Page 3 of 5

Re: Onboard Condenser

Posted: Thu Jan 17, 2013 1:28 pm

by JonRiley56

Well now, there is no need to be hurtful

............ Another reason I am going with the inboard condenser is I will be running on pretty cold seawater. The likelihood of getting "over cooling" of the condensate is pretty high. If I run through an inboard condenser that has a pump supplying water to the shell, I can toggle it on and off for water changes in the condenser to try and keep my return to the hotwell at 140f plus.

I do not have a preheat set up at this point, I am pulling the little inline unit I have out of the circuit for ease of plumbing for this season. I was pulling some air somewhere and it was causing me problems. I think I have actually come up with a layout for the water circuit that only involves 3 valves, it will make things much neater. I am going with the "art deco revival minimalist" theme for 2013.....

I am switching over to the steam driven southworth pump that Ron is building for my boiler supply so I am not overly concerned about supplying the pump with hotwater.

jon

P.S. - On a separate topic, i have seen a couple of pics where it looked like there was a small expansion canister in the water loop, probably to minimise water hammer issues. Is any one doing that ?

Re: Onboard Condenser

Posted: Thu Jan 17, 2013 3:22 pm

by fredrosse

From a previous post here: "salt inside is bad in the long run but I don't see it as causing the boiler to be damaged by a busted condenser. "

That statement may be true for a steel boiler, but definitely not for a stainless steel boiler. Chlorides above a few PPB (parts per billion) is considered bad for a stainless steel boiler, and sea water is 35,000 PPM (parts per million) salt (Sodium Chloride), so even the smallest leak of sea water into the condenser should be avoided.

Re: Onboard Condenser

Posted: Thu Jan 17, 2013 7:56 pm

by 87gn@tahoe

barts wrote:The only reason I'd go to an inboard condenser would be to reduce the chance of damage due to logs, beaching, etc. The large boat will have a nice heavy pipe well protected by the keel... or just part of the keel being galv. steel and a condenser

.

