Boiler plans - Reliable Steam Engine Co

-

Sandles100

- Just Starting Out

- Posts: 7

- Joined: Wed Apr 02, 2014 9:06 am

- Boat Name: Fitting Out

- Location: Bay of Plenty, New Zealand

Boiler plans - Reliable Steam Engine Co

This might be a contentious question - I am considering purchasing plans from Reliable Steam Engine Co, for one of their Ofeldt design boilers. Can anyone comment on the standard of their design and the quality of the plans package they provide? I have read nothing adverse on these matters, but have no experience with any of their products.

She will be on the water and steaming - eventually

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Boiler plans - Reliable Steam Engine Co

I bought those plans way back when and know now that the design would produce a good boiler. Not sure how difficult it would be to get the 3/4" iron pipe wound that tightly (5" pitch diameter, which means an ID less than 4") for the coils, but they are good plans. The center drum is just off the shelf items.

A current "trend" is to weld small thimbles in where the tube would normally enter the center drum and then make coils out of copper tubing and then silver solder or braze them in to the thimbles. No special coil winding apparatus needed. I've seen a few steam car boilers like this lately. And they run in the 400 psi range with hard firing. Running it out of water would result in a lost (scorched) boiler as copper can only handle up to 406°F.

-Ron

A current "trend" is to weld small thimbles in where the tube would normally enter the center drum and then make coils out of copper tubing and then silver solder or braze them in to the thimbles. No special coil winding apparatus needed. I've seen a few steam car boilers like this lately. And they run in the 400 psi range with hard firing. Running it out of water would result in a lost (scorched) boiler as copper can only handle up to 406°F.

-Ron

- Lopez Mike

- Full Steam Ahead

- Posts: 1925

- Joined: Wed Dec 07, 2011 6:41 am

- Boat Name: S.L. Spiffy

- Location: Lopez Island, Washington State, USA

Re: Boiler plans - Reliable Steam Engine Co

And people ask me why I like VFT boilers!

A 4" I.D. coil with 3/4" steel pipe is hard to imagine. How on earth would you keep it from collapsing? And the forces involved must be really something.

I guess this shows how little I know about pipe bending. My experience has been limited to installing electrical conduit and bending soft copper up to 3/8". Not too demanding.

A 4" I.D. coil with 3/4" steel pipe is hard to imagine. How on earth would you keep it from collapsing? And the forces involved must be really something.

I guess this shows how little I know about pipe bending. My experience has been limited to installing electrical conduit and bending soft copper up to 3/8". Not too demanding.

If you think you are too small to make a difference, try sleeping with a mosquito.

Dalai Lama

Dalai Lama

-

Sandles100

- Just Starting Out

- Posts: 7

- Joined: Wed Apr 02, 2014 9:06 am

- Boat Name: Fitting Out

- Location: Bay of Plenty, New Zealand

Re: Boiler plans - Reliable Steam Engine Co

Thanks for the comments, gentlemen.

I was figuring on using the copper coils brazed into welded-on nipples. I can only envisage a 5" diam coil of 3/4 bore steel tube being successfully wound hot, and equipment/facilities for that aren't available to me. I initially considered using Cunifer10 tube, but couldn't afford the mortgage to buy the tubing! Copper's bad enough.

I'm a bit wary of VFT boilers, since in a lengthy career as a Boiler Inspector, I noted that most VFT's I checked suffered significant soft scab pitting, and it did not seem to make much difference how diligent the owners were with water treatment. I also face a bit of a challenge with weight and c.o.g. of a VFT in the hull I have.

I was figuring on using the copper coils brazed into welded-on nipples. I can only envisage a 5" diam coil of 3/4 bore steel tube being successfully wound hot, and equipment/facilities for that aren't available to me. I initially considered using Cunifer10 tube, but couldn't afford the mortgage to buy the tubing! Copper's bad enough.

