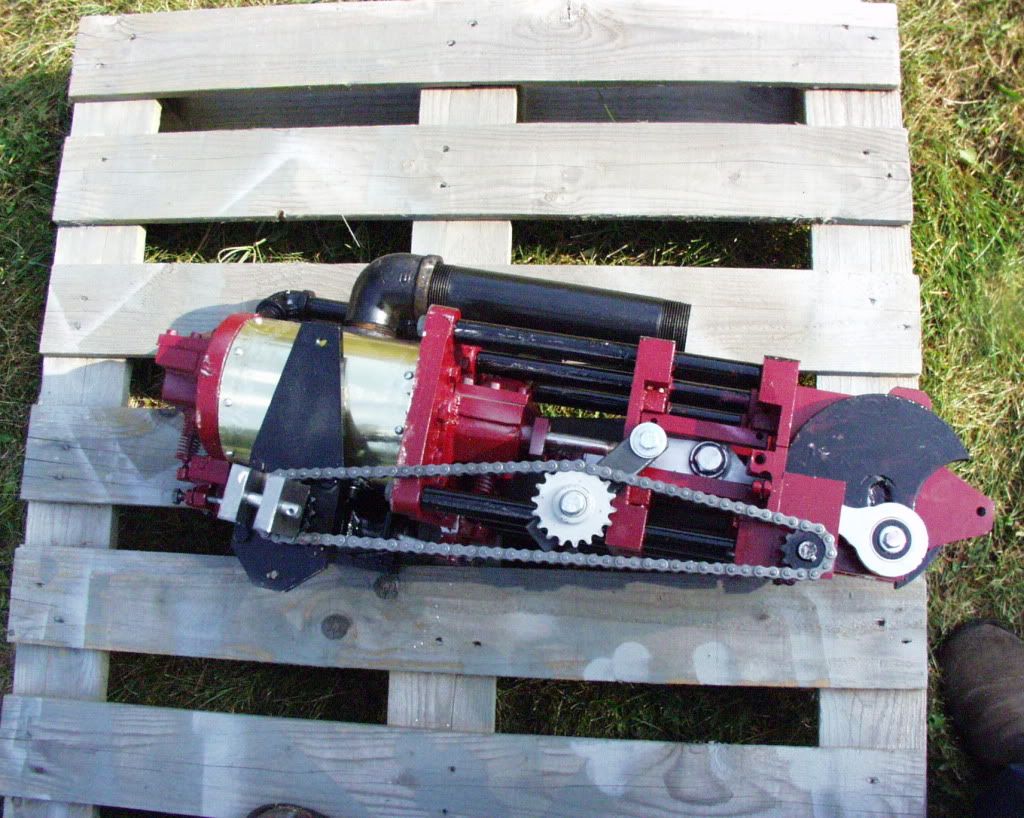

As a result, I'm looking at the following:

