Thrust bearing assembly

- marinesteam

- Full Steam Ahead

- Posts: 313

- Joined: Thu Nov 19, 2009 2:51 am

- Boat Name: Idris

- Location: Colorado USA

Thrust bearing assembly

The thrust bearing that is specified for the York engine is no longer available and in the process of sourcing a suitable replacement it got me thinking about the assembly as a whole. I'd like to get some more thoughts on thrust bearings.

The York compound has an integrated thrust bearing assembly. In its current form, the forward thrust from the prop shaft is transferred to the bedplate through a ball, thrust bearing. The reverse thrust is transferred through a plain bronze bearing. The plain bearing and hub also serves to keep the thrust bearing from coming apart as it and the ball thrust bearing sandwich on each side of the part that attaches to the bedplate. The end of the crankshaft is a keyed sliding fit into the hub.

It seems to me that there should be no reason that the plain bearing couldn't be replaced with a tapered roller bearing.The reasoning that roller bearings would be less likely to be noisy and have less sensitivity to poor lubrication. I have found bearings that fit into the same space envelope as the originally specified thrust bearing and plain bearing. The originally specified ball thrust bearing would remain essentially the same with only slight dimensional differences and the plain bearing would be replaced by the tapered roller bearing. The ball thrust bearing does have a slight improvement in the load capacity over the original and is much better than the tapered roller bearing. The tapered bearing really is only needed to hold the assembly together and for less often seen reversing forces. The tapered bearing is rated for over 17,000lbs dynamic force.

Thoughts?

Thanks

Ken

The York compound has an integrated thrust bearing assembly. In its current form, the forward thrust from the prop shaft is transferred to the bedplate through a ball, thrust bearing. The reverse thrust is transferred through a plain bronze bearing. The plain bearing and hub also serves to keep the thrust bearing from coming apart as it and the ball thrust bearing sandwich on each side of the part that attaches to the bedplate. The end of the crankshaft is a keyed sliding fit into the hub.

It seems to me that there should be no reason that the plain bearing couldn't be replaced with a tapered roller bearing.The reasoning that roller bearings would be less likely to be noisy and have less sensitivity to poor lubrication. I have found bearings that fit into the same space envelope as the originally specified thrust bearing and plain bearing. The originally specified ball thrust bearing would remain essentially the same with only slight dimensional differences and the plain bearing would be replaced by the tapered roller bearing. The ball thrust bearing does have a slight improvement in the load capacity over the original and is much better than the tapered roller bearing. The tapered bearing really is only needed to hold the assembly together and for less often seen reversing forces. The tapered bearing is rated for over 17,000lbs dynamic force.

Thoughts?

Thanks

Ken

-

Cyruscosmo

- Full Steam Ahead

- Posts: 117

- Joined: Mon Sep 23, 2013 11:56 pm

- Boat Name: No Boat Yet

- Location: Woodinville

Re: Thrust bearing assembly

My two cents is, go with a tapered roller set. The trucks I do the maintenance work on have tapered rollers and some of them have over a hundred thousand on the same set. Then there are the drivers who seem to hit everything on the road and only get sixty or so thousand out of a set. There is a reason they switched from ball bearings to tapered roller bearings for axles! Ball bearings are a lot more picky about the preload. Get it right and they are happy, get it wrong and they go away pretty quick.

In my experience a tapered roller set will take a lot more abuse than a ball bearing will.

A roller bearing will be quieter than a ball thrust bearing but you will still need to make sure it has a good seal. With the right seal and a bit of grease you will likely never have to mess with it again... like... ever!

Anyway I am going with a set for the trust bearings on my engine as well as rollers for the rod journals and mains. Don't get me wrong, I like plain bearings too but I am building this boat for fun and blowing my whistle for the purdy girls sounds like a lot more fun than fiddling with an oilcan!

Cheers,

Scott

In my experience a tapered roller set will take a lot more abuse than a ball bearing will.

A roller bearing will be quieter than a ball thrust bearing but you will still need to make sure it has a good seal. With the right seal and a bit of grease you will likely never have to mess with it again... like... ever!

Anyway I am going with a set for the trust bearings on my engine as well as rollers for the rod journals and mains. Don't get me wrong, I like plain bearings too but I am building this boat for fun and blowing my whistle for the purdy girls sounds like a lot more fun than fiddling with an oilcan!

Cheers,

Scott

My Grandpa told me when I was 8 or so that “You have to learn by the mistakes of others! Because you will NOT live long enough to make them all yourself.” At that age I though I had forever to learn everything...