I'm a bit wary of VFT boilers, since in a lengthy career as a Boiler Inspector, I noted that most VFT's I checked suffered significant soft scab pitting, and it did not seem to make much difference how diligent the owners were with water treatment. I also face a bit of a challenge with weight and c.o.g. of a VFT in the hull I have.

She will be on the water and steaming - eventually

- Lopez Mike

- Full Steam Ahead

- Posts: 1925

- Joined: Wed Dec 07, 2011 6:41 am

- Boat Name: S.L. Spiffy

- Location: Lopez Island, Washington State, USA

Re: Boiler plans - Reliable Steam Engine Co

It would be interesting to know what sort of service those pitted VFT boilers were in. And what part of the world they were in.

I took care of a 90 ton locomotive for a number of years. I was inside the boiler at least annually. It had been built in 1929 and was, of course, non-condensing and had been run from the local water sources, all soft water. Northwestern U.S.

The surfaces below the normal water line had varying amounts of calcium buildup depending on ease of access when washing down and whether the surface was original. Some of the tubes and flues had been replaced since new. The surfaces beneath the calcium were smooth.

Above the normal waterline the original mill scale from the manufacturing of the plate was mostly still intact.

On some of the outside surfaces where painting had been lax, there was some pitting.

The usual pros and cons apply as you mention. Some are choices such as whether a larger mass of water is desired. Low C.G. is a good thing though if I were building a new boiler for my boat I would be looking carefully at a locomotive type such as a scotch.

The VFT is slower to react both in operation and at fireup. It takes my VFT 30 with wood firing a half of an hour to get up to pressure from cold. And when coming to the dock it takes some foresight to avoid popping the safety. On the other hand, I can be pretty much a dolt as to feeding the fire and still keep going.

I took care of a 90 ton locomotive for a number of years. I was inside the boiler at least annually. It had been built in 1929 and was, of course, non-condensing and had been run from the local water sources, all soft water. Northwestern U.S.

The surfaces below the normal water line had varying amounts of calcium buildup depending on ease of access when washing down and whether the surface was original. Some of the tubes and flues had been replaced since new. The surfaces beneath the calcium were smooth.

Above the normal waterline the original mill scale from the manufacturing of the plate was mostly still intact.

On some of the outside surfaces where painting had been lax, there was some pitting.

The usual pros and cons apply as you mention. Some are choices such as whether a larger mass of water is desired. Low C.G. is a good thing though if I were building a new boiler for my boat I would be looking carefully at a locomotive type such as a scotch.

The VFT is slower to react both in operation and at fireup. It takes my VFT 30 with wood firing a half of an hour to get up to pressure from cold. And when coming to the dock it takes some foresight to avoid popping the safety. On the other hand, I can be pretty much a dolt as to feeding the fire and still keep going.

If you think you are too small to make a difference, try sleeping with a mosquito.

Dalai Lama

Dalai Lama

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Boiler plans - Reliable Steam Engine Co

I haven't noticed any rusting in my VFT, but I blow down hot and leave it open to dry out. I never leave water in it. I use no water treatment and pump straight out of whatever river or lake I'm in. Going on 5 years and all is well.

RE: Ofeldt in a boat. They are great boilers and I think it is the best all around design ever concocted, but I'm not sure I'd want one in a boat for hand-firing. They have a very small volume and they are a bit of a hotrod in the steam generator realm. They can make lots of steam in a hurry. They also go through lots of water in a hurry and they are very responsive to the heat of the fire. The fireman would be very busy with no water automatics and solid fuel firing. The big VFT in the Tug I can literally let it go for 15 minutes at a time without adding wood or flipping any valves. With an Ofeldt, simply opening the firebox would probably be noticeable. Also it is important to only impinge fire on the coils only - the center drum acts as a downcomer to maintain internal circulation. Some sort of heat deflector should be used on the bottom of the center drum for wood firing or use an Ofeldt kerosene burner that is essentially a ring of fire on the coils only. I can attest that the OFeldt boiler and burner are very good. Making steam in as little as one minute once the burner has ignited, in the video below this was firing up from cold. This car has an Ofeldt boiler and kerosene burner.

