Page 6 of 8

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Sun Mar 06, 2022 4:41 pm

by RNoe

Dietrich:

Very interesting ideas!

The next phase would have the stroke-adjusting disc position controlled by the boiler water level control, to automatically maintain water level...

And yes, I know there are other ways to do that, going back a century and more in time.

'Just for the mental exercise...

RussN

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Thu Mar 24, 2022 12:21 am

by dampfspieler

Russ,

... The next phase would have the stroke-adjusting disc position controlled by the boiler water level control, to automatically maintain water level...

Probably not, the mechanics should remain simple.

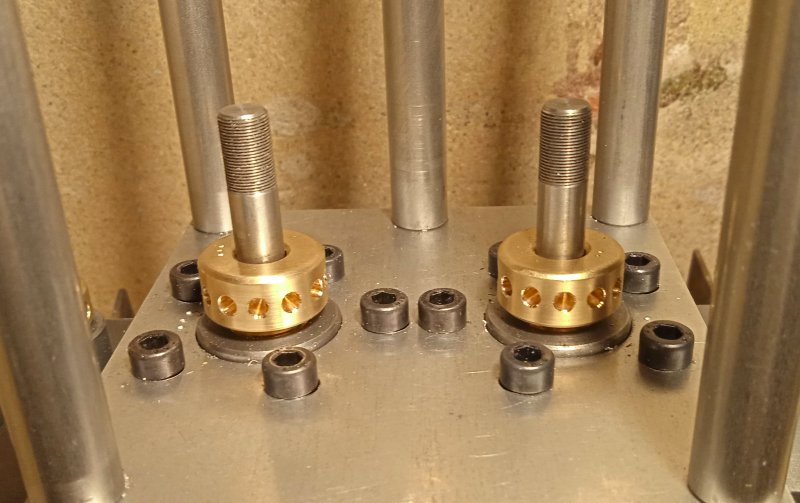

There was some little success. The piston rod gland nuts were finished so it is possible to use the spanner to tighten it with the above shown spanner.

- Twin3238_306kl.jpg (67.42 KiB) Viewed 36835 times

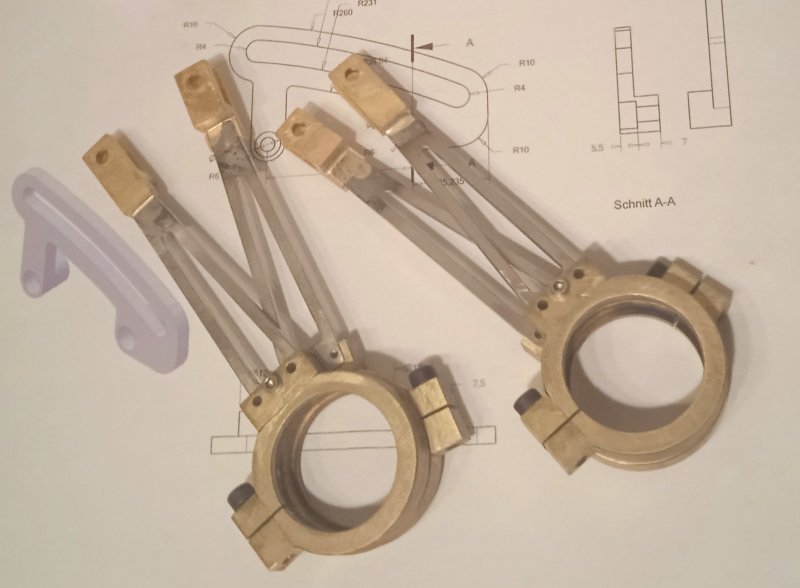

I will built the the eccentric rods from several parts.

- Twin3238_307kl.jpg (145.57 KiB) Viewed 36835 times

- Twin3238_308kl.jpg (116.86 KiB) Viewed 36835 times

--

Dietrich

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Thu Mar 24, 2022 12:26 am

by dampfspieler

The outer eccentric bodies were silver soldered.

