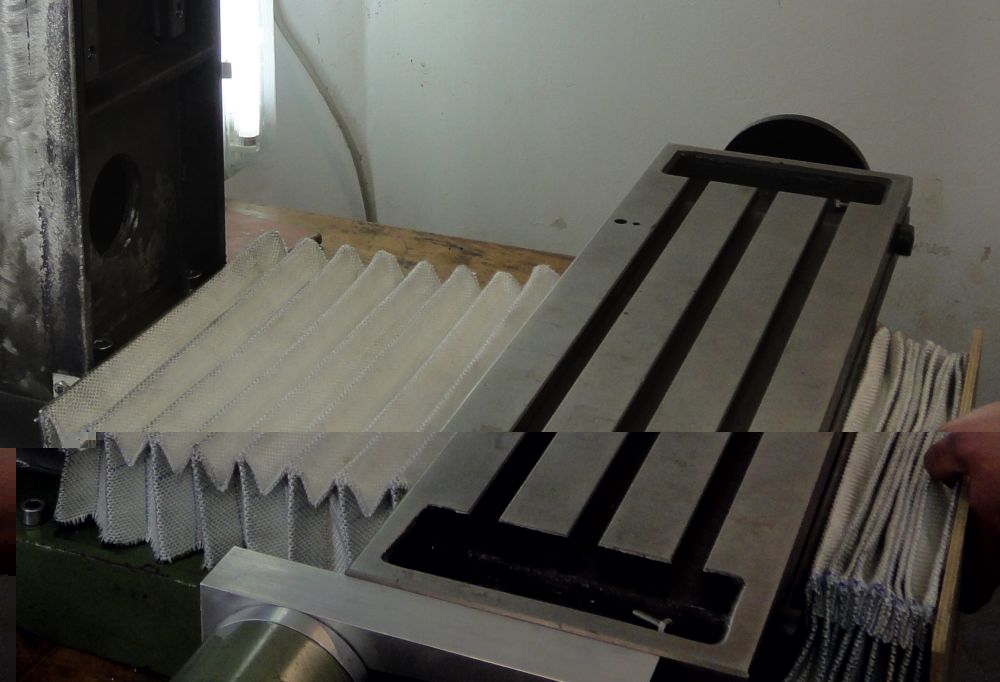

It's working:

- 2014-01-04.210620-k.jpg (97.24 KiB) Viewed 9931 times

Accuracy is quite good - less than 0.04 mm = 0.0016 inch - over a distance of 400 mm = 15.8 inch measured with a marbel triangle.

- 2014-01-12.154845-k.jpg (96.34 KiB) Viewed 9931 times

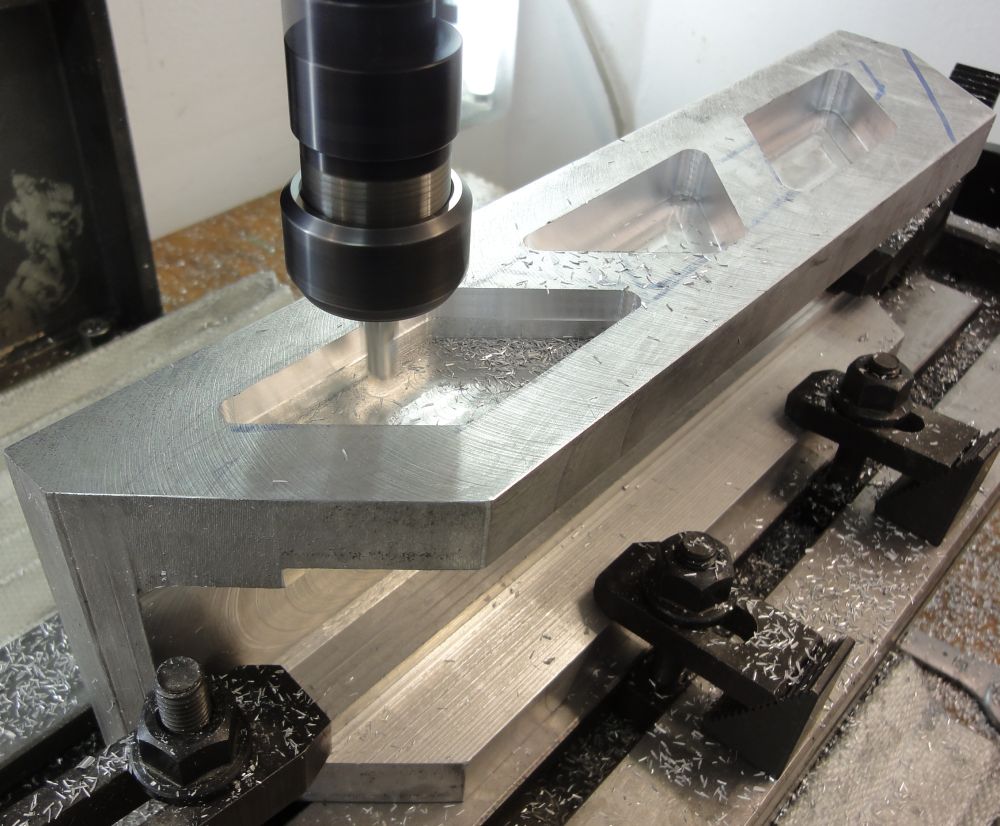

This is the Z-Axis for my pattern making cnc mill - 400 mm long - milled of the home made cnc-mill

- 2014-01-10.221755-k.jpg (146.91 KiB) Viewed 9931 times

As you can see - lots of metal flakes - but no steam engine or pattern - in the moment... Hope to change this!