Thinking back after I posted above:

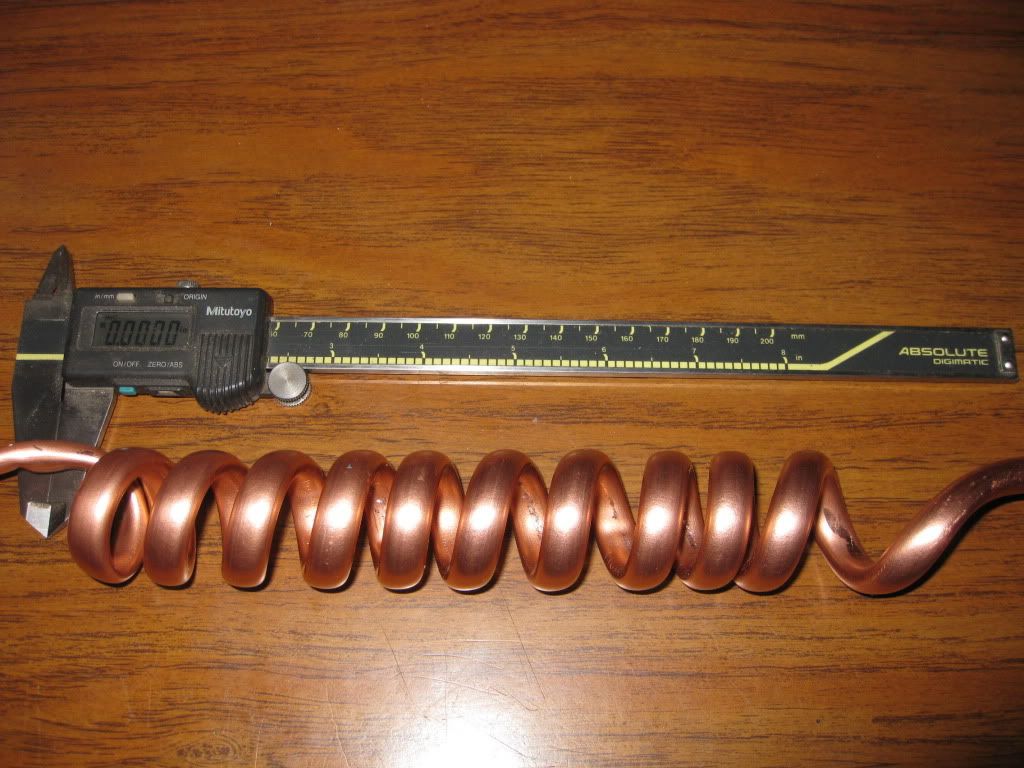

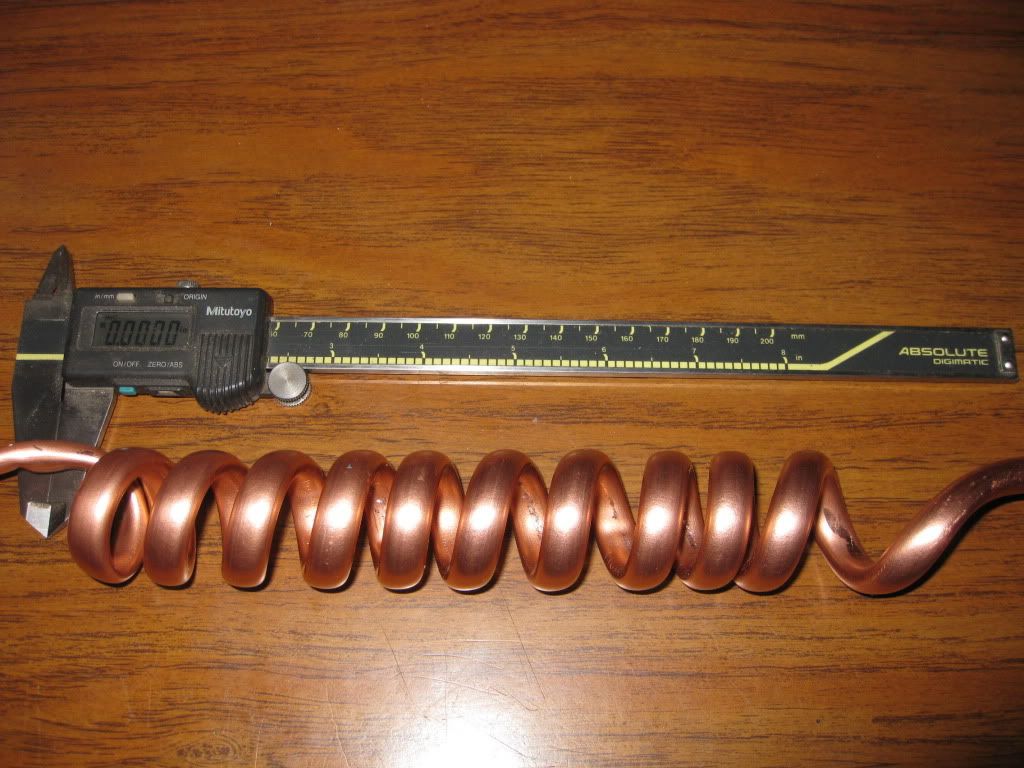

When I had my coils wound for the Ofeldt which are schedule 40 1/4" A53 steel pipe, the man that wound them for me said he could do up to 3/4" Schedule 160 on the same mandrel which is 4" in diameter. The mandrel was just a piece of barstock. The machine was a homemade beast of giant roller chains and massive wormgear right-angle drive. It wound the 1/4" without even hesitating. So, it can be done.

Copper tubing. If it is filled tightly with silica sand and then the ends folded over, it can literally be tied in a knot without kinking. I wound this piece of 3/8" K copper on a 3/4" mandrel.

-Ron

RE: Ofeldt in a boat. They are great boilers and I think it is the best all around design ever concocted, but I'm not sure I'd want one in a boat for hand-firing. They have a very small volume and they are a bit of a hotrod in the steam generator realm. They can make lots of steam in a hurry. They also go through lots of water in a hurry and they are very responsive to the heat of the fire. The fireman would be very busy with no water automatics and solid fuel firing. The big VFT in the Tug I can literally let it go for 15 minutes at a time without adding wood or flipping any valves. With an Ofeldt, simply opening the firebox would probably be noticeable. Also it is important to only impinge fire on the coils only - the center drum acts as a downcomer to maintain internal circulation. Some sort of heat deflector should be used on the bottom of the center drum for wood firing or use an Ofeldt kerosene burner that is essentially a ring of fire on the coils only. I can attest that the OFeldt boiler and burner are very good. Making steam in as little as one minute once the burner has ignited, in the video below this was firing up from cold. This car has an Ofeldt boiler and kerosene burner.

Thinking back after I posted above:

When I had my coils wound for the Ofeldt which are schedule 40 1/4" A53 steel pipe, the man that wound them for me said he could do up to 3/4" Schedule 160 on the same mandrel which is 4" in diameter. The mandrel was just a piece of barstock. The machine was a homemade beast of giant roller chains and massive wormgear right-angle drive. It wound the 1/4" without even hesitating. So, it can be done.

Copper tubing. If it is filled tightly with silica sand and then the ends folded over, it can literally be tied in a knot without kinking. I wound this piece of 3/8" K copper on a 3/4" mandrel.

-Ron

- Lopez Mike

- Full Steam Ahead

- Posts: 1925

- Joined: Wed Dec 07, 2011 6:41 am

- Boat Name: S.L. Spiffy

- Location: Lopez Island, Washington State, USA

Re: Boiler plans - Reliable Steam Engine Co

Ron,

I an so impressed by those bends. I have very little experience with bending and most of it has been no so good.