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Thrust bearing assembly

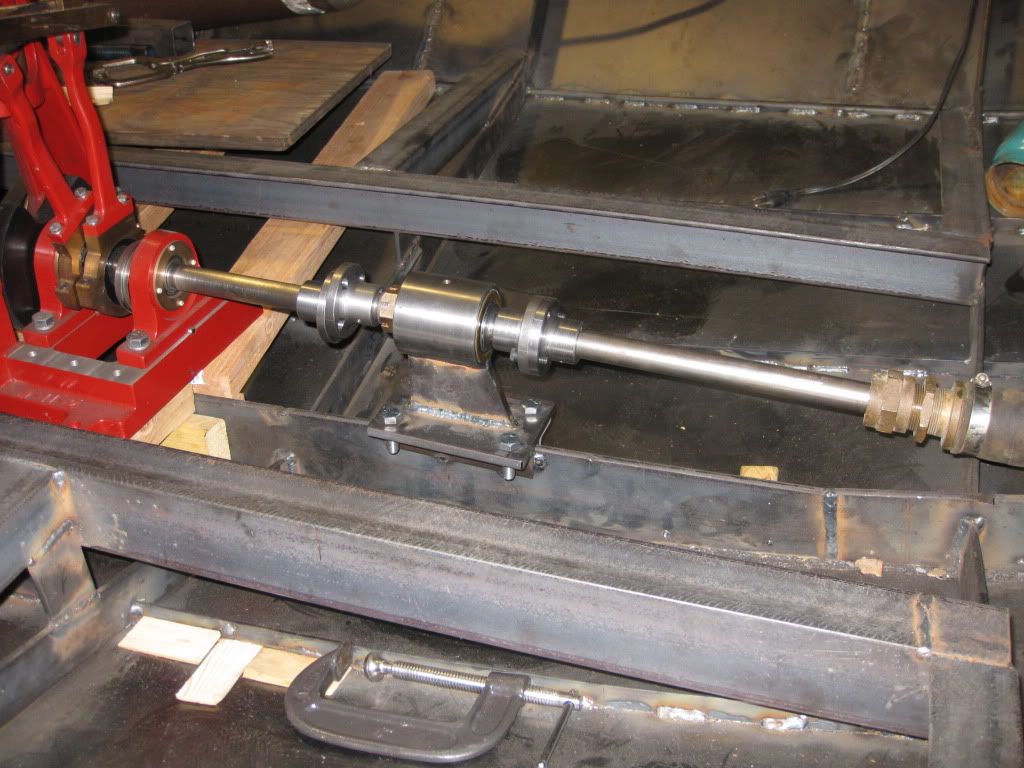

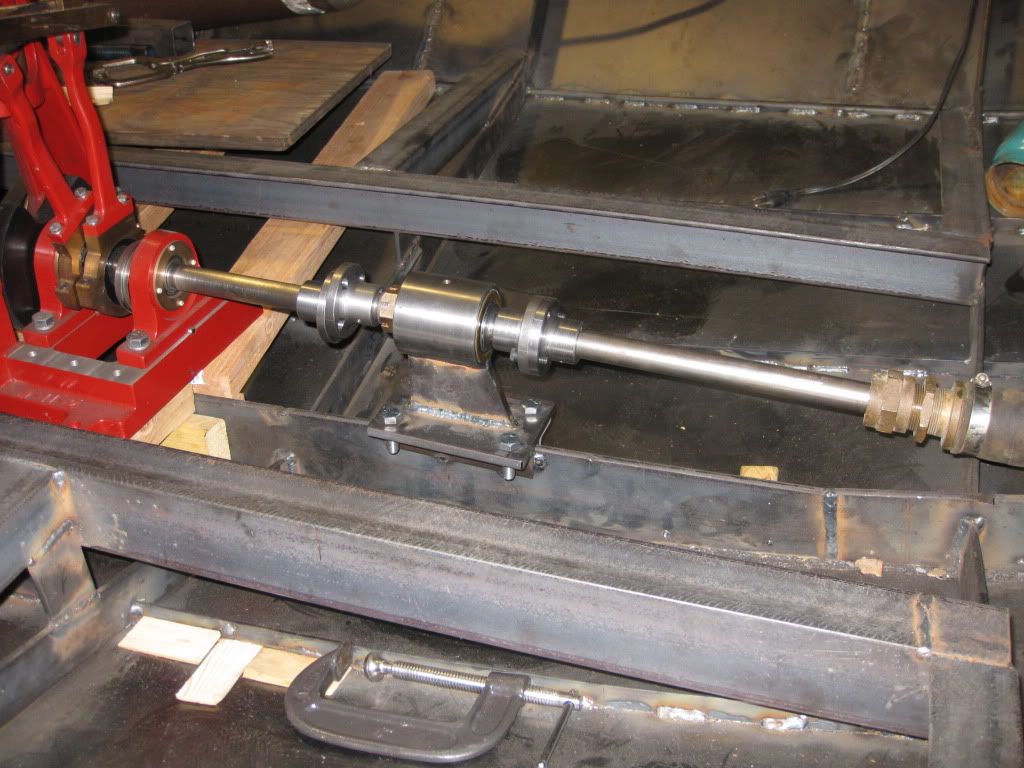

I used tapered bearings in the thrust block. Standard boat trailer bearings and seals- easily sourced in remote locations. The bronze nut has one of the sealing surfaces on it. As Scott mentions above, tapered bearings are very durable and low maintenance. This unit was installed, greased and has worked flawlessly.

-Ron

-Ron

- fredrosse

- Full Steam Ahead

- Posts: 1925

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Thrust bearing assembly

I agree with all that is stated above. Automotive (or trailer) tapered roller bearings are far more duty worthy than ball bearings, and that is why they have ended up on every truck, car, and trailer found on the highway.

The propeller thrust forces on our launches range up to a few hundred pounds, for example a 20 horsepower boat at 9 knots gives a nominal thrust of under 600 pounds, and not many of us have such a powerful and fast launch. The thrust loads on my boat trailer (or on an automobile) are easily that high just going around a corner in normal driving. Tapered roller beatings are the way to go for a large safety factor.

Standard ball bearings are certainly OK for most all steam launch thrust bearings, and they often come with a spherical seat, so they are self aligning, which is a good feature for some of us who do not have excellent machine alignment skills.

The propeller thrust forces on our launches range up to a few hundred pounds, for example a 20 horsepower boat at 9 knots gives a nominal thrust of under 600 pounds, and not many of us have such a powerful and fast launch. The thrust loads on my boat trailer (or on an automobile) are easily that high just going around a corner in normal driving. Tapered roller beatings are the way to go for a large safety factor.

Standard ball bearings are certainly OK for most all steam launch thrust bearings, and they often come with a spherical seat, so they are self aligning, which is a good feature for some of us who do not have excellent machine alignment skills.

-

Cyruscosmo

- Full Steam Ahead

- Posts: 117

- Joined: Mon Sep 23, 2013 11:56 pm

