Two weeks ago, I've spotted on a Craig's-List-like site a gizmo sold as a "bronze priming pump" and priced 32.90 € (shipment included). Like any decent pump, it had a very nice lever. But it was a whistle, not a pump! So I bought it.

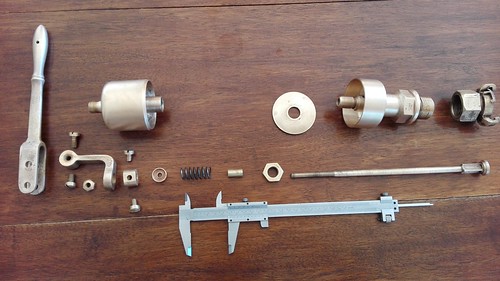

I gave it an over night pickle bath and a thorough cleaning. Here are a bunch of photos of the beast with a 30 cm caliper (the open jaws are 5 cm appart):

-> The exploded view:

-> The maker's mark:

-> The assembled whistle:

The maker's mark is not clear. I can't read for sure the first letter stamped on the lower bell. I guess it's "DELOULE", in Lyon, France. I found a society called DELOULE wich was in business in Lyon between the 2 WW, they mainly manufactured pumps.

The eagle eye among you may have notice that:

1. On the exploded pic, the lever was turned upside down and there is no gasket at all.

2. There's a compressed air nipple that fits the base of the whistle. => This is NOT a steam whistle. We'll discuss this point later.

3. The valve stem is scored, not toot badly but enough to leak air/steam when the whistle is blown.

4. The parts attaching the lever to the valve stem are not meant to work without creating a small bend. In fact, the second nut from the top has a hole larger than the stem to prevent the bend but it's not very effective.

-> This whistle is intended to be blown with compressed air. I want to use it on my future boat. I have a few ideas but I need your advice.

Regards,

Christophe