I hadn't even thought of steaming an Oldfeldt with solid fuel. Not a happy combination. I think if I was going to have a boiler that was rather volatile I would have the burner automated to react to steam pressure. Since I am not very bullish about automation beyond a hot well float, that takes car of that.

I an so impressed by those bends. I have very little experience with bending and most of it has been no so good.

I hadn't even thought of steaming an Oldfeldt with solid fuel. Not a happy combination. I think if I was going to have a boiler that was rather volatile I would have the burner automated to react to steam pressure. Since I am not very bullish about automation beyond a hot well float, that takes car of that.

If you think you are too small to make a difference, try sleeping with a mosquito.

Dalai Lama

Dalai Lama

-

Sandles100

- Just Starting Out

- Posts: 7

- Joined: Wed Apr 02, 2014 9:06 am

- Boat Name: Fitting Out

- Location: Bay of Plenty, New Zealand

Re: Boiler plans - Reliable Steam Engine Co

Hey thanks for the comments and advice people, I really appreciate it. Manufacture of an Ofeldt design is significantly cheaper for me, since I am not a "code" welder (my welding looks like seagull poop), and I want the boiler to be as near to a local code as I can get it while still using copper tube for coils. My plan is to use steam atomised liquid fuel, with LPG for light up (and chuck a lump of coal into the furnace now & then just to impress the onlookers with the smoke and smell!). I'm looking also at basic fuel flow control working off boiler pressure - nothing electric. I'm steam trained and biased against anything invisible which lives in a copper wire or battery.

Regarding problems with pitting on VFT tubes - it was mostly evident in newer boilers, although on looking back over my survey notes, I only had 2 VFT's which were over 30 years old. These where in very good condition, and averaged near on 2000 hours per year. Both were Nat Gas fired, having been converted from liquid fuel. I had a couple of locomotives on my list. One was looked after by a young man with wild eyes and long hair, who always appeared to be over-medicating on funny pills. His boiler was in beautiful condition. He treated it with Tannin and nothing else aprt from loving care. The other was looked after by a committee of very sober ex-railwaymen. It was near junk, regularly leaked on test and looked awful inside. I reckon boiler water treatment is probably a branch of witchcraft.

Regarding problems with pitting on VFT tubes - it was mostly evident in newer boilers, although on looking back over my survey notes, I only had 2 VFT's which were over 30 years old. These where in very good condition, and averaged near on 2000 hours per year. Both were Nat Gas fired, having been converted from liquid fuel. I had a couple of locomotives on my list. One was looked after by a young man with wild eyes and long hair, who always appeared to be over-medicating on funny pills. His boiler was in beautiful condition. He treated it with Tannin and nothing else aprt from loving care. The other was looked after by a committee of very sober ex-railwaymen. It was near junk, regularly leaked on test and looked awful inside. I reckon boiler water treatment is probably a branch of witchcraft.

She will be on the water and steaming - eventually

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Boiler plans - Reliable Steam Engine Co

"nothing electric. I'm steam trained and biased against anything invisible which lives in a copper wire or battery" Proper attitude in my view. In fact, while most of the world uses electricity and magnetism very much, they still don't really know what it actually is. Many of the very knowledgable technical people fear the day when electronic artifical intellegence might become reality. That day may actually come soon, and might spell the end of humanity.

For the old Star Trek fans, remember the "prime directive", that was to not interfere with the natural order of things, be they considered good or bad. Artifical intellegence should have that feature programmed in, but by definition artifical intellegence might decide on its own that humans just destroy too much of the resources, or are a threat to something considered all important, and should be eliminated, or enslaved, or whatever. Enter the Matrix, or the Terminator, or...?

Apologies for the off topic rant.

For the old Star Trek fans, remember the "prime directive", that was to not interfere with the natural order of things, be they considered good or bad. Artifical intellegence should have that feature programmed in, but by definition artifical intellegence might decide on its own that humans just destroy too much of the resources, or are a threat to something considered all important, and should be eliminated, or enslaved, or whatever. Enter the Matrix, or the Terminator, or...?

Apologies for the off topic rant.

