Page 3 of 3

Re: 90 deg-- 180 deg crank

Posted: Fri Jan 29, 2016 3:14 am

by Lopez Mike

All news to me on the left hand leading locos. Great info.

I'm not sure such a beast as a Climax is entirely considered a locomotive. Perhaps a collection of locomotive parts flying in loose formation. The only one I've been around was a hazard to bystanders with the odd nut or bolt leaving formation without permission.

Re: 90 deg-- 180 deg crank

Posted: Fri Jan 29, 2016 11:29 pm

by gondolier88

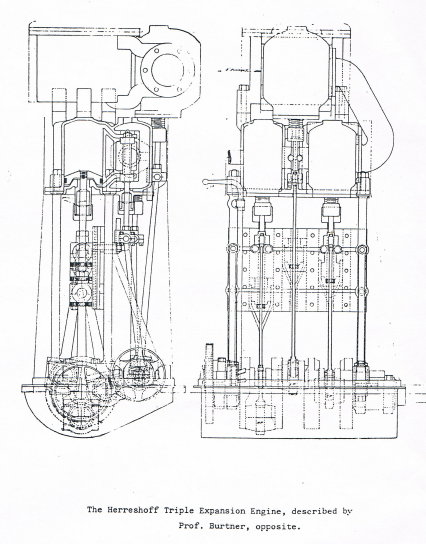

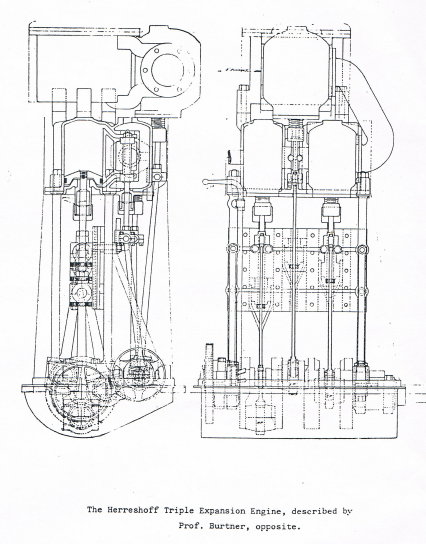

TahoeSteam wrote:Herreshoff's steeple triple-expansions had 3 cranks and they weren't at 120* speration

I'm interested how a steeple triple could have three cranks- I don't know the Herreshoff engines well, have you got a link or a photo?

Greg

Re: 90 deg-- 180 deg crank

Posted: Sat Jan 30, 2016 8:04 am

by TahoeSteam

gondolier88 wrote:TahoeSteam wrote:Herreshoff's steeple triple-expansions had 3 cranks and they weren't at 120* speration

I'm interested how a steeple triple could have three cranks- I don't know the Herreshoff engines well, have you got a link or a photo?

Greg

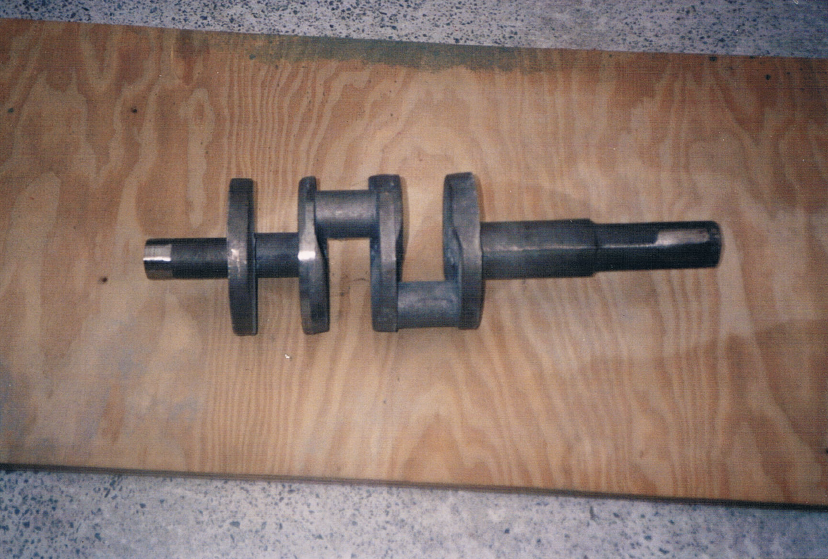

Three cranks, AND only two main journals!

