Hello again

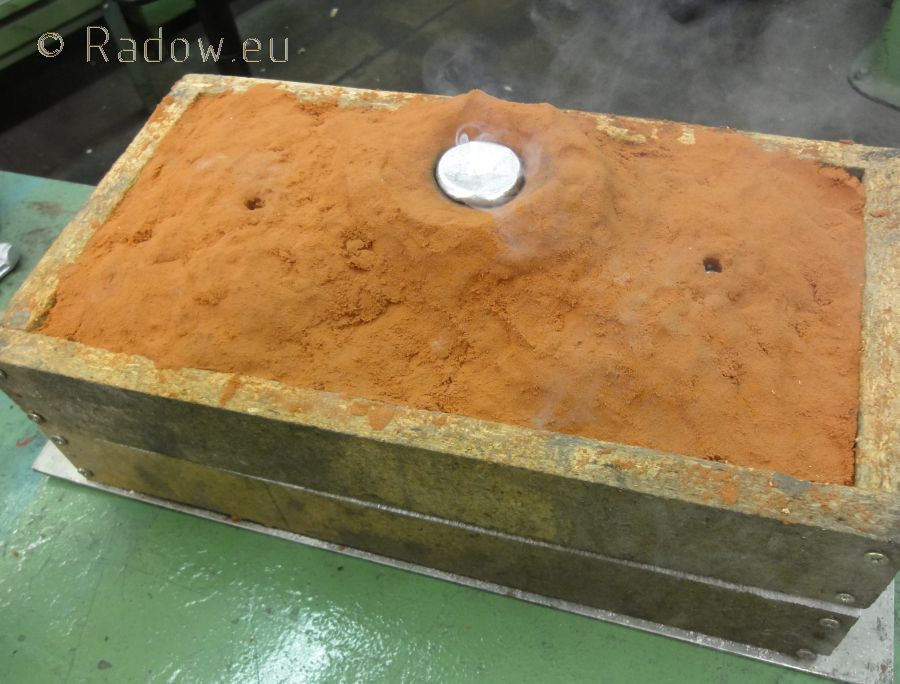

This weekend I focus on making the pattern for the combined LP piston and valve crosshead guide.

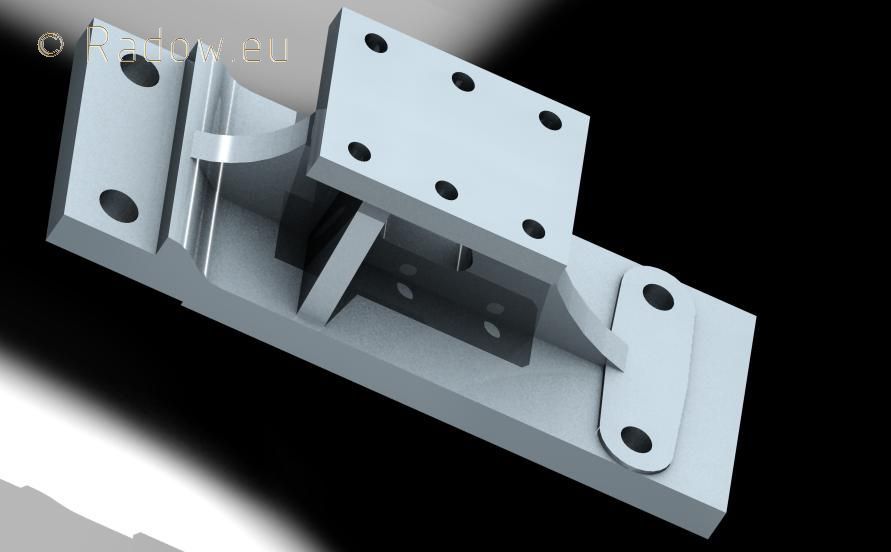

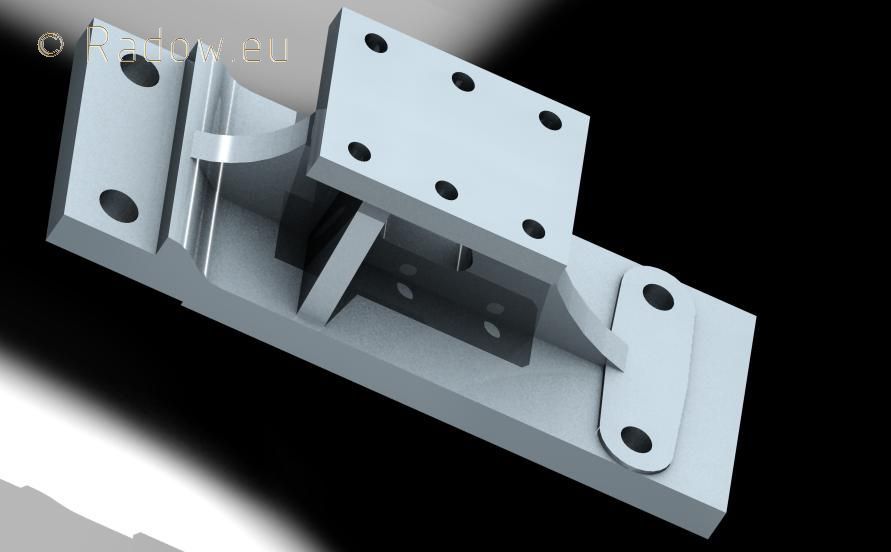

In this view of the sub assembly "d21-nd-gleitbahn-zb" you can get an imagination of its purpose. (Nuts are size M6 and M8)

