Page 20 of 22

Re: First core box

Posted: Wed Feb 12, 2014 7:58 pm

by Rainer

Mike Rometer wrote:really does not have much trouble starting without the bypass - Simpling valve.

This is the case when you have a defect HP valve which let enought steam through to start the LP...

Pattern Mill

Posted: Sun Feb 23, 2014 12:28 am

by Rainer

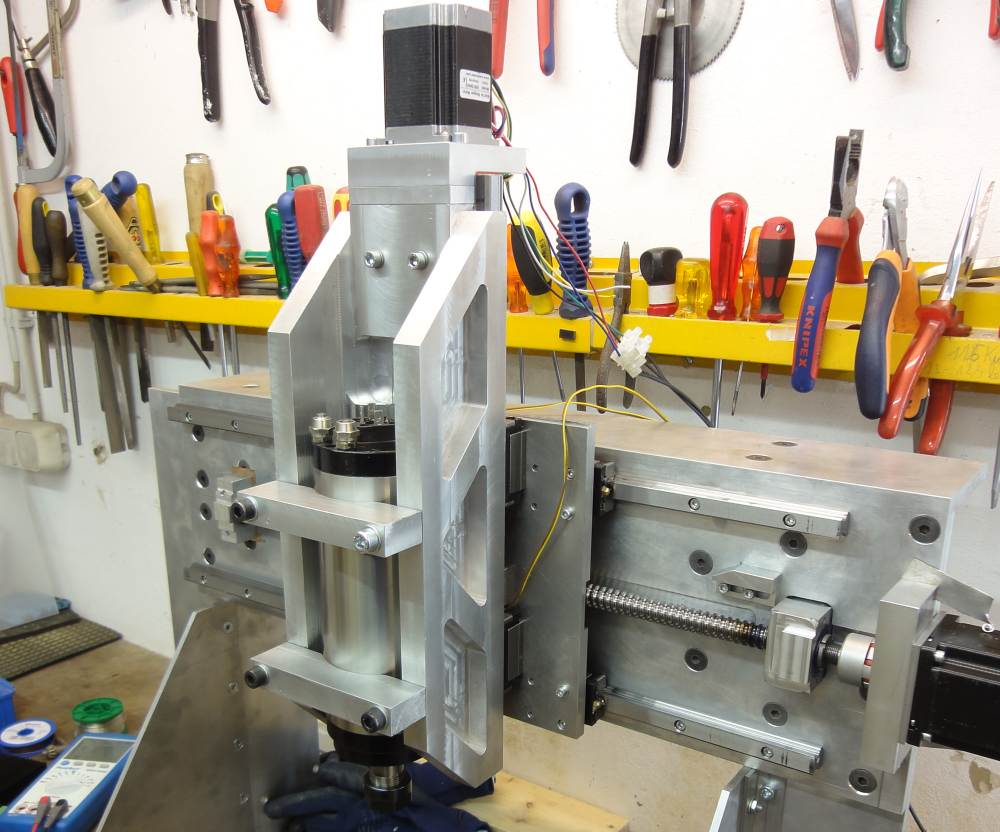

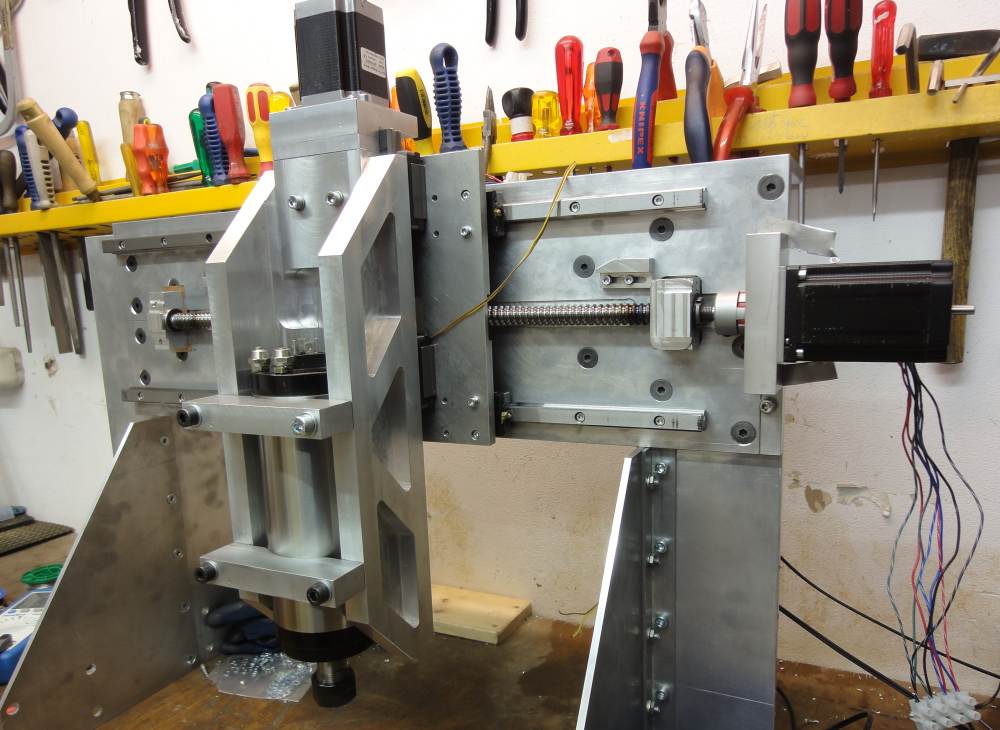

Some progress with the pattern CNC-Mill:

- 2014-02-23.000002-k.jpg (123.17 KiB) Viewed 21673 times

160 mm Z travel plus the possibility to move the spindel up and down in its fixture to archive the full workspace range of 200 mm unter the x-axis bridge

- 2014-02-23.001122-k.jpg (113.78 KiB) Viewed 21673 times

Did all machining with my home upgraded CNC-mill.

- 2014-02-23.000106-k.jpg (164.19 KiB) Viewed 21673 times

Posted: Sun Feb 23, 2014 7:38 am

by 87gn@tahoe

With building your pattern mill, your regular job, and the amazing updates and improvements to your website you must have no time for anything else!

Re: First core box

Posted: Sun Feb 23, 2014 2:21 pm

by PatJ

That is a nice looking machine.

Well done.

Pat J

Re: First core box

Posted: Sun Feb 23, 2014 5:21 pm

by PeteThePen1

Hi Rainer

That looks an excellent machine. Well done!

If you should decide to build a better Mark II version, can I have the old one???

Regards

Pete

Mill

Posted: Wed Feb 26, 2014 2:39 pm

by Rainer

Thanks for all the warm words. Have it together and at the table. Now I have to align everything. Not a problem in the range of some +/- 0.5 mm (0.02 inch) but it should be

at least one power better (= 0.05 mm/0.002inch). Therefore I have to think about an adjuster.

- 2014-02-26.080000-k.jpg (36.01 KiB) Viewed 21622 times

Re: First core box

Posted: Thu Feb 27, 2014 2:25 am

by barts

