Page 12 of 16

Re: And Now for the Twin

Posted: Wed Dec 30, 2020 10:33 pm

by Lopez Mike

I think he's working on his piston rod, piston and crosshead. I like your valve gear solution but I don't think it would stand up to the the forces on the piston rod.

Mike

Re: And Now for the Twin

Posted: Thu Dec 31, 2020 9:46 am

by Mike Rometer

I've seen DT's method used a lot on hydraulic 'wrist' pins. I think it's quite neat. Yes I am looking at the piston rod to cross-head joint.

Re: And Now for the Twin

Posted: Thu Dec 31, 2020 6:47 pm

by DetroiTug

Mikes,

This is how I fixed the wrist pins. Use two set screws, one behind to lock it. That ensures that the pin will rotate in the bearings and not in the crosshead.

Fancy artwork like the advice is free

Re: And Now for the Twin

Posted: Thu Dec 31, 2020 11:35 pm

by dampfspieler

Hello Mike,

the crosshead bolts of the engine of my steam lorry are screwed and secured with a locknut. It works well last five years.

- PoP_W933kl.jpg (84.79 KiB) Viewed 34989 times

- PoP_W931kl.jpg (82.99 KiB) Viewed 34989 times

--

Dietrich

Re: And Now for the Twin

Posted: Fri Jan 01, 2021 2:51 am

by TahoeSteam

Mike, on our Doty the rod is threaded into the crosshead and a locknut secures it. Allows for fine adjustment of the clearance height when setting up. The piston end is a taper with a locknut.

Come to think of it, on all of our engines the piston rods are threaded into the crosshead and locked with a nut.

Re: And Now for the Twin

Posted: Fri Jan 01, 2021 3:55 am

by Lopez Mike

I'm not nearly as familiar with stationary and boat steam engine designs as I should be. I am very familiar with locomotive practice.

As you point out, one end at least should be adjustable and accessible. In railroad practice, though, the piston end is usually tapered with a lock nut and the cross head end tapered and cross pinned with a flat wedge shaped pin. Sledge hammers are involved! The manufacturing is done to a close enough standard that no adjustment of the clearances at the ends of the stroke is thought necessary. There are exceptions.

In the case of slide valve engines the common design is to have a cylindrical socket joint in the valve rod with a cross pin to lock the joint. Only disturbed for disassembly. The fine adjustment of the valve centering is done by removing a plug on the front of the valve chest for access to a threaded contrivance to adjust the relationship between the valve rod and the floating block that drives the valve. Much simpler to see than to describe, of course.

Locomotives live a dog's life compared to marine or stationary service. The designers have had to work towards connections that will NOT work loose under terrible wracking and vibration and high power loadings. It's not easy to develop twice the power of a medium sized ship and have it fit through a bridge or tunnel. Efficiency was often the looser.

Mike

Re: And Now for the Twin

Posted: Fri Jan 01, 2021 4:44 am

by DetroiTug

He did say ''piston rod'' didn't he?

Yes, it's just threaded in to the crosshead with a locknut on all my engines on cars and boat, Young and old. 1/2-20 and 3/8-24 threads.

I have to start paying better attention. A little embarrassing, oh well.

