Page 3 of 5

Re: US Navy Type-K VALVE

Posted: Wed Nov 13, 2013 1:51 am

by Lopez Mike

Oh, I know. It's just that I seem to have spent all to much time in my life flying along wondering what part of the plane was going to fall off next or heading into turn one at Daytona relying on my brakes for salvation from gross stupidity. Like being there at all!

Bart! The gods will strike you down for even thinking of plastic in a valve like that. It is somewhat like the stone carvers working on forever hidden details on a cathedral.

Mike

Re: US Navy Type-K VALVE

Posted: Wed Nov 13, 2013 4:37 am

by barts

Bart! The gods will strike you down for even thinking of plastic in a valve like that. It is somewhat like the stone carvers working on forever hidden details on a cathedral.

Actually, the plastic works really well for stuff that gets a lot of use.

In the valve, just drilling and tapping the end of the pin for a Allen head and washer straight in would be simple and rugged; a stainless button head cap and stainless washer would work well and keep things where they belong.

- Bart

Re: US Navy Type-K VALVE

Posted: Sun Aug 24, 2014 8:54 pm

by Rainer

Hello Boys,

it's me again - it did some excursus to other hobby's... Now it becomes cold outside and I started machining my two sets of Navy-K valves

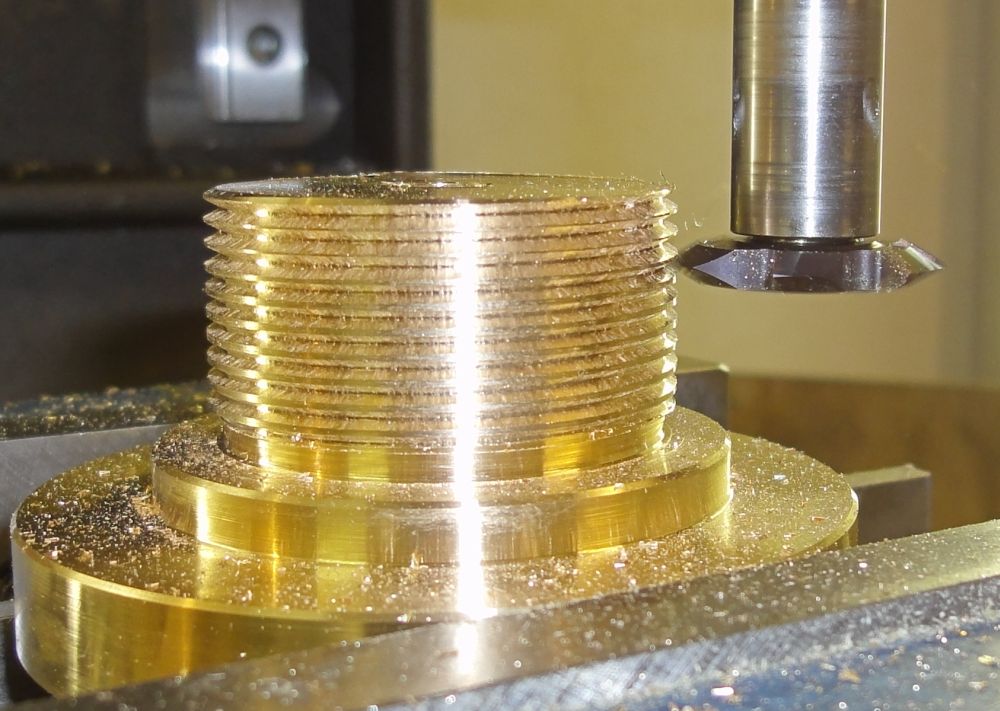

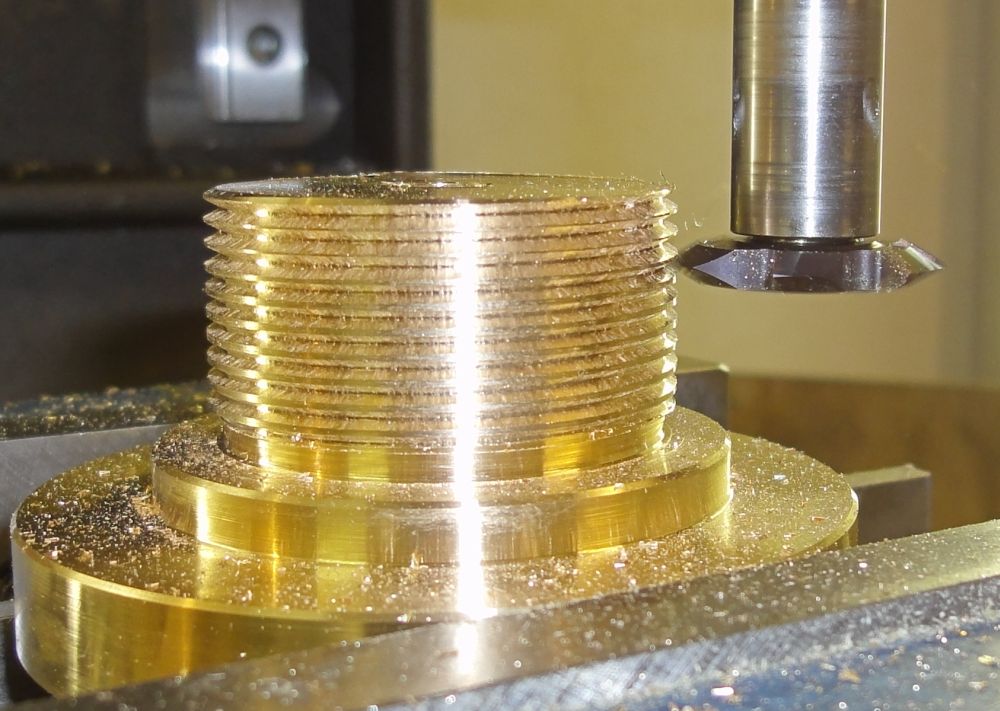

My home made CNC-mill is a big help with making such big threads. I had to learn all of this first. I changed from the original 1.5" - 16 TPI to M42 x 2 - nearly the same.

