Page 1 of 1

A Funny Looking Slide Valve

Posted: Sat Mar 26, 2022 2:28 pm

by Kelly Anderson

The original low-pressure slide valve in my launch engine needed to be replaced this spring due to heavy wear in the cast in T-slot that connects it to the valve stem, so I hogged the new one from G2 cast iron plate, and to assist with potential wear on the bottom faces of the T-slot, I made those pieces and the block at the top of the valve stem from 4140 steel. The valve stem is Monel.

The dead-end shallow slots along the sides of the valve seat are a feature sometimes seen in locomotive slide valve to allow oil to reach these normally dry areas of the valve.

This engine uses inside admission slide valves, the only time that I have ever heard of such an arrangement. To hold the valve against the seat, a generously sized, spring-loaded balancing piston is provided. As I have said, the designer of this (originally an automobile) engine threw every far-out design feature that he could think of into this project.

New valve stem

Seat side of new valve

Balancing side of new valve

More photos to follow.

Re: A Funny Looking Slide Valve

Posted: Sat Mar 26, 2022 2:36 pm

by Kelly Anderson

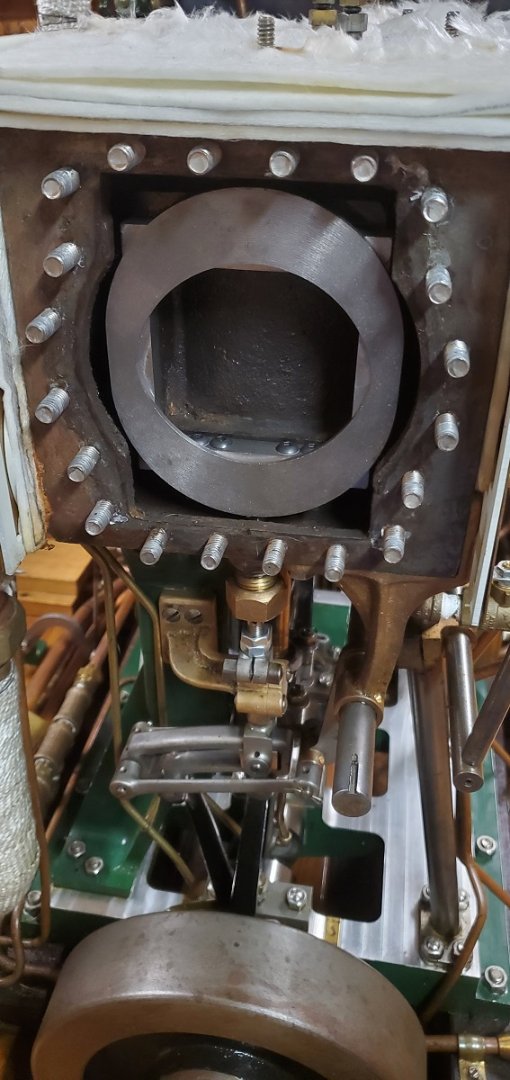

New valve assembly

Balancing piston

- valve installed and set.jpg (102.08 KiB) Viewed 19537 times

Valve installed and set

Re: A Funny Looking Slide Valve

Posted: Sat Mar 26, 2022 5:21 pm

by fredrosse

Excellent work, as usual from you. The oil slots on the slide valve is new to me, although I have only been involved with the study of steam engines for 70 years now.

Re: A Funny Looking Slide Valve

Posted: Sun Mar 27, 2022 6:16 pm

by Lopez Mike

Interesting that there are still engines still being built with slide valves. I suppose we have Stuart Turner to thank for that.

~1840 to 2022. Over an 180 year run. Not bad.

I'm reminded of the cry of Tevye in Fiddler on the Roof. "Tradition!!!"

Mike

Re: A Funny Looking Slide Valve

Posted: Mon Mar 28, 2022 12:29 am

by DetroiTug

Slide valves go back further than that. Rocket built in 1829 had them. They have their advantages, they'll put up with more abuse, lower maintenance. The big one is their ability to lift off the face in a carry over event. When running a hotwell the water is more tightly managed. For operators manually controlling the bypass valve, over filling the boiler is much more likely, I know that from experience. Practically all the early steam cars used slide valves. Under 200 psi they work good and are very easy to get along with.

A real good book on Amazon is titled Before Rocket by Anthony Dawson. It covers rail engines built prior to Rocket.

Re: A Funny Looking Slide Valve

Posted: Mon Mar 28, 2022 5:07 pm

by barts

Despite their deficiencies, note that basic slide valves require minimal precision equipment to manufacture, esp. in larger sizes. The interior cavity can be as-cast. The outside can be the same, or filed to the desired dimension. The sliding surfaces could have been scraped into whatever degree of fit was desired. The valve ports in the cylinder can be as cast, or hand worked. To renew a slide valve, all that is needed is insure that the sliding surfaces are smooth and flat and to inspect the valve mechanism to insure that valve can rest against the port face.

The slide valve in Otter's original engine (a converted refrigeration compressor 2 cylinder single acting 2"x2.5") gave good service despite significant abuse w/ mildly superheated steam w/ the original boiler (a $50 special) and excessive pressure for a slide valve (180 psi) from the new boiler.

For piston valves to give satisfactory service over a length of time, rings and thus a cast iron sleeve with ports need to be used. Otter's current engine (built in 1892 or so best I can determine) has a piston valve w/o rings, and it has worn significantly over actually little service after I renewed it w/ line boring the piston valve bore and turning a new bronze valve (matching the original). The old valve & bore were very obviously worn, and a previous owner had attempted to build up the old valve with some sort of soft alloy.

If Rainbow's HP cylinder had a piston valve, the original valve guides would have been sufficient, most likely, though. Short engines with unbalanced slide valves are hard on valve guides.

When I retire and after Rainbow is launched again, I plan to fit a ported sleeve and a piston valve w/ rings to Otter's engine.

- Bart

Re: A Funny Looking Slide Valve

Posted: Mon Mar 28, 2022 9:10 pm

by DetroiTug

"unbalanced slide valves are hard on valve guides''

Equally important is the centerline of the valve rod should be as close as practical to the plane of the cylinder face. This imposes a more a linear force between the two rather than a tendency to rock the valve on it's ends.

Re: A Funny Looking Slide Valve

Posted: Mon Mar 28, 2022 9:29 pm

by barts

Equally important is the centerline of the valve rod should be as close as practical to the plane of the cylinder face. This imposes a more a linear force between the two rather than a tendency to rock the valve on it's ends.

This is where the designs that have a square or rectangular piece that surrounds the actual valve are best, since the ones that attach the valve directly to the valve rod must of course have the valve rod above the center (exhaust) cavity.

An upper guide for the valve rod and pushing the valve from the ends can help here as well, w/o the difficulties of raised faces on the ports to leave room for the stuffing box for the valve rod in the steam chest.

- Bart