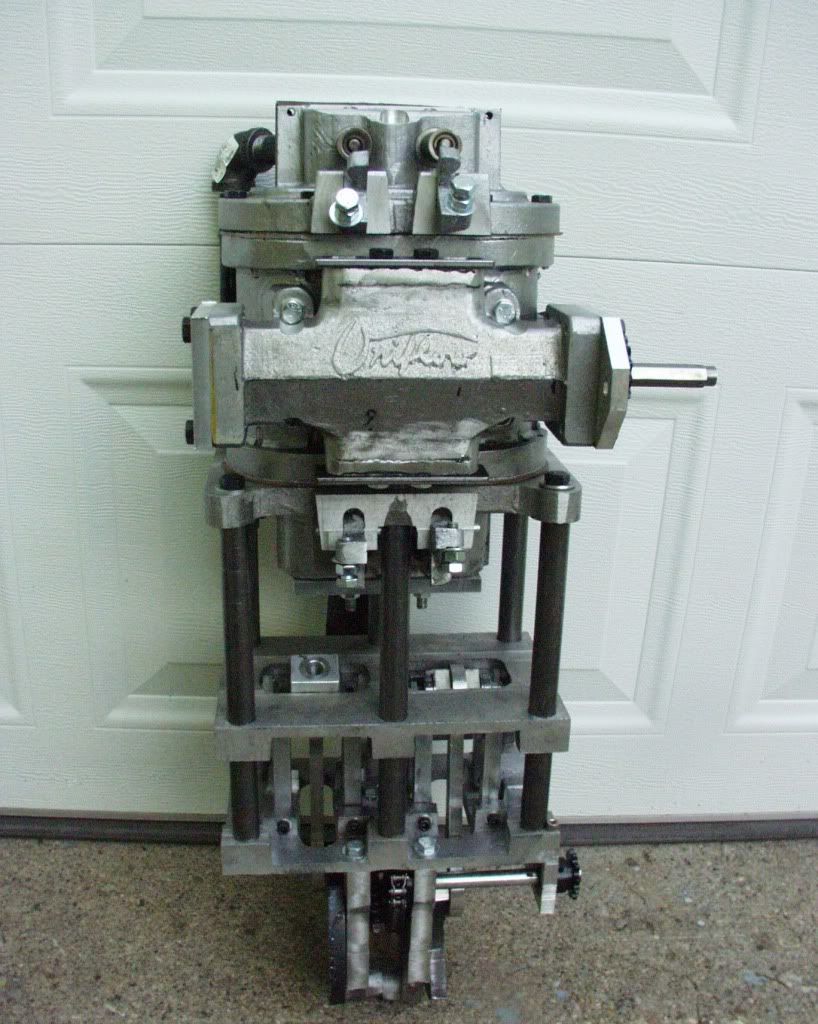

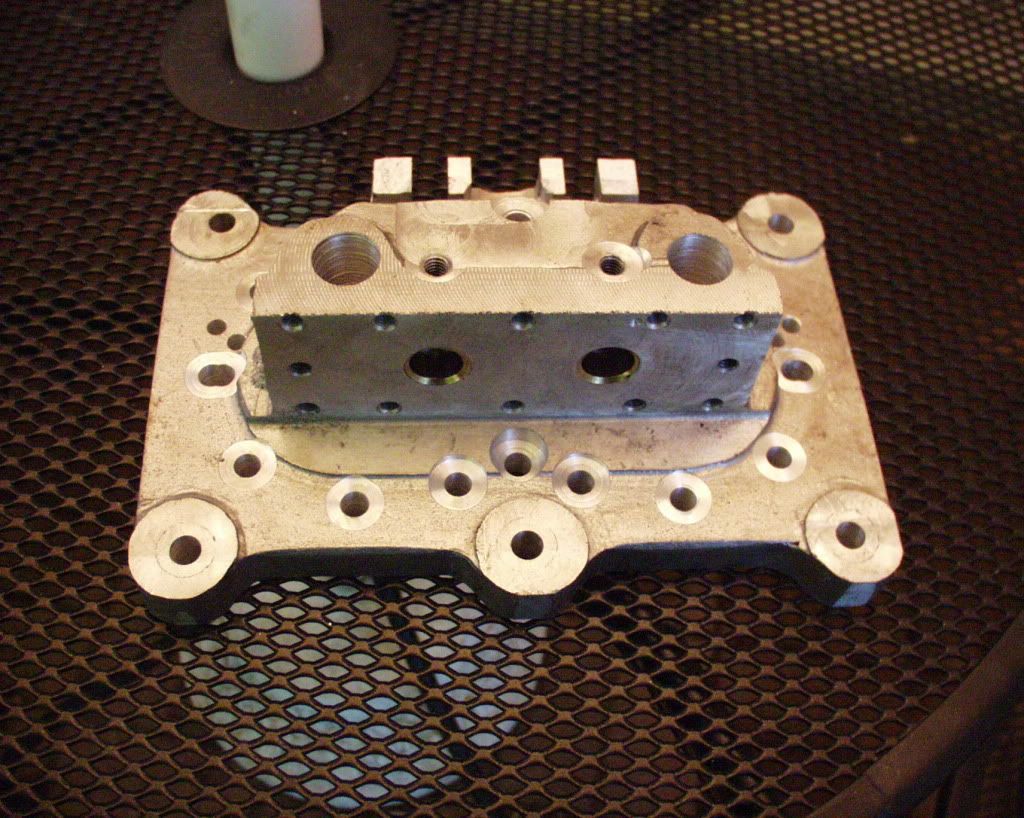

* twin cylinder inline double acting simple uniflow; cylinders are

cut-down Detroit Die*l 53 CID liners. Steam powered vacuum eductor

for ease of starting. 3.875" bore x 4.25" stroke, jacketed head, entire

cylinder well insulated. Built-up hollow piston to cut down on weight.

* poppet valves configured so that excessive cylinder pressure

will lift them; very low clearance volume (2 %).

* Operating pressure 200-300 psi, 600 F steam temperature.

* variable cut-off from 2.5 % to 10%, w/ a bump for starting...

