Page 5 of 8

Re: My column-style steamengine - the Valves

Posted: Sun Oct 27, 2019 8:54 am

by dampfspieler

Hello,

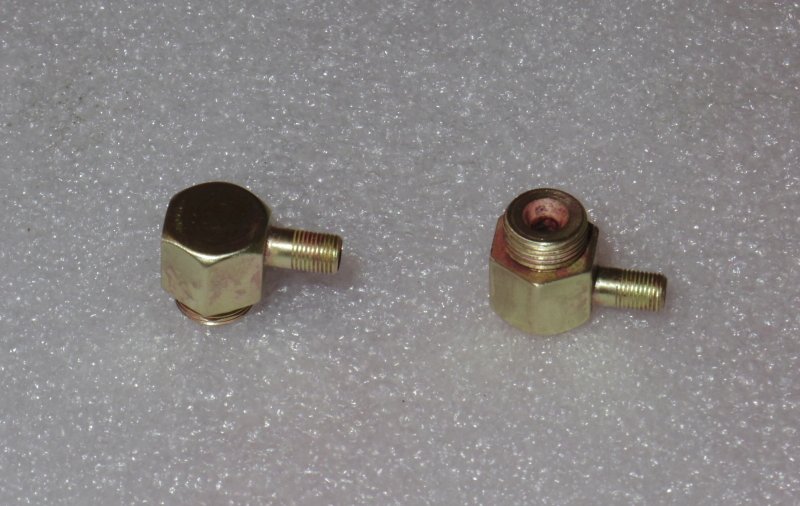

for the feedwaterpump were made two "mushroom"-valves. At speed higher than 600 rpm the ballvalves destroy the ball seats in the pump body - experience from the operation of my steam lorry MARTIN. The valves are "pressed" with very light springs to its seats so they work ut to 1.500 rpm - experience from MARTIN.

- MaSpeiPu024kl.JPG (62.94 KiB) Viewed 67520 times

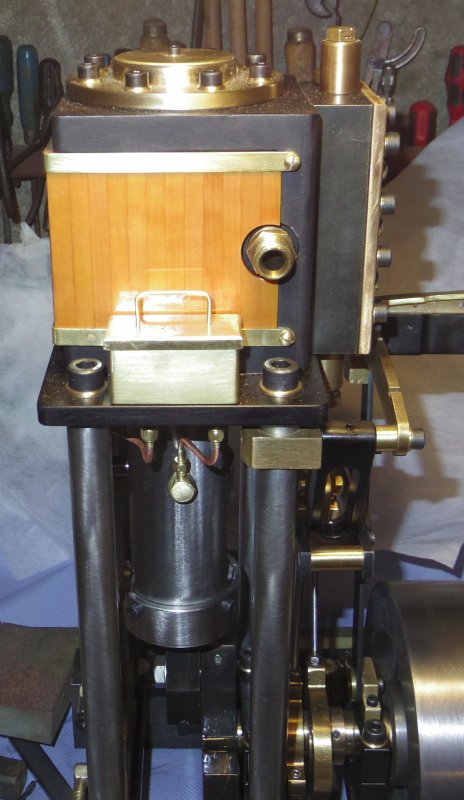

The valve chest is placed at the upper end of pump chamber to allow the air to leave the system.

The valves in the condensate pump are rubber plate types (NBR). They are small enaugh and noisy in service.

- NaLuPu041kl.jpeg (54.35 KiB) Viewed 67520 times

- NaLuPu040kl.jpeg (49.5 KiB) Viewed 67520 times

to be continued

-Dietrich

Re: My column-style steamengine

Posted: Tue Oct 29, 2019 1:06 am

by DetroiTug

Dietrich,

Good job on the check valves, I like the disc type check valves also. Ball checks are not as reliable.

-Ron

The Crosshead Guide Oiler

Posted: Sat Nov 23, 2019 9:04 am

by dampfspieler

Hello,

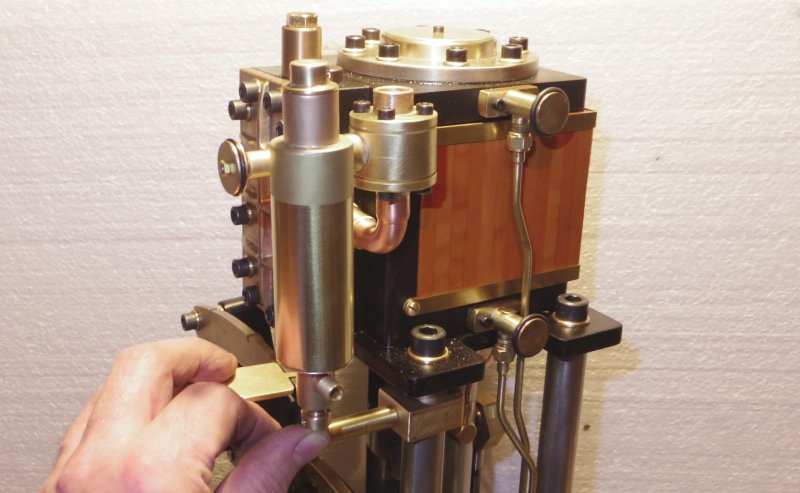

when i get the engine there was mounted a wick oiler with a cup from a solid aluminium block and plugged pipes so the oil could leak out.