- Twin3238_311kl.jpg (83.45 KiB) Viewed 36834 times

- Twin3238_312kl.jpg (121.9 KiB) Viewed 36834 times

Now i will mill and saw them as designed.

--

Dietrich

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Fri Mar 25, 2022 3:06 am

by DetroiTug

Good solution to save material.

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Fri Mar 25, 2022 6:02 am

by fredrosse

Additive fabrication, saves material and machining difficulties.

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Fri Mar 25, 2022 2:55 pm

by barts

On additive fabrication: Those who are not familiar with Kozo Hiraoka's excellent series in Live Steam back in the 70s and 80s would do well to examine one of his books or magazine artiles. Although somewhat smaller in scale than stuff many of us are used to, his fabrication techniques which rely extensively on fixturing and silver soldering parts together and then finish machining are well worth examining.

https://www.amazon.com/s?i=stripbooks&r ... _sr_book_1

- Bart

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Fri Mar 25, 2022 4:09 pm

by RNoe

I couldn't agree more about Kozo's books.

I have them all, have studied his multitude of techniques and built two steam locomotives so far.

And silver brazing remains one of my favorite fabrication techniques.

RussN

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Sun May 01, 2022 1:48 pm

by dampfspieler

Hi,

kozos books are one of the best i know.

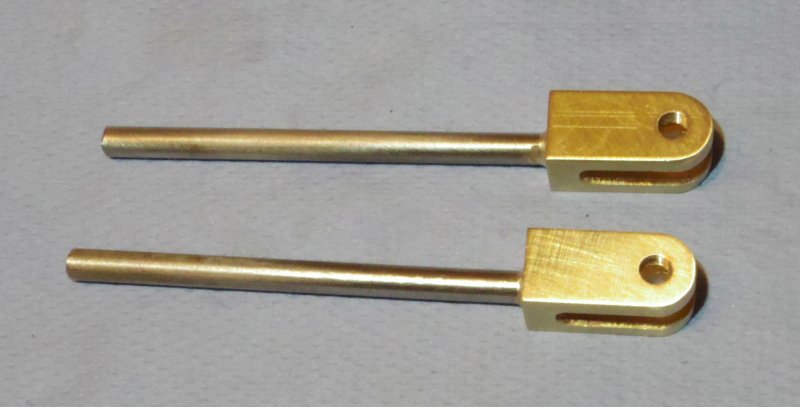

The eccentric rods are ready. It is a composite construction. The head is soldered to the middle part and that is fixed with three M3-screws to the outer eccentric bodies.

I have built a soldering fixture so all four rods will have the equal length.

- The soldering fixture

- Twin3238_366kl.jpg (64.76 KiB) Viewed 36436 times

- The soldered heads

- Twin3238_367kl.jpg (98.57 KiB) Viewed 36436 times

- The eccentric rods

- Twin3238_379kl.jpg (48.38 KiB) Viewed 36436 times

--

Dietrich

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Sun May 01, 2022 1:57 pm

by dampfspieler

Hi,

then the forks were rounded so they will look nice and go free from other parts. I had built a milling fixture and panned the parts by hand.

- The milling fixture

- Twin3238_391kl.jpg (105.83 KiB) Viewed 36435 times

Then the borings were reamed and the M5 x 0,5 mm threads cutted.

- The finished eccentric rods

- Twin3238_394kl.jpg (33.83 KiB) Viewed 36435 times

- The finished valve rods

- Twin3238_396kl.jpg (41.05 KiB) Viewed 36435 times

--

Dietrich

Re: TWIN 32 x 38 mm - steam engine for small boats or canoes

Posted: Mon May 02, 2022 5:15 am

by TahoeSteam

Dietrich,

Your work looks very good. I have to remind myself the scale that you're building at and how steady and patient you must be.

Love seeing your updates.

Cannot wait to see more