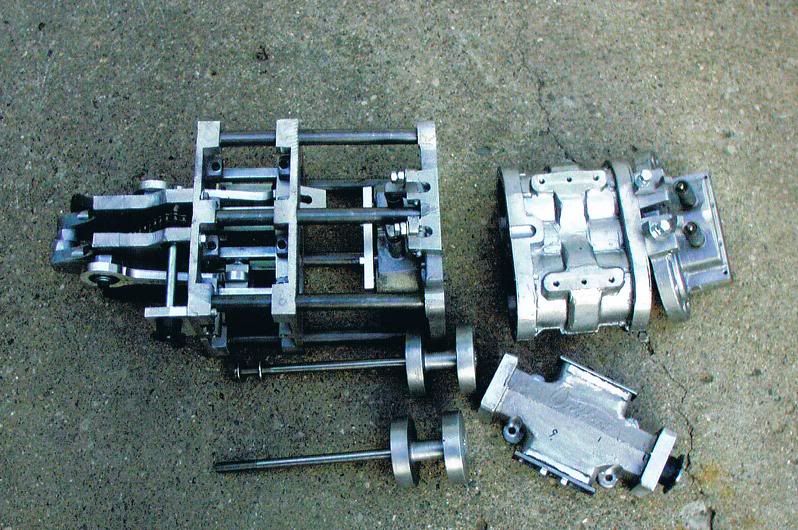

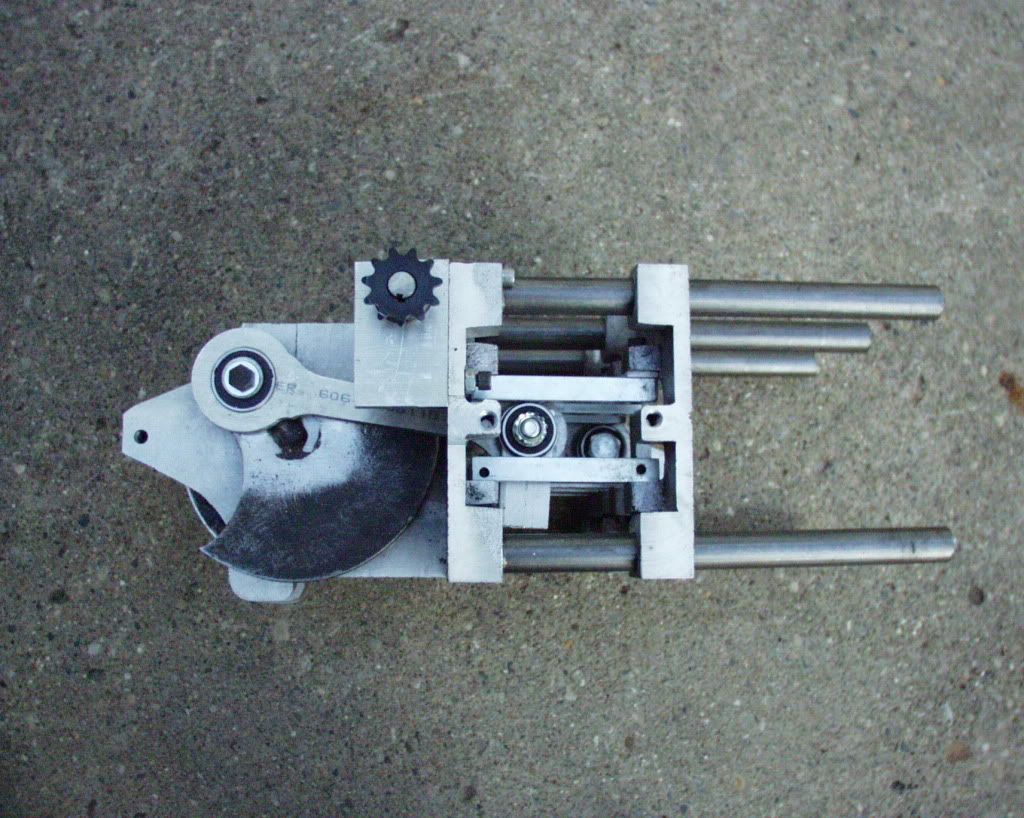

Since the engine is in the cabin, I'm considering a roller crosshead to

cut down on the hot oil smell; perhaps I should finder a better smelling

oil

the crank will be built up w/ a pinch bolt design ala Rolly Evans' designs. I'm considering

pressure lubrication of the mains and crankpins (via drilled passages); I'd likely include

scavenging passages as well to help cut down on oil flying about. The wrist pin

bearings will be greased needle bearings.

For valve gear, I'm inclined to go with Skinner's dual cam setup so that valve

timing is completely variable; two shifting cams would be simpler but offer

limited adjustment and are operationally less sure.

Calculations suggest 6 - 19 IHP over with 35 - 150 lbs/hr steam consumption;

actual HP realized is likely 2/3s of these values.

So far, it appears this design can be made to work as a series of machined weldments

and chucks of cast iron.

- Bart