- EinZyl_Ausg010kl.JPG (50 KiB) Viewed 67336 times

- EinZyl_Ausg007kl.jpeg (40.15 KiB) Viewed 67336 times

- EinZyl_Ausg008kl.jpeg (41.52 KiB) Viewed 67336 times

At my model steam lorry was a similar problem and the solution was to built a new soldered cup and screwed connections.

to be continued

-- Dietrich

Re: The Crosshead Guide Oiler

Posted: Sat Nov 23, 2019 9:27 am

by dampfspieler

Hello,

all parts were new built and silver soldered if necessary.

- GleiBaÖl003kl.jpeg (75.83 KiB) Viewed 67334 times

- GleiBaÖl008kl.jpg (56.99 KiB) Viewed 67334 times

- GleiBaÖl019kl.jpeg (67.5 KiB) Viewed 67334 times

to be continued

-- Dietrich

Re: The Crosshead Guide Oiler

Posted: Sat Nov 23, 2019 10:00 am

by dampfspieler

Hello,

the wicks were made of woolen threads.

The wicks with its handles from drilled copper wire.

- GleiBaÖl021kl.jpeg (56.25 KiB) Viewed 67330 times

The wicks in its cups (in working position).

- GleiBaÖl025kl.jpeg (83.01 KiB) Viewed 67330 times

It is easy to remove the wicks from working position and to protect the fingers from getting oily.

to be continued

-- Dietrich

The displacement lubricator

Posted: Sat Nov 23, 2019 10:35 am

by dampfspieler

Hello,

the displacement lubricator was made from bar stock and a short pipe. The regulating valve is outside of the body so it can be filled with more comfort.

The valve stem has a 20 degree tip and is tightened with an O-Ring.

- VerdrÖl_025kl.jpg (41.47 KiB) Viewed 67329 times

- VerdrÖl_080kl.jpg (58.39 KiB) Viewed 67329 times

- VerdrÖl_050kl.jpeg (67.01 KiB) Viewed 67329 times

to be continued

-- Dietrich

Re: My column-style steamengine

Posted: Sat Nov 23, 2019 4:10 pm

by RNoe

Really nice and careful work you have done.

Silver brazing is my favorite fabrication method.

RussN

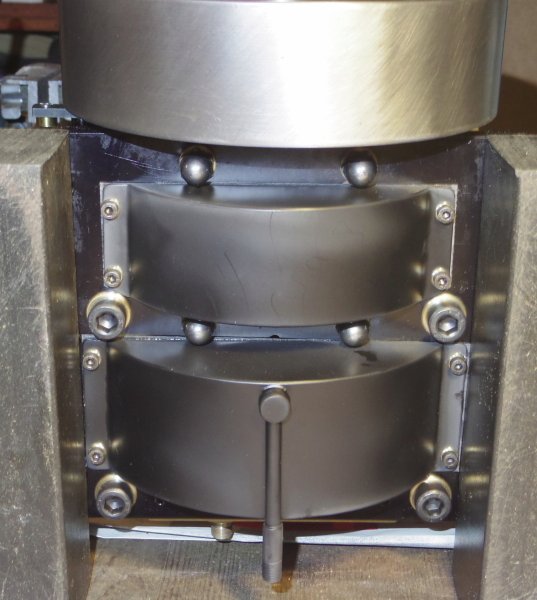

The machine trough

Posted: Sun Dec 15, 2019 10:04 pm

by dampfspieler

Hello,

because there is only a open baseplate i have built two machine troughs from brass. They were soldered in a fixture.

The fixture

- MaschWannVorr005kl.jpeg (64.07 KiB) Viewed 67134 times

- MaschWann018kl.jpeg (74.5 KiB) Viewed 67134 times

- MaschWann028kl.jpeg (52.4 KiB) Viewed 67134 times

Best

Dietrich

Re: My column-style steamengine

Posted: Tue Dec 17, 2019 6:25 pm

by fredrosse

Very nice to see such fine work. Holiday "Eye Candy" for many of us

Thanks

Re: My column-style steamengine

Posted: Tue Dec 17, 2019 7:44 pm

by TriangleTom

Beautiful work on the troughs! I look forward to reading each one of these.