Page 11 of 16

Re: And Now for the Twin

Posted: Mon Dec 21, 2020 5:06 pm

by Mike Rometer

Hi Guys, yes, I've been missing again. It's that domesticity thing, someone has to do it.

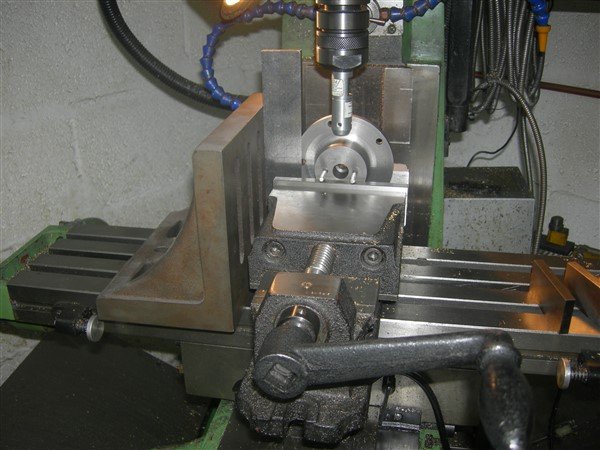

This next bit has had me thinking. A lot! I struggled to think of an accurate way to set it up, however as with a lot of things, get started, and it will clear the fog.

The job is cutting the bedding pad on the bottom covers for the slide bars, I have a laser centre finder but don't trust it totally, it seems to fit differently every time, and setting up is as painful as resetting the miller head to zero, so not undertaken lightly. It also isn't wonderful on curved surfaces (might be my cataracts). The first part is to set up the cover in the machine vice. Large angle plate and a parallel to get the cover vertical.

- Cyl Cover (29) (600 x 450).jpg (62.96 KiB) Viewed 17387 times

Next to find the extremities, I got round the curved surface by setting a short parallel against it and using its corner, zeroed the DRO, then transferred to the other side, and used the 1/2 function to get centre. (I actually did it several times to be sure).

- Cyl Cover (31) (600 x 450).jpg (43.7 KiB) Viewed 17387 times

Set the depth, and fire up.

- Cyl Cover (36) (600 x 450).jpg (62.01 KiB) Viewed 17387 times

Result!

Side two another day.

Re: And Now for the Twin

Posted: Mon Dec 21, 2020 6:41 pm

by RNoe

Mike R said: "I have a laser centre finder but don't trust it totally, it seems to fit differently every time..."

When using a laser center finder, I found it needed to be rotating during use.

That eliminated any angular errors.

Maybe that's normal usage, but I've never gotten "lessons" on proper use of those tools.

And perhaps commercial grade laser center finders are totally accurate while stationary.

I don't have a commercial grade laser center finder...

RussN

Re: And Now for the Twin

Posted: Mon Dec 21, 2020 7:38 pm

by Mike Rometer

RNoe wrote: ↑Mon Dec 21, 2020 6:41 pm

Mike R said: "I have a laser centre finder but don't trust it totally, it seems to fit differently every time..."

When using a laser center finder, I found it needed to be rotating during use.

That eliminated any angular errors.

Maybe that's normal usage, but I've never gotten "lessons" on proper use of those tools.

And perhaps commercial grade laser center finders are totally accurate while stationary.

I don't have a commercial grade laser center finder...

RussN

Exactly what I do, find the offset in whichever direction suits, then mark and rotate 180 and go again. A lot easier than trying to centralise it.

Re: And Now for the Twin

Posted: Mon Dec 21, 2020 9:15 pm

by DetroiTug

Any reference device needs to be spun to average errors associated with it's mounting and collet runout.

The inexpensive laser devices are a sad joke to the machinist, about as accurate as eyeballing. Yes, machining centers use them,but they are a far more precision laser.

Get one of these, an edge finder, pick up one side of your cylindrical object, zero out, move across, pick up the other side, then divide by 2. That is the center.

Re: And Now for the Twin

Posted: Mon Dec 21, 2020 10:48 pm

by DetroiTug

For indicating center of bores, holes, outer diameters, I use an Indicol/interapid combination. Any machine shop you go in, the edgefinder and the indicol and interapid or some close variant of it are the two mainstay referencing implements. I've seen so many machinists try those laser devices and after inaccuracies causing the spoil of a few workpieces, it gets tossed.

The indicol is also used to sweep ground standards after boat stoning the table to align the head ninety degrees to the work surface. Or 'tramming' the mill. Can also surf angle plates to check their ninety degree accuracy and parallelism to z axis. Lots of uses. Those two are the mainstay.

Re: And Now for the Twin

Posted: Wed Dec 23, 2020 4:29 pm

by Mike Rometer

I term those 'Finger Clocks', and do use them when I need.

