Page 4 of 8

Re: My column-style steamengine

Posted: Sun Oct 20, 2019 5:31 pm

by Lopez Mike

My piston valve has rings and the wear, as measured by measuring the bore, has been essentially zero. I am aware that some piston valves are fitted without rings but that seems sort of primitive.

Of course I am a heretic who thinks that plain bearings are primordial at best. I'm down to one, the big end, but that seems to be lasting well so in the spirit of deep seated sloth I'm leaving it alone.

Re: My column-style steamengine

Posted: Sun Oct 20, 2019 5:41 pm

by Lopez Mike

Dietrich,

Found a supplier here in the states. Thanks for the lead.

https://catalog.climaxmetal.com/asset/L ... mblies.pdf

Mike

Re: My column-style steamengine

Posted: Sun Oct 20, 2019 7:08 pm

by dampfspieler

Hello,

today i have tested the engine with the balanced D-valve and the new pumps. The boiler is a bit small for the job but it works. The burner is a ceramical one with a diameter of 125 mm and the normal output is 11,5 kW.

- DaMatest20191020_010kl.jpeg (123.58 KiB) Viewed 75498 times

- DaMatest20191020_011kl.jpeg (130.01 KiB) Viewed 75498 times

- DaMatest20191020_012kl.jpeg (140.89 KiB) Viewed 75498 times

Here you can see it run -

https://youtu.be/O9kkZjXPH2Y

to be continued

-Dietrich

Re: My column-style steamengine

Posted: Sun Oct 20, 2019 7:43 pm

by cyberbadger

Your attention to detail from concept to implementation is amazing.

I see what you mean about the balance, this engine is impressive aesthetically, technically, and functionally.

I wish I had detents....

-CB

Re: My column-style steamengine

Posted: Mon Oct 21, 2019 2:35 am

by TahoeSteam

Balanced slide valves reduce friction and free-up the engine. They do this by reducing surface area exposed to the force of valve chest steam pressure pushing the D-valve against valve face. Another benefit is the associated valve gear (die blocks, bushings, pins, etc) lasting longer.

Piston valves effectively have near-zero force pushing against the valve face. Essentially a "balanced" valve by nature of their construction.

I'm not sure how a piston valve would wear out any faster than a slide valve or a regular cylinder piston/wall... If the valve is vertical as in a lunch engine (gravity is in its favor!), the stem is supported by a guide that is in good order, then the only lateral forces would be from the rings on the cylinder wall (if so equipped). In theory that would require little to no lubrication if running saturated steam much like what many claim with slide valves (If supported by a proper guide, how is a piston valve much different from the piston in the cylinder???). Now if someone selected rings with too much spring to them, or port faces without any ligaments I can start to see issues... But then I would say, "Conventional slide valve-trains wear out, balanced slide valves fair much better, and poor piston valve designs wear out."

Foreign bodies on the valve face are another story altogether... With a steel boiler, one should never run a steam line without a strainer. I have some pictures of wonderfully scored valve faces if you don't believe me... On an internally lubricated engine no less.

SORRY TO HIJACK... HOPEFULLY WE CAN CONTINUE THIS DISCUSSION IN ANOTHER THREAD

Re: My column-style steamengine

Posted: Mon Oct 21, 2019 2:38 am

by TahoeSteam

Dietrich,

I am really impressed with your work. Bravo!

Re: My column-style steamengine

Posted: Tue Oct 22, 2019 1:51 am

by TahoeSteam

Did you make a different valve cover also?

