Page 4 of 5

Re: US Navy Type-K VALVE

Posted: Thu Sep 11, 2014 3:20 am

by TahoeSteam

Looks great Ranier.

Waiting anxiously for more updates on your boat and engine too!

Re: US Navy Type-K VALVE

Posted: Tue Sep 16, 2014 1:01 pm

by Wicwas Steam Works

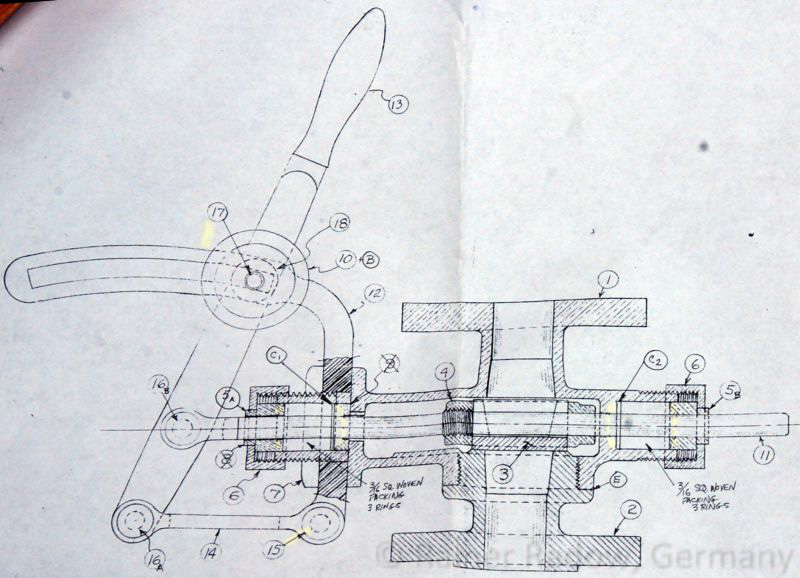

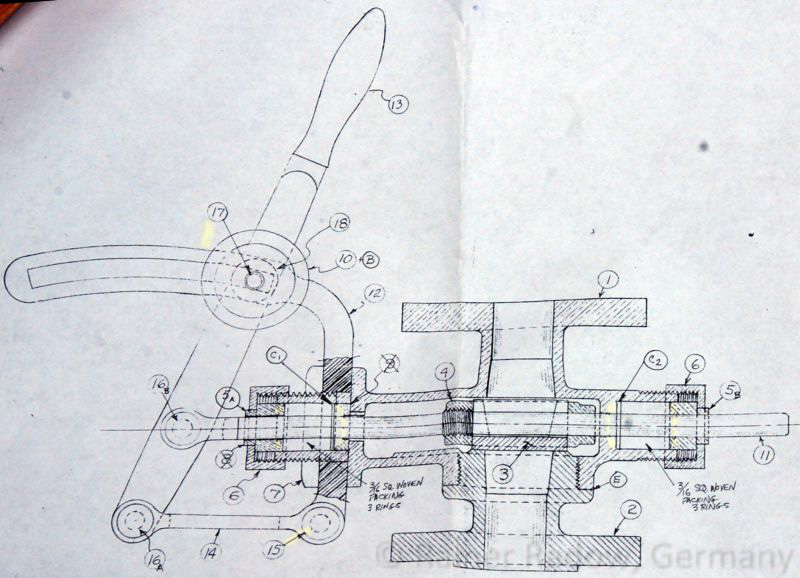

There has been some chatter about the "V" extension of the main port opening. The shape and depth shown in the builder's notes has worked well for 2 seasons in 2 boats. It allows a progressive opening and good control for low RPM operation. I do not recommend deepening the groove or cutting it all the way through.

H e l p!