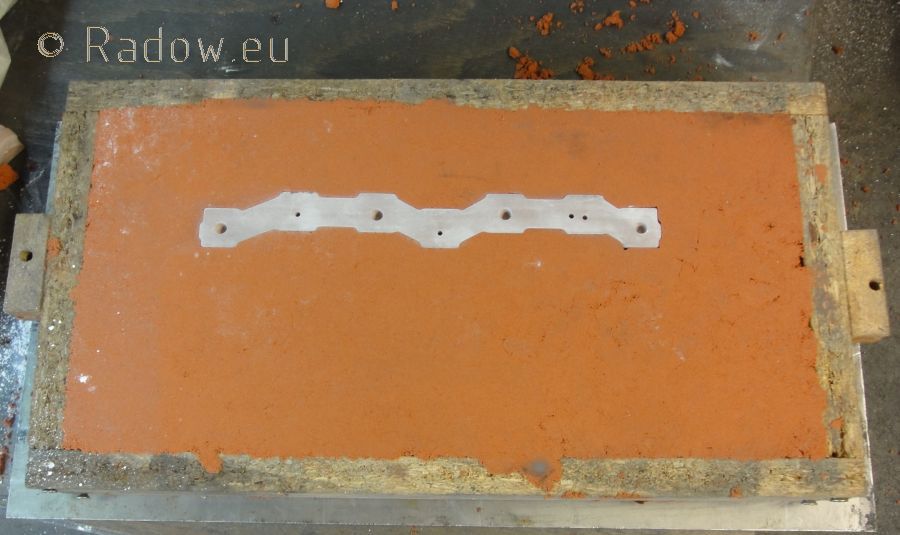

The next photo shows the isolated part "d21-nd-gleitbahn". For the use in the basic CAD model it has no fancy round shapes and lifting bevels. This is to keep the model small and the answering time of the system short. But on todays home computers and such a small model this is not the main reason. Such a simple structure makes it much easier to change basic design issues during all layout phases.

After determining the functions and geometric relations and matching all connecting surfaces, screw holes etc. it is easy to make the pattern from it.