Re: My column-style steamengine

Posted: Tue Oct 22, 2019 6:41 am

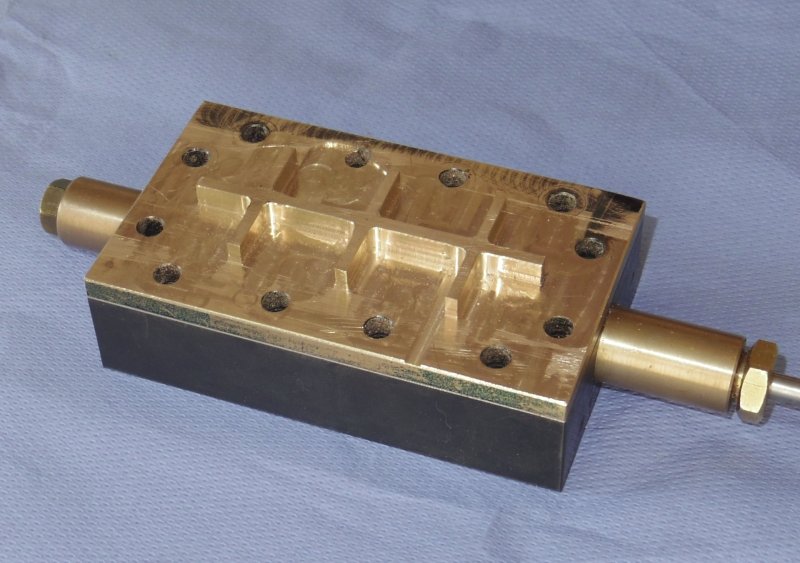

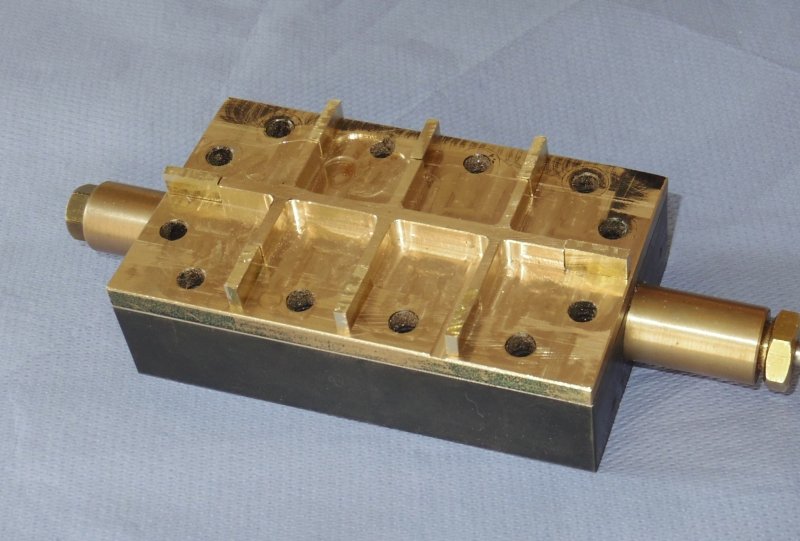

by dampfspieler

Hi Wesley,

yes and no, i have built a new from the old material. Because the old was very massive i have removed a lot of material and soldered some little parts so it looks like a casting similar to the old marine steam engine covers. Then the time was come for filing and sanding.

- EinZylBoot_SchieKa024kl.jpg (79.64 KiB) Viewed 75437 times

- EinZylBoot_SchieKa025kl.jpg (72.47 KiB) Viewed 75437 times

- EinZylBoot_SchieKa029kl.jpg (44.78 KiB) Viewed 75437 times

Then i have milled a gap at the inner side so i could mount the cup of the balanced valve. To get a smooth surface was a bit tricky.

to be continued

-Dietrich

Re: My column-style steamengine

Posted: Tue Oct 22, 2019 5:41 pm

by TahoeSteam

Such a clever solution. I really like the way it looks. You have really taken your engine to the next level.

Re: My column-style steamengine

Posted: Sun Oct 27, 2019 4:01 am

by dampfspieler

Hello,

when i've got the engine there was only a feedwater pump.

- EinZyl_Ausg010kl.JPG (50 KiB) Viewed 75351 times

Because i want to run it with condenser i had to built also a condensate pump. So there was built a new pump unit with a smaller feedwater- and a three-valve-condensate-pump at a baseplate with identical dimensions as the old one. Both pumps are picked up by the crosshead with a yoke. The piston rod and the plunger are long guided.

- PuEinh019kl.jpeg (64.05 KiB) Viewed 75351 times

to be continued

- Dietrich