Page 1 of 1

Sealing Pistons and Valves

Posted: Thu Oct 11, 2012 8:10 pm

by jfeclipse

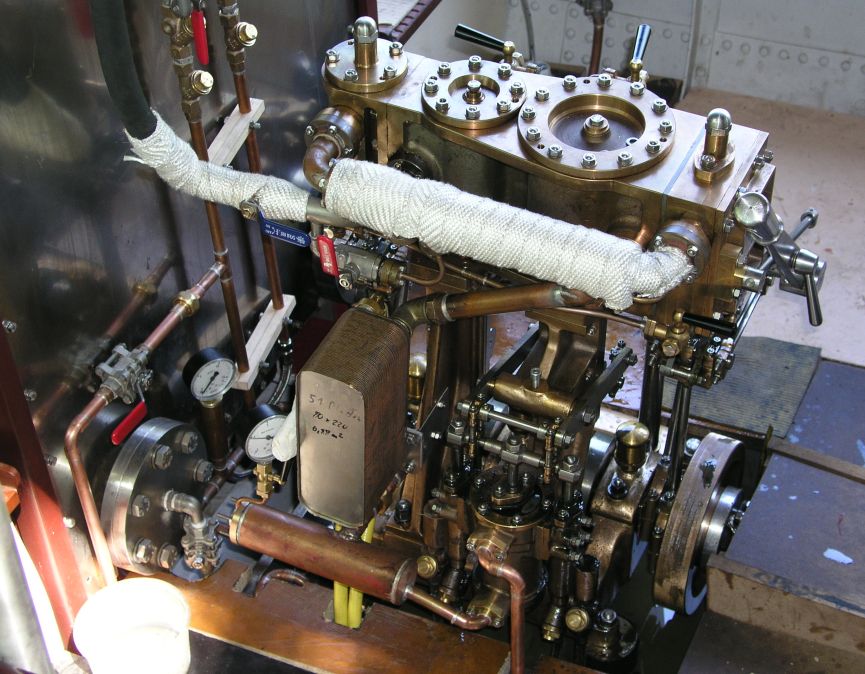

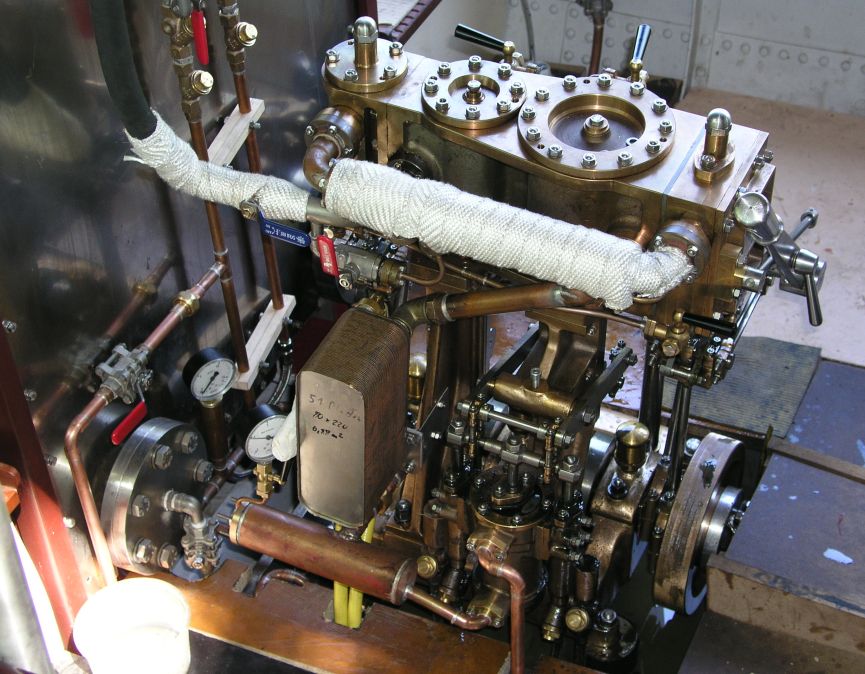

In process of checking mechanical condition of fairly large compound. During the disassembly it was noted that there was no gasket under the flanges on either top or bottom of the block. It appears there may have been a thin bead of Permatex (?) or some other sealant. There were gaskets however on the steam inlet into the HP connection. The question becomes what is accepted or "normal"?

Re: Sealing Pistons and Valves

Posted: Thu Oct 11, 2012 8:46 pm

by barts

I've used gaskets (designed for steam - Garlok) and high temp (500F) automotive silicone seal. Both worked

very well on flat smooth machined surfaces as I expected.

- Bart

Re: Sealing Pistons and Valves

Posted: Fri Oct 12, 2012 10:53 am

by Rainer

At Emma I am using O-rings at the covers because this enables you to open and close it without additional preparation before closing.

Between the valve chests and the main block I used some special high temp glue. At the HP side this blow threw. At the LP side I have a steel plate as sliding surface protecting the soft bronce block. As I tried to remove it for overhauling I hat to heat it up massively - big mess.

After all this experiences I decided to use nothing as sealant at this wide surfaces. I just screwed the clean surfaces together.

At some cold days you can see a fine steam stream coming out at one place of the HP side. But after warming the engine this will disappear. That's why it's called steam engine

I am quite happy with this solution because you have no problems to remove and reassemble all parts on the water.

Just think about if you are at a steam meet or a long jurney (lately I did a 800 km trip with Emma on German water ways) and you can't fix something because of a difficult sealing solution...

Re: Sealing Pistons and Valves

Posted: Sat Oct 13, 2012 2:29 am

by Lopez Mike

I have good luck with no gasket and just a thin film of some sort of anti seize compound such as would be used on bolts. No leaks and when I have opened things up in the field I haven't added any. I just wipe my finger about on it to make sure there is an even coat. These aren't hydraulic cylinders. My bicycle tires see almost as high a pressure.

Mike

Re: Sealing Pistons and Valves

Posted: Sun Oct 14, 2012 2:07 am

by fredrosse

Large steam turbine casings use no gaskets and typically just a thin coating of linseed oil. For steam engines I have found O-rings, seated with never-sieze, allow good disassembly with minimum work. Viton O-rings are good to about 400F - 204C, and other O-ring materials are available for other temperatures. Ordinary Rubber O-rings are ok for service up to about 250F - 120 C. If rubber O-rings are used at higher temperatures, they will seal, but disassembly can ve very troublesome as they are "cooked" in place, as Rainer stated.

Modern automotive RTV sealants seem to work well where I have used it on up to 100 PSIG - 6.9 Bar steam, although they can be a mess and are more difficult to clean surfaces as compared to a good O-ring arrangement. Automotive RTV sealants come with various temperature ratings, some much higher than 400F.

Re: Sealing Pistons and Valves

Posted: Wed Oct 17, 2012 7:20 am

by jfeclipse

Many thanks for the suggestions. Given the weight of the casting and the minimum clearances, O-rings are out of the question. Surfaces are flat so will try a high temp anti-seize such as copper coat (trade name is spelled with a "K", something like Kopr-Koat). Thanks for the inputs!