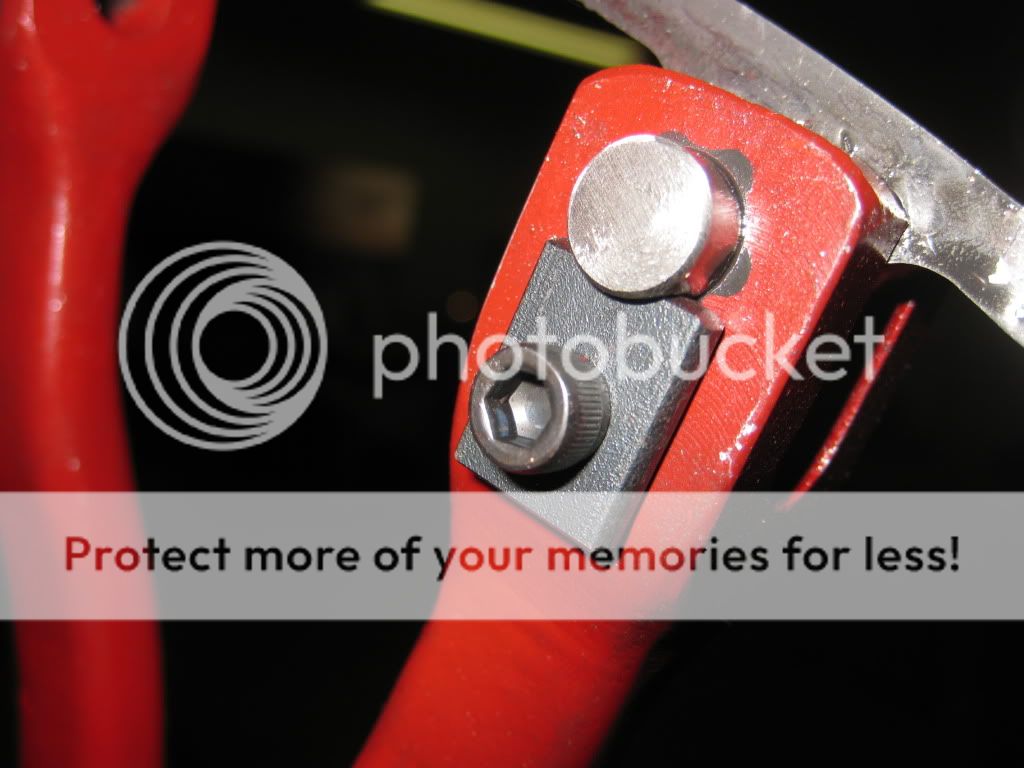

Today I cut the other slide-bar pad, and drilled and tapped the mounting holes. I'm not particularly a fan of socket head bolts on steam engines but this time they seemed to suit the purpose rather than the look, and they were 'to hand'.

- Cyl Cover (33) (600 x 450).jpg (63.9 KiB) Viewed 17335 times

Re: And Now for the Twin

Posted: Wed Dec 30, 2020 6:14 pm

by Mike Rometer

I have not been idle! (Someone had to wear the red coat and white beard!)

I've made up the cyl. mounting plates. I roughed them in the shaper then finished off in the mill with a fly cutter.

- Cyl Mount (2) (600 x 450).jpg (58.67 KiB) Viewed 17259 times

- Cyl Mount (4) (600 x 450).jpg (72.34 KiB) Viewed 17259 times

The next bit brings a small dilemma. I need to sort out which method for fixing the cross-heads to the piston rods is most suitable. They could be just inserted into a reamed hole and taper cross-pinned. They could be tapped and threaded, or they could be tapered and cross-pinned. The trickiest is the tapered and pinned as it's more difficult to get the length exact, a few extra thou off and it goes considerably deeper. Perhaps I'm just too fussy?

Re: And Now for the Twin

Posted: Wed Dec 30, 2020 7:33 pm

by Lopez Mike

Maybe do the tapered crosshead end first. The piston end can then be machined as near right as you can measure and then be adjusted, if needed, by either taking a bit more off of the shoulder that is against the bottom of the piston or adding a suitable number of thin washers there.

Re: And Now for the Twin

Posted: Wed Dec 30, 2020 7:52 pm

by Mike Rometer

Lopez Mike wrote: ↑Wed Dec 30, 2020 7:33 pm

Maybe do the tapered crosshead end first. The piston end can then be machined as near right as you can measure and then be adjusted, if needed, by either taking a bit more off of the shoulder that is against the bottom of the piston or adding a suitable number of thin washers there.

That could work Mike, and I have to say that taper socket would be my preferred method, it seems the most secure. I wonder what most others do?

Re: And Now for the Twin

Posted: Wed Dec 30, 2020 8:47 pm

by DetroiTug

Mikes,

I used this simple, effective and smidge ugly method to secure pins on the tug engine.

It's easy to make just a 1/8th inch slot across the pin