Re: 90 deg-- 180 deg crank

Posted: Sat Jan 30, 2016 7:54 pm

by gondolier88

Apologies for autocorrect 'could' should have been 'couldn't' in my last post.

I see now that the con rod on the centre cylinder is longer than the other two, I'm looking on my phone so I can't tell from the end elevation what the anglular offsets of the cranks are- do you know?

Do you know if the crankshafts on the Herreshoff engines were cast or forged?

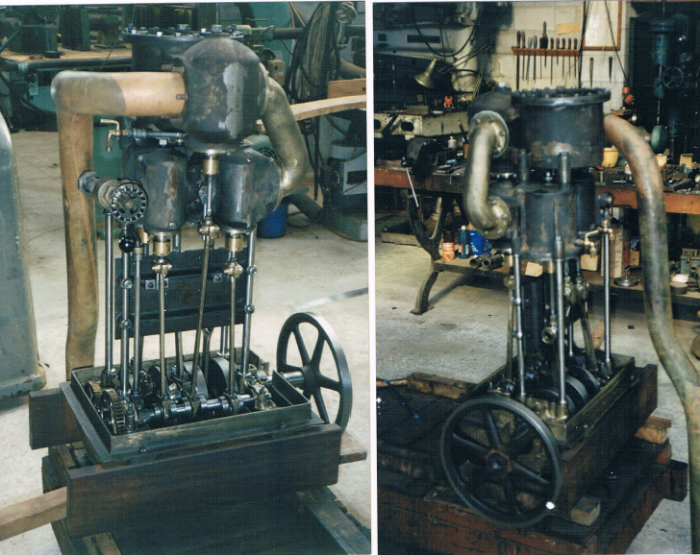

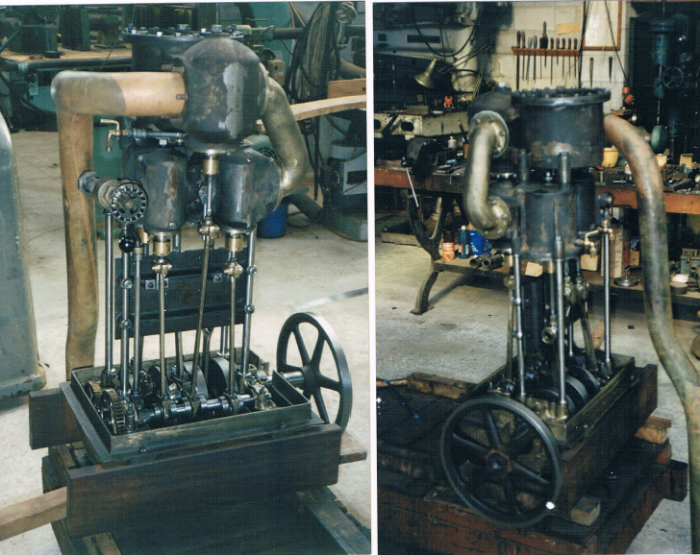

An interesting engine- is this the replica that Chris MacMullen was putting into a replica Herreshoff launch?

Greg

Re: 90 deg-- 180 deg crank

Posted: Sat Jan 30, 2016 11:22 pm

by TahoeSteam

Greg,

The rods that can be seen readily are actually the con rods for the valves. The actual cylinder connecting rods are all the same length, the LP having a longer piston rod instead.