Movement frozen by the flash light. The special thread mill is spinning with 1000 rpm while it is circular and downwards guided around the bolt by CNC. Upper part is already ready machined. Lower part is missing 0.35 mm thread depth.

The body was machined with the same tool but software settings for inner threads.

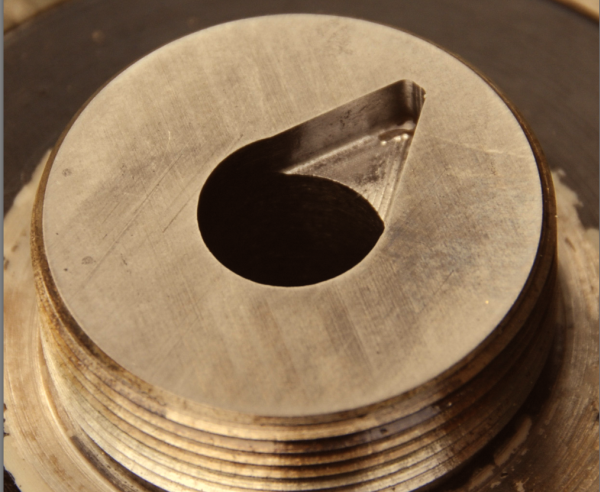

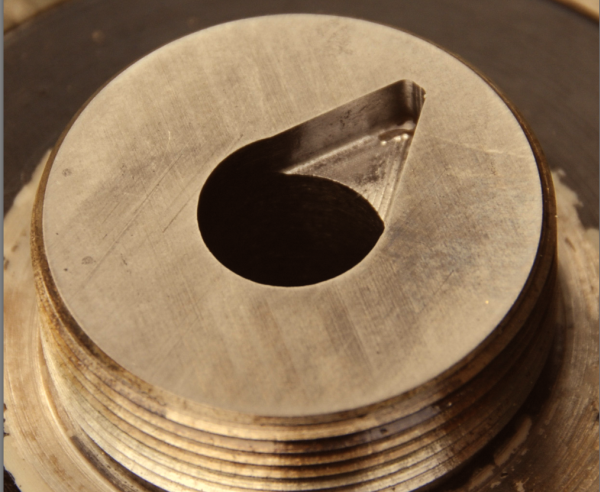

The flange and the body sits face to face against each other. This will secure the bolt orientation in the body and give me the opportunity to machine a V-shaped valve opening for best fine regulation.

With the set of castings I got some pictures also. This shows such a V-shaped opening - any comments about the best form for this? Has anyone else machined this set of castings already?

Re: US Navy Type-K VALVE

Posted: Sun Aug 24, 2014 9:16 pm

by Rainer

Here is a video of the milling process

[Youtube]

https://www.youtube.com/watch?v=zVDg-UQ ... e=youtu.be[/Youtube]

Re: US Navy Type-K VALVE

Posted: Mon Aug 25, 2014 3:11 am

by Lopez Mike

Wonderful. I would never have thought of cutting a thread that way.

But it strikes me as being like a joke where the light bulb is held stationary while the house is turned.

Re: US Navy Type-K VALVE

Posted: Mon Aug 25, 2014 4:31 pm

by Rainer

Lopez Mike wrote:- like a joke where the light bulb is held stationary while the house is turned.

You are right but I am happy to find someone to turn the house because how to machine a thread with this lathe?

It is powerfull and precise - but without any gears...

But anyway - did anyone machined this valve already and can tell me which shape of V-slot is the best?

Re: US Navy Type-K VALVE

Posted: Mon Aug 25, 2014 8:51 pm

by marinesteam

Rainer wrote:Hello Boys,

With the set of castings I got some pictures also. This shows such a V-shaped opening - any comments about the best form for this? Has anyone else machined this set of castings already?

Rainer,

Haven't started my casting set yet. I don't remember were it was mentioned, in the build instructions perhaps, that the V was added after the fact to give the throttle a bit more progressive opening. My guess is that Dave added the V detail and it worked so he didn't pursue the shape further.

You could stay "steel safe" and make the V narrower/shallower than in the prints and open it up after seeing if the throttle response is to your liking. I think the rate in which the area opens up is what is important and the current shape looks about right, not that that really means anything in a technical sense. My plan is to make mine look like the picture unless you find that something else works better.

Keep us posted with what you end up doing.

Ken

p.s. Nice job on the thread milling!

Re: US Navy Type-K VALVE

Posted: Mon Aug 25, 2014 10:55 pm

by Lopez Mike

For reference, I have a simple ball valve throttle and the opening rate from closed is quicker than I would like. Its opening rate can probably be approximated by one circle uncovering another. Model locomotives have used a rather long, narrow and shallow groove but they are plagued with poor traction and spinning of the wheels.

As Ken suggests, start small. It will still have full flow at full opening.

Re: US Navy Type-K VALVE

Posted: Tue Aug 26, 2014 10:18 pm

by Rainer

OK - thanks - for the suggestions!

Will start small and machine away a bigger grove from backside. I have to install it on my friends boat in the US during my autumn vacations. There I have to use a file to enlarge it - because there is no mill available. But anyway - with a file I can do and test it on the boat instantly...

Re: US Navy Type-K VALVE

Posted: Wed Sep 10, 2014 7:58 pm

by Rainer

Some progress:

I turned the house again