Re: And Now for the Twin

Posted: Fri Jan 01, 2021 9:16 am

by steamboatjack

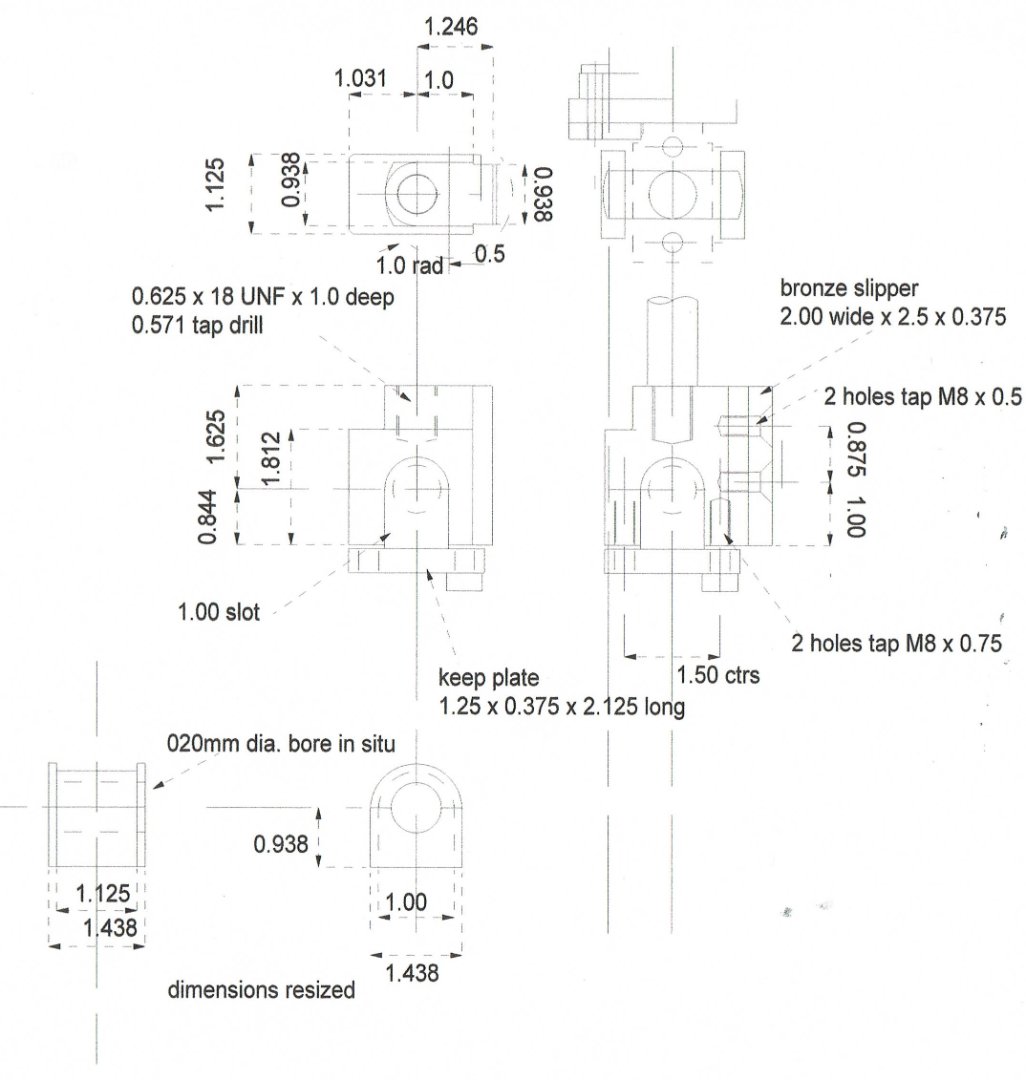

The correct name is a "crosshead pin bearing" known to sea going engineers as a "top end". below is a copy of the style I have used on all my recent built engines, using a pin which is fitted and dowelled to the conn rod, the bearing is adjustable and can be easily lubricated through the crosshead. I have used sealed rollers in the past with double style conn rods but these are of course wider and need lubrication holes through the pins. Lubrication of these bearings is essential and the clearance of the bearing fit should be the absolute minimum.

Regards

jack

- crosshead assy. (2).jpg (91.39 KiB) Viewed 34963 times

Re: And Now for the Twin

Posted: Fri Jan 01, 2021 11:08 am

by Mike Rometer

Cheers for all the above chaps!

I have, with my usual bent for '3.00 AM engineering', come down on the side of shouldered and threaded. The rod is 10mm so M8 should cut it. That will make it tight at the bottom and still adjustable at the piston end as Mike L. suggested, as those are lock nutted. All the others I have done have been tapered and pin locked, but with the benefit of more 'head room' in the cyl.

HNY to one and all! Let it be a better one.

Re: And Now for the Twin

Posted: Fri Jan 01, 2021 2:59 pm

by DetroiTug

Threading the piston rod into the crosshead without some means to lock it tight on the threads seems a less than optimal technique. If it loosens over time and it most likely would, re-tightening without disassembly would be nearly impossible.

On all the old steam engines I've worked on, the rod is threaded on with a locknut to prevent the rod from loosening and chucking on the threads. If it does come loose then it can simply be tightened with the locknut - really a jamnut.

Lubricated and Sealed bearings never need lubrication, that is the whole idea of them, it doesn't lose grease, so it never needs any. If it fails, replace it, I nor anyone else that have these types of bearings fitted have had one fail. They are rated for much higher duty than we impose on them. I don't like them because they are not traditional, but I cannot deny their exceptional performance.

Also, regarding the pistons on the old car engines I've rebuilt, the piston is an assembly of stacked discs with rings in between and each disc is threaded on the rod, then secured with a locknut. Then the end of the piston rod is peened to absolutely prevent the nut from coming off. Piston rod length adjustment is performed at the crosshead and secured with the jamnut and lockwasher.