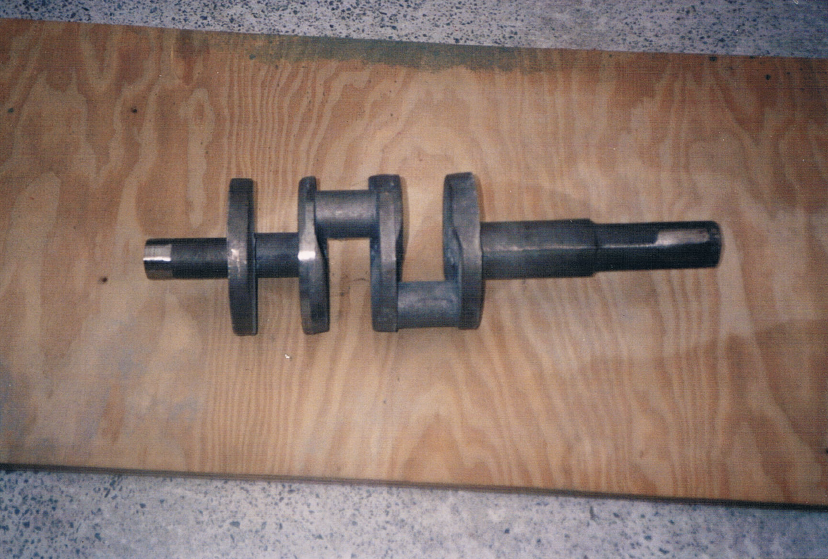

I believe those are photos of Chris' engine, and crank. In some correspondence with him a while back I recall him saying he kept having issues with cracks in the cranks. I am not sure what methods were used for the original cranks, but from my understanding Chris went through great lengths to replicate everything with the correct materials and methods.

I would think any crank cast, forged, or billet even would have trouble with deflection and bearing life having only two mains.

I can imagine those engines caused an awful din with the straight-cut gears for the valve gear.

Re: 90 deg-- 180 deg crank

Posted: Sun Jan 31, 2016 9:43 am

by Mike Rometer

TahoeSteam wrote:

I would think any crank cast, forged, or billet even would have trouble with deflection and bearing life having only two mains.

What you say is true. Years ago people used to race Austin Seven cars, in all sorts of events such as hill climbs. Whilst a great little 4 pot engine for gentle road use, once tuned to get a bit more out, they could be heard to knock at revs exceeding the design level by a touch too much, and this was determined to be the two centre pistons hitting the flat (side-valve) head. Two bearing crank! Crank deflection is a fact of engineering life.

Re: 90 deg-- 180 deg crank

Posted: Sun Jan 31, 2016 3:11 pm

by Lopez Mike

The venerable Atomic Four, marine engine in zillions of small sailboats, had only two main bearings and gave good service. BUT, it ran very slowly and didn't put out very much power. Smooth though.

By I.C. engine standards our engines are idling and/or lugging. I wouldn't have it any other way. No buzzing for me, thank you.

Re: 90 deg-- 180 deg crank

Posted: Sun Jan 31, 2016 5:12 pm

by gondolier88

TahoeSteam wrote:Greg,

The rods that can be seen readily are actually the con rods for the valves. The actual cylinder connecting rods are all the same length, the LP having a longer piston rod instead.

I believe those are photos of Chris' engine, and crank. In some correspondence with him a while back I recall him saying he kept having issues with cracks in the cranks. I am not sure what methods were used for the original cranks, but from my understanding Chris went through great lengths to replicate everything with the correct materials and methods.

I would think any crank cast, forged, or billet even would have trouble with deflection and bearing life having only two mains.

I can imagine those engines caused an awful din with the straight-cut gears for the valve gear.

Thanks- I'll have a look at the photos later on the laptop! There are dozens of Cyril Taylor's compound and twin designs around with two main bearings only- they have a central shaft joining both throws that is around 150% crankshaft diameter. I believe these were his early design, and later ones were all made three bearing engines- Steamboat Jack would be the best person to comment on the evolution of the Taylor designs I dare say.

Greg

Re: 90 deg-- 180 deg crank

Posted: Mon Feb 01, 2016 9:46 am

by steamboatjack

The Taylor engines I build use three main bearings, and usually with longer (and larger diameter) first & third bearings than original. I have a set of modern drawings for the 2.5 ins twin now which I can let anyone have for a modest sum, although castings are as far as I know not available as the SBA were arranging this but so far have not come up with any?

The patterns would be easy to make for this should anyone wish to do it.

Regards

Jack