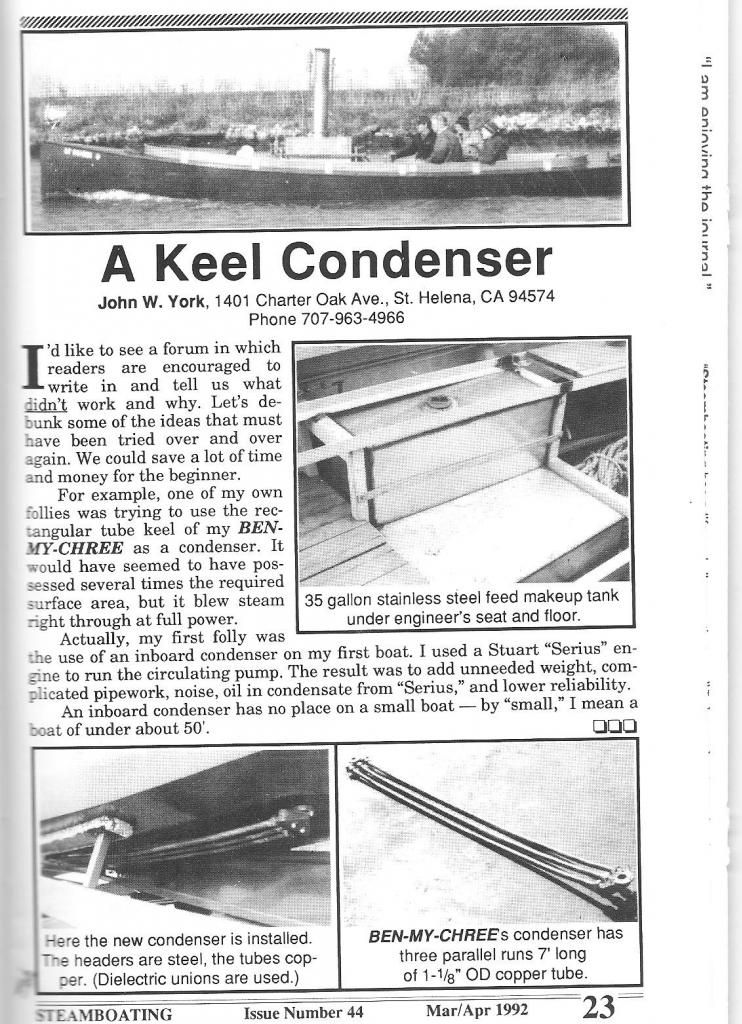

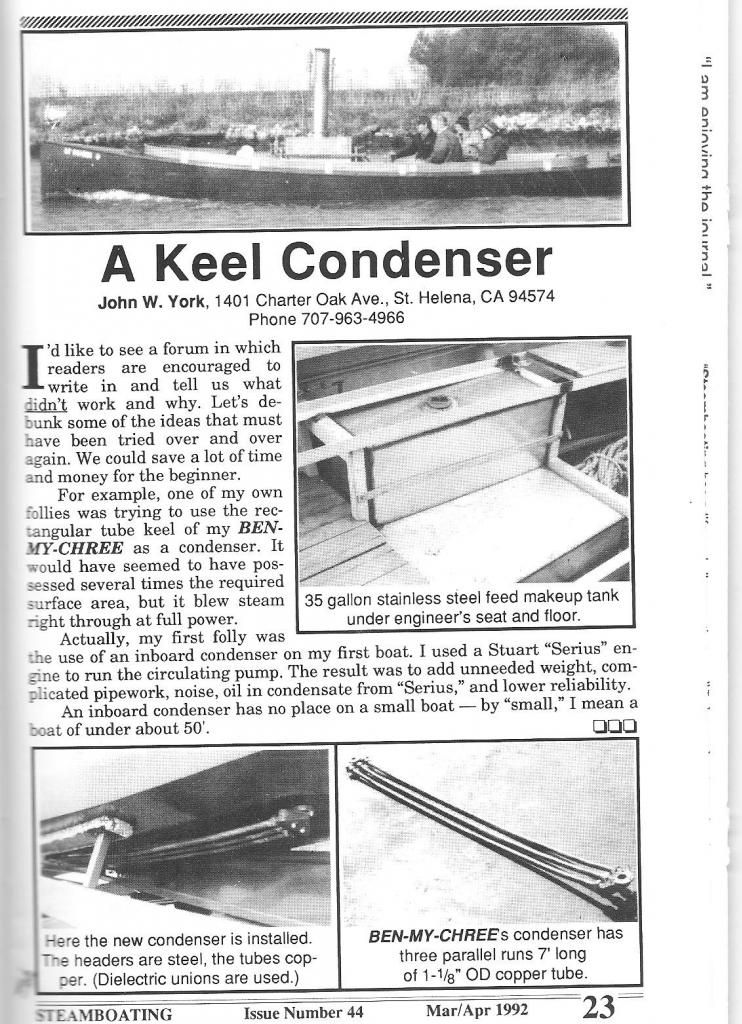

Didn't John York originally try to use his keel as his condenser, but eventually moved to a regular manifolded condenser? I think there's an old steamboating magazine clip about it...

Edit> Here it is... John also seems to have a strong opinion (as usual) about inboard condensers:

Re: Onboard Condenser

Posted: Thu Jan 17, 2013 8:40 pm

by Lopez Mike

Fred is so right about stainless steel and salt. Bad juju! But I'm not that big on stainless anyway except for pretty places.

Your idea of being able to adjust the amount of cooling is certainly attractive. My hot well is far from hot right now and the best idea I have come up with is to insulate part of it and see what happens. Hard to adjust on short notice though.

Most of the time I'm navigating on cold sea water but I'm concerned about getting on some estuary and not having enough condenser capacity. If needed, I suppose I could have two keel runs in parallel and close off one of them when in cold waters.

Any ideas from the group?

Mike

Re: Onboard Condenser

Posted: Thu Jan 17, 2013 11:27 pm

by barts

Most of our engines are exhausting steam at fairly high quality. Since the latent heat of vaporization is high, one can cool the water a lot and bring it right back to exhaust temperature using a feed water heater. Full size plants don't do this because they expand down to condenser vacuum; we're still plenty hot. Hotwell temperature is only interesting for reducing oxygen content, but since exhaust temp is likely to be 250+F in most of our plants, it's pretty easy to add a line from after the feed water heater teed into the hotwell float valve line; put a needle valve in both cool and hot water lines and adjust % of bypass that comes from hot side to suit. There's plenty of wasted heat in the exhaust to reheat the water coming back from the too-big condenser. Extra points to the fellow who uses a bit of propane in against a spring to adjust the temp of his hotwell automatically against variations in water temp, load, etc .

- Bart

Re: Onboard Condenser

Posted: Fri Jan 18, 2013 3:04 am

by SL Ethel

I'll bet an automotive thermostat would work well for bypass control if you could find one designed to run a bit cooler than the usual 190 degrees.