If your errors are consistent, you may find it simpler to construct a error model of the device in software and do correction that way. I've used that technique to correct CMM errors with good results. If you can automate creation of the error terms, renewing the maps after disassembly (or crash!) is much easier. I used squareness terms, straightness maps (interpolated) and linear axis roll terms to compute the forward & backward kinematics of the CMM; by calibrating with a laser interferometer we were able to hold ~.005" over a 360" x 36" x 36" working envelope until the next time someone banged it with a forklift or the factory temperature changed.

- Bart

Re: First core box

Posted: Thu Feb 27, 2014 12:52 pm

by fredrosse

Bart, what language are you writing in? It's all "Greek to me"

Re: First core box

Posted: Thu Feb 27, 2014 1:48 pm

by DetroiTug

Rainer is using Mach3 as the CNC control program I think. It has "screw mapping" where errors can be corrected over distance and it also has "backlash compensation" where a value can be set for the amount of lost motion in traverse, the machine quickly moves across that on direction change, the positional DRO does not reflect this movement. Ideally there should be none, but that is impossible even on the most expensive most precise machines made. Real world factors like thermal expansion, friction, lines of force, deflection of components etc prevent true "zero backlash".

-Ron

Re: First core box

Posted: Thu Feb 27, 2014 4:03 pm

by Oilking

Sounds like it's FUZZY logic to me?

If I understand any of it, it sounds like how the roler path error on a Naval gun mount was corrected for in the fire control computer even in the day when they were all gear cam, and lever clock works.

So it's easier to write an error code for the X & Y axis than rescrape the bed, and ways! Mabe I can convert my 1917 Monarch lathe to CNC so I won't have to have the ways planed to stop it from cutting a taper?

Well it was a thought.

Dave