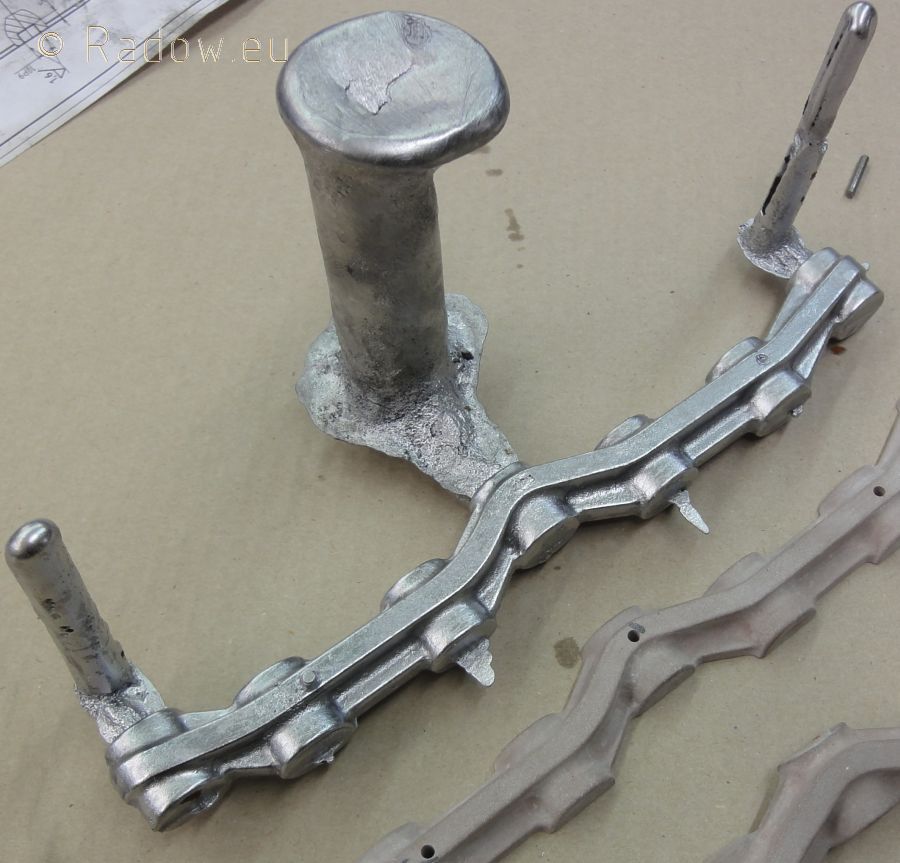

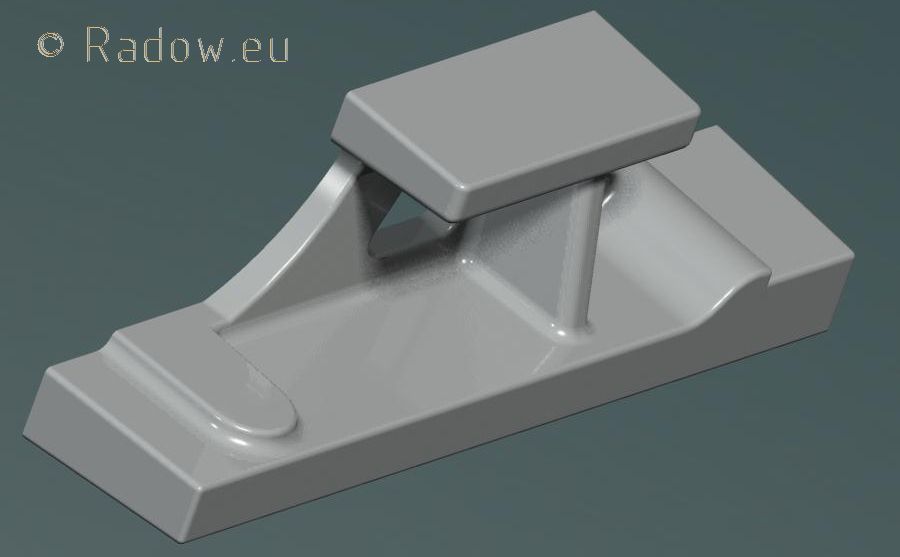

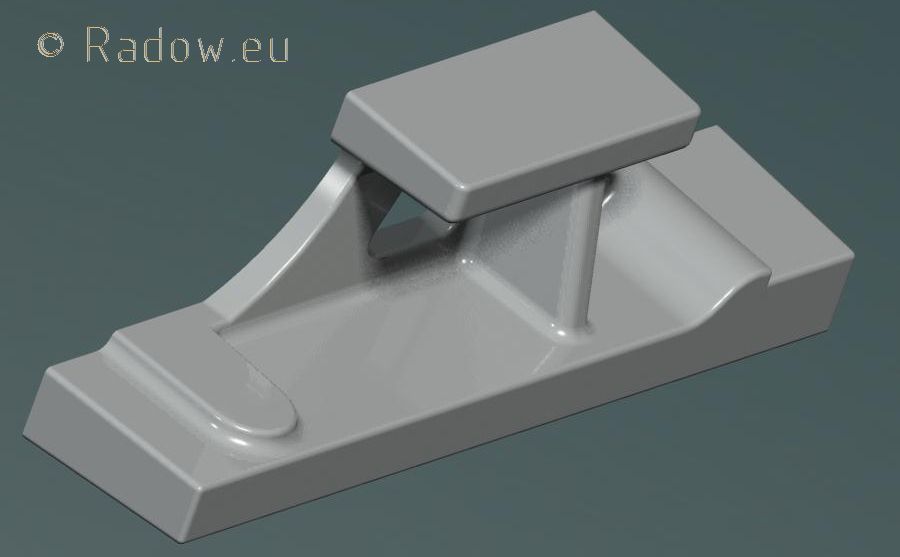

The base of this pattern "d21-modell" is still the part "d21-nd-gleitbahn". First I cut away one half. Then I "glued" on some 3 mm machining allowance where necessary. Next I changed the surface angles to good lifting bevels of 1°, 2°, 3° or even 5° on small edges. Finally I broke the sharp edges with a radius of 1, 2 or 2.5 mm - 2.5 mm because I will use a 5 mm ball nose cutter.

I did it in exactly this sequence because it is the easiest operation to make a half cut of a part but the most "exciting" task to get nice and closed round coutures around the part.

My file "d21-modell" now consists of a link to "d21-nd-gleitbahn" and the description of the operations of cutting, gluing and shaping - but not of the basic geometry.

When someone now decides to change the slide way width for example, I have to do this in the base model "d21-nd-gleitbahn". After that this changes went into the "d21-modell" and automatically changes it - if I am lucky. Sometimes after this operation you have to redesign some lifting bevels etc. because of the change of the basic structure and the impossibility of the derived geometry.

The advantage of this method is that after changes in the concept you mostly have a still stable base design of the steam engine. You only have to correct things in individual files with "standalone" parts.