- Boat Name: No Boat Yet

- Location: Woodinville

Re: Thrust bearing assembly

Hey Don

I like that design, mind if I borrow it and make one for my boat? Also I was looking at the picture of your installation and was wondering how you dealt with a propeller jam situation?

I had in mind making a flange like I see in your picture between the thrust bearing and the engine. The rear flange would have a pilot shaft that extended inside the forward flange but instead of bolts it would have a sheer pin. That way if the prop picked up a rope, net, log or whatever fate throws my way it would sheer the pin and not the shaft.

it would sheer the pin and not the shaft.

Any thoughts?

Cheers

Scott

I like that design, mind if I borrow it and make one for my boat? Also I was looking at the picture of your installation and was wondering how you dealt with a propeller jam situation?

I had in mind making a flange like I see in your picture between the thrust bearing and the engine. The rear flange would have a pilot shaft that extended inside the forward flange but instead of bolts it would have a sheer pin. That way if the prop picked up a rope, net, log or whatever fate throws my way

Any thoughts?

Cheers

Scott

My Grandpa told me when I was 8 or so that “You have to learn by the mistakes of others! Because you will NOT live long enough to make them all yourself.” At that age I though I had forever to learn everything...

- marinesteam

- Full Steam Ahead

- Posts: 313

- Joined: Thu Nov 19, 2009 2:51 am

- Boat Name: Idris

- Location: Colorado USA

Re: Thrust bearing assembly

Thanks Gentlemen,

My intent is to replace the ball thrust bearing with another in an available size, A tapered roller bearing will be substituted for the plain bearing, as I have just enough space in the existing casting to do so, just not enough for two tapered bearings, however. I never thought of adding a seal, thanks for the tip.

Ken

My intent is to replace the ball thrust bearing with another in an available size, A tapered roller bearing will be substituted for the plain bearing, as I have just enough space in the existing casting to do so, just not enough for two tapered bearings, however. I never thought of adding a seal, thanks for the tip.