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Boiler plans - Reliable Steam Engine Co

"artificial intelligence"

I've been employing it for years, it's nothing to fear...

" I'm looking also at basic fuel flow control working off boiler pressure"

That is the best route and there are many non-electric ways to do that. Have a look at some of the steam car fuel regulators. Simply a diaphragm controlling a valve - open under low pressure - closed or low flame under high pressure.

The Ofeldt Kerosene burner I'm using for the car uses no electricity. But it requires a Kerosene fuel tank under pressure ( 50 psi) for the main burner. And a small pressurized (15 psi) pilot tank with white gas. Kerosene can be used for both, but the pilots will need to be cleaned more often. I use to Optmus Nova all fuel backpacker stoves for the pilot lights. There is a thread on this forum about it. The drawback for steamboating (for me) is it would be pretty loud in a hull as are many of these types of burners. Some are not bad though, do some research.

http://www.thesteamboatingforum.net/for ... f=8&t=1444

Although, few steamboaters want to, sometimes electric accessories are simply vital. I have some electric stuff on the tug. The Spotlight - no oil or carbide light is going to compare with it. A 12 volt pump for filling the boiler at launch - I'm not pumping 40 gallons of water with a 1" bore by 2" stroke hand pump. Interior lights - these are two fold, easier to use and much brighter, plus they add safety, an oil lantern can fall and start a fire. For running water for a sink, on demand pumps are necessary. Otherwise it would require a pressurized holding tank which is a bit of a pain to deal with. Dismiss steam pumps and steam powered anything for overnight stays aboard. The time under steam is actually quite small compared to the time in the water. Nobody wants to build a head of steam just to use a sink. I use a 12v deep cycle marine battery and then there is a small permanent magnet generator on the engine to replenish the battery. An easy route to a burner is a converted to 12volt home oil furnace "gun burner". They use a lot of current and will drain a battery in short order. Essentially relegating the whole plant comparable to something electric powered that needs to be plugged in and charged up at shut down. Or when it goes dead. And they are loud.

-Ron

I've been employing it for years, it's nothing to fear...

" I'm looking also at basic fuel flow control working off boiler pressure"

That is the best route and there are many non-electric ways to do that. Have a look at some of the steam car fuel regulators. Simply a diaphragm controlling a valve - open under low pressure - closed or low flame under high pressure.

The Ofeldt Kerosene burner I'm using for the car uses no electricity. But it requires a Kerosene fuel tank under pressure ( 50 psi) for the main burner. And a small pressurized (15 psi) pilot tank with white gas. Kerosene can be used for both, but the pilots will need to be cleaned more often. I use to Optmus Nova all fuel backpacker stoves for the pilot lights. There is a thread on this forum about it. The drawback for steamboating (for me) is it would be pretty loud in a hull as are many of these types of burners. Some are not bad though, do some research.

http://www.thesteamboatingforum.net/for ... f=8&t=1444

Although, few steamboaters want to, sometimes electric accessories are simply vital. I have some electric stuff on the tug. The Spotlight - no oil or carbide light is going to compare with it. A 12 volt pump for filling the boiler at launch - I'm not pumping 40 gallons of water with a 1" bore by 2" stroke hand pump. Interior lights - these are two fold, easier to use and much brighter, plus they add safety, an oil lantern can fall and start a fire. For running water for a sink, on demand pumps are necessary. Otherwise it would require a pressurized holding tank which is a bit of a pain to deal with. Dismiss steam pumps and steam powered anything for overnight stays aboard. The time under steam is actually quite small compared to the time in the water. Nobody wants to build a head of steam just to use a sink. I use a 12v deep cycle marine battery and then there is a small permanent magnet generator on the engine to replenish the battery. An easy route to a burner is a converted to 12volt home oil furnace "gun burner". They use a lot of current and will drain a battery in short order. Essentially relegating the whole plant comparable to something electric powered that needs to be plugged in and charged up at shut down. Or when it goes dead. And they are loud.

-Ron