Re: Onboard Condenser

Posted: Fri Jan 18, 2013 5:16 am

by Oilking

The Navy standard for propulsion boilers is 2.0 epm for chloride that worksout to 116 ppm if the total chloride contibition is from sea salt (NaCl). For auxillary boilers (~150 psi) the limit for chloride is 15 epm or 877 ppm. (ppm=LB/Million LB H2O)

The aux boilers are more in the range of what our kind is dealing with. These are also going to be carbon steel tubes in all the wetted areas. The issues of embrittlement and chloride corrosion in stainless was clearly explained to us in boiler & feedwater testing school, and that's why stainless is only used for supperheaters in Navy boilers. I am suprised at how often I hear of boilers being built with stainless tubes. On one site I saw a statement that copper tubing was not allowed by ASME code, but stainless was!? (Fred feel free to jump in). Maybe by the name stainless it runs counter intuitive to the fact that carbon steel would be better in this application.

I am including this site which shows what real salting up is!

http://www.moore-mccormack.com/SS-Urugu ... -War-1.htm

Salt is only good if it's on popcorn or used to cure salmon.

Dave

Re: Onboard Condenser

Posted: Fri Jan 18, 2013 5:42 am

by fredrosse

From posts on this forum, Oct 2010: "The ASME Boiler Code specifically prohibits use of stainless steel for wetted parts of a power boiler. There can be exceptions to this rule, but it would be prudent for you to use materials acceptable to the Code."

From posts on this forum, 2011: "The ASME Boiler & Pressure Vessel Code prohibits the use of "Austenitic Stainless Steels" for wetted parts of the boiler. This includes the 200 Series and 300 Series Stainless Steels. The most common stainless steels encountered are Types 304 and 316, probably 90+ % of the stainless steel used is 304 or 316, and they are prohibited for use in the wetted parts of the boiler. Other common grades: 201,203, 301,302, 303, 304L, 305, 308 (weld wire), 309, 316L, 317, 321, 347.

These stainless steels however are commonly used as tubing in various liquid heat exchangers, fluid system tubing, instrument tubing, etc. They are legal for the "non-wetted" parts of a boiler, such as superheater tubing."

From posts on this forum, Sept 2010: "The American Society of Mechanical Engineers (ASME) produces the boiler code rules used in many countries. Their boiler code prohibits use of copper or copper alloys at any temperature exceeding 406F. This temperature corresponds to saturated steam at 250 PSIG, about twice the pressures used in many steam launches."

So much for the ASME rules, although I have heard that some stainless steel boilers have held up well in boiler service. I even had a flash steam generator with 304 stainless coils, but that had a 5000 PSI test pressure, and only used distilled water for feed, running at 200 PSI.

Re: Onboard Condenser

Posted: Fri Jan 18, 2013 7:00 am

by Oilking

Fred,

This is the forum where I saw the discusion of copper vs. stainless for boiler tubes.

http://www.chaski.org/homemachinist/vie ... =8&t=93842

The fifth post contained the following quote:

"BTW the ASME code doesn’t recognize rolled in copper tubes. But they do recognize stainless steel."

This ran counter to what I have understood and what you have so clearly stated once again.

The Tojan Nuclear Power Plant a few miles up river from me, was forced into shutdown about 10 to 15 years early due to repeated problems with stress cracking causing leaks in the stainless steel steam generator tubing. Who cares about salt when you have a few neutrons flying around.

Roled in copper? Any thoughts on that?

Thanks

Dave

Re: Onboard Condenser

Posted: Fri Jan 18, 2013 5:01 pm

by JonRiley56

Getting back to the condenser conversation, take a look at this little doohickey. Since I am going to run an electric pump I could use this to toggle it on and off based on the temp of my hotwell.

http://www.thermomart.com/index.php?rou ... uct_id=149

jon

............ Another reason I am going with the inboard condenser is I will be running on pretty cold seawater. The likelihood of getting "over cooling" of the condensate is pretty high. If I run through an inboard condenser that has a pump supplying water to the shell, I can toggle it on and off for water changes in the condenser to try and keep my return to the hotwell at 140f plus.

............ Another reason I am going with the inboard condenser is I will be running on pretty cold seawater. The likelihood of getting "over cooling" of the condensate is pretty high. If I run through an inboard condenser that has a pump supplying water to the shell, I can toggle it on and off for water changes in the condenser to try and keep my return to the hotwell at 140f plus.