Posted: Sat Oct 18, 2014 9:40 am

by Rainer

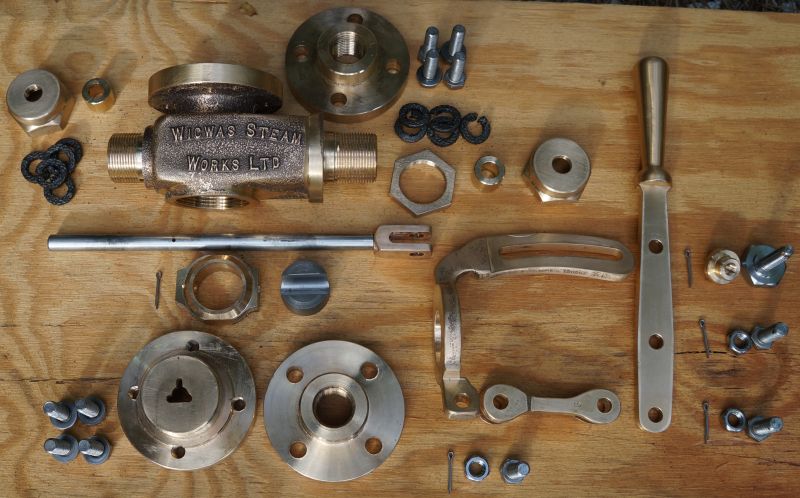

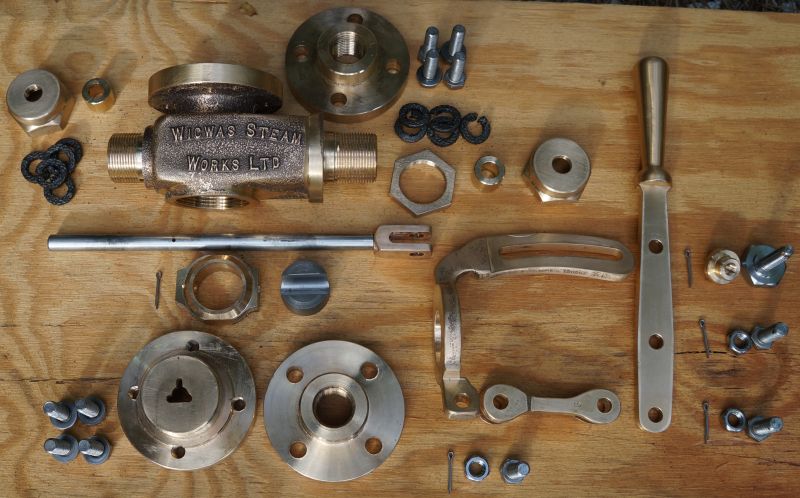

I did some more machining. This has to be ready next weekend because I have to bring it as a present to the USA...

I did the machining of the lever a little different than stated in the instructions.

All this was done by manual turning, file, sand paper... - have "to CNC" this lathe also some times...

Technical ready - need some more surface finish

Now I have to make the sliding part #3 guided by #4. Please have a look at the original drawing. For me this is not a good design to eliminate alignment problems of the valve rod #11 and the sliding surface of #2. To give some flexibility here you have to make a loose fit between #3 and #4 - but what fore do we have to make this massive part #4 if we have a loose fit here? Why not making it without the #4 just guided with a nut on #11 rod - like a D-valve.

Please tell me your thoughts!

No remarks to my question above?

Posted: Sat Oct 18, 2014 10:44 pm

by Rainer

No remarks to my question above?

Todays status - this quadrant is a lousy part - week and difficult to clamp. Lots of possible/necessary alignements.

All parts ready for assembly

Posted: Wed Oct 29, 2014 11:03 pm

by Rainer

All parts ready for assembly

Re: US Navy Type-K VALVE

Posted: Thu Oct 30, 2014 3:29 pm

by TahoeSteam

Looks great Ranier! It appears you left the quadrant as designed?

Re: US Navy Type-K VALVE

Posted: Thu Oct 30, 2014 10:04 pm

by marinesteam

It looks like you redesigned the actuation rod (part 11) to use a cotter instead of a thread to retain the throttle yoke (part 4). Tell us how assembly goes as it looks like it might be a bit difficult to get access during assembly. It certainly saves some work on the actuation rod.

Cheers

Ken

Re: US Navy Type-K VALVE

Posted: Fri Oct 31, 2014 8:56 pm

by Rainer

Yes, I did the quadrant as it was in the original design.

Yes, I changed the actuation rod #11 design. I like to use ready grind stainless rods for something like that. I am not able to machine a surface like that. Without the thread I don't have to do so. It was easy to pin it from the top and bend over the pin ends from the bottom.

If you drill the pin hole after you machined all the other parts you don't need the possibility which you get with a thread to change the open/close position.

Re: US Navy Type-K VALVE

Posted: Wed Nov 05, 2014 9:23 pm

by DetroiTug

Rainer,

Very nice work as usual.

To get a nice finish on shafting without a toolpost grinder, I leave about .001"/.02mm on the last pass which is light cut and slow feed and sharp tooling. Then use an emery strip of about 100 grit to bring it to dimension. Then polish with maroon scotch brite pad. It will shine like a mirror.

https://www.fastenal.com/web/products/details/0281639

-Ron

Re: US Navy Type-K VALVE

Posted: Wed Nov 05, 2014 10:23 pm

by Mike Rometer

To improve the finish of emery strip, apply some oil to it. That gives a nice bright finish which is easier to polish.