Ken

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Thrust bearing assembly

I don't mind a bitCyruscosmo wrote:I like that design, mind if I borrow it and make one for my boat?

Cyruscosmo wrote:Also I was looking at the picture of your installation and was wondering how you dealt with a propeller jam situation?

I had in mind making a flange like I see in your picture between the thrust bearing and the engine. The rear flange would have a pilot shaft that extended inside the forward flange but instead of bolts it would have a sheer pin. That way if the prop picked up a rope, net, log or whatever fate throws my wayit would sheer the pin and not the shaft.

I've not had to deal with that and I don't think it would be that big of an issue as the engine at the pressures I run is simply not all that powerful. If there were a failure from the inertia, I would think it would shear the bolts off in the coupler. Maybe I'm lucky or careful? But in all the years of running inboards, Other than the blasted lake grass we have here now, I've only damaged one prop and that was on some rocks in murky water, where I should not have been. Nothing broke loose on that, the ol' Chevy smallblock in the Chris Craft wound the beautiful bronze prop in to Xmas tree ornament. Luckily the Monel shaft was ok.

For the lake grass here that we continually encounter. When I mounted the prop I purposely put it close to the strut to chop the grass up and clear it. Seems to work pretty good. Can always tell when the prop grabs a big clump of it, the engine slows slightly and barks a little louder in the stack.

-Ron

-

Cyruscosmo

- Full Steam Ahead

- Posts: 117

- Joined: Mon Sep 23, 2013 11:56 pm

- Boat Name: No Boat Yet

- Location: Woodinville

Re: Thrust bearing assembly

Hey Ron

It may not ever happen but since I am going to make the flange and trust bearing I may as well make it a “fusible link” so to speak. I have seen a lot of flotsam in the sound that I would not want tangled in my prop. On the ferry to Bremerton from Seattle I caught sight of a log that would ruin any boats day. And just about any stretch of beach around here has a good selection of driftwood occupying the high tide line.

Cheers

Scott

It may not ever happen but since I am going to make the flange and trust bearing I may as well make it a “fusible link” so to speak. I have seen a lot of flotsam in the sound that I would not want tangled in my prop. On the ferry to Bremerton from Seattle I caught sight of a log that would ruin any boats day. And just about any stretch of beach around here has a good selection of driftwood occupying the high tide line.

Cheers

Scott

My Grandpa told me when I was 8 or so that “You have to learn by the mistakes of others! Because you will NOT live long enough to make them all yourself.” At that age I though I had forever to learn everything...

- DetroiTug

- Full Steam Ahead

- Posts: 1863

- Joined: Fri Nov 27, 2009 5:56 pm

- Boat Name: Iron Chief

- Location: Northwest Detroit

Re: Thrust bearing assembly

Yeah we don't get too many stray "floatables" here in the inland waters. But I do know what you're talking about. I was on a big reservoir once that was at unusually high water, there were logs everywhere.

Another advantage to a set up like you're suggesting is to have the ability to disengage the prop shaft. That way feedpumps can be ran dockside. With the Tug and it's steel hull I just let it nose up on the bank and let it run.

-Ron

Another advantage to a set up like you're suggesting is to have the ability to disengage the prop shaft. That way feedpumps can be ran dockside. With the Tug and it's steel hull I just let it nose up on the bank and let it run.

-Ron

-

Cyruscosmo

- Full Steam Ahead

- Posts: 117

- Joined: Mon Sep 23, 2013 11:56 pm

- Boat Name: No Boat Yet

- Location: Woodinville

Re: Thrust bearing assembly

Feed pumps!  Yeah I knew that! LOL!

Yeah I knew that! LOL!

Ok... actually I had not thought of that, but that is a damn good idea. I will write that down here in the necessary accessories section. So along with a sacrificial pin I could include a dog clutch and just pop it out of drive to idle at the docks.

It might be fun to install a big water pump and sport a fire cannon on deck too! I could really get their attention during the Hydro races with a rooster tale of my own!

And I could use it to fend off pirates.

Cheers

Scott

Ok... actually I had not thought of that, but that is a damn good idea. I will write that down here in the necessary accessories section. So along with a sacrificial pin I could include a dog clutch and just pop it out of drive to idle at the docks.

It might be fun to install a big water pump and sport a fire cannon on deck too! I could really get their attention during the Hydro races with a rooster tale of my own!

And I could use it to fend off pirates.

Cheers

Scott

My Grandpa told me when I was 8 or so that “You have to learn by the mistakes of others! Because you will NOT live long enough to make them all yourself.” At that age I though I had forever to learn everything...