Page 1 of 3

Fuel pump as condensate pump - experiences

Posted: Thu Sep 18, 2025 10:44 am

by dampfspieler

Hi,

in a new project i want to use a DELCO fuel pump as condensate pump, like done at the plants of STUART Cygnet or Swan. Are there any experiences with that configuration?

Regards

Dietrich

Re: Fuel pump as condensate pump - experiences

Posted: Thu Sep 18, 2025 9:54 pm

by barts

in a new project i want to use a DELCO fuel pump as condensate pump, like done at the plants of STUART Cygnet or Swan. Are there any experiences with that configuration?

I remember reading about these kind of installations in the 1990s in Steamboating.... there's some more recent discussion here if you have facebook:

https: //

www.facebook.com/groups/steamboatassoci ... 912192503/

- Bart

Re: Fuel pump as condensate pump - experiences

Posted: Fri Sep 19, 2025 3:36 am

by dampfspieler

Hi Bart,

thank you so much. It was very helpful an i have asked Dave for help with the modification notes.

Dietrich

Re: Fuel pump as condensate pump - experiences

Posted: Mon Nov 10, 2025 8:28 pm

by PeteThePen1

That is an interesting idea. Also having a Cygnet engine and also thinking about condensing it might be something for me to adopt. There do seem to be lots of ACDelco pumps available on eBay at quite reasonable prices.

I look forward to seeing how you get on with the idea.

In this part of the world (Cymru) I am fighting with a new Raspberry Pi 5 which refuses to see the keyboard under the GUI but will happily work with it at OS level. I think the Raspberry Pi Connect system that allows one to 'control' the Pi from another computer is going to provide a fix. Next up is to install Python and get the two thermocouples for the mono-tube boiler sending me some figures. The untimate aim is to have the Pi control the electric feed pumps using the thermocouple data. Once I have sime progress I will post up some details. The whole story so far is to be found on [

https://mono-tube.org.uk/index.php/tech ... ight-canoe]

Regards

Pete

Re: Fuel pump as condensate pump - experiences

Posted: Tue Nov 11, 2025 7:48 am

by dampfspieler

Hello Peter,

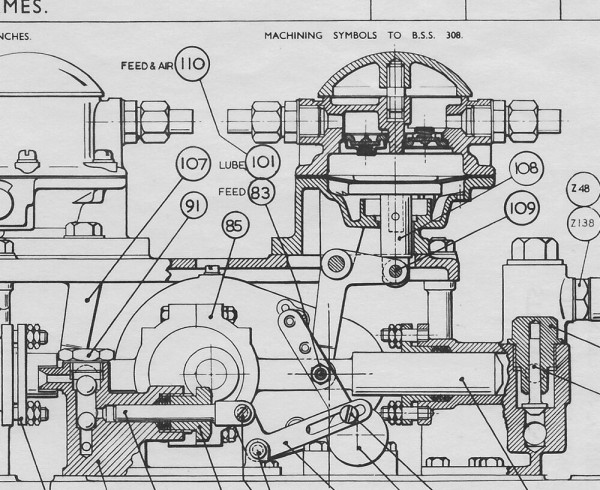

yes it is. However, implementing the modifications is somewhat challenging, especially since it would likely be sensible to build a pump unit with all the necessary pumps (condensate, feed water, steam lubricant, circulating for the condenser), as can be seen in the pictures below.

neccesary modifications

- Modifications to the pump

- Air Pump Mod.jpg (101.19 KiB) Viewed 34590 times

The pumps plant of a swan

- StuartTurner_Duplex_ME_FeedAirPumps_1.jpg (139.16 KiB) Viewed 34590 times

- StuartTurner_Duplex_ME_FeedAirPumps_2.jpg (145.75 KiB) Viewed 34590 times

------

Dietrich

Re: Fuel pump as condensate pump - experiences

Posted: Tue Nov 11, 2025 7:56 am

by dampfspieler

Hello,

since only three images are allowed in one post, here's another picture showing the pump gearbox. The machine speed is reduced by half to ensure the pump valves operate reliably. Above 500 revolutions per minute, the pump valves require slightly more effort.

- StuartTurner_Duplex_ME_FeedAirPumps_5.jpg (135.04 KiB) Viewed 34587 times

----

Dietrich

Re: Fuel pump as condensate pump - experiences

Posted: Sat Dec 06, 2025 4:59 pm

by PeteThePen1

Thanks for posting up the three pictures. It is nice to see such a beautifully engineered machine. I am, as usual, mystified by the castings at the lower level on each side which look to me like pump body castings, not to mention the little pump in the middle at the same level. The black castings are, I assume, the AC Delco items but how they relate to the other bit remains a mystery. Perhaps we need you and Dave to write up an article for Funnel that explains it all.

Here the Raspberry Pi is being 'forced' into working by installing an older version of the OS which is recognised as being robust. It has taken too much time but today we got keyboard and mouse working in GUI and CLI modes as well as having SSH to the PC via a cable from the Ethernet port to a plug in Ethernet adaptor on the PC. With luck it should be possible to plug back in the SX6675 breakout boards and interpret the readings from the two thermocouples next week. Perhaps 'fly by wire' steam boilers are not quite such a simple idea after all!

Good wishes to all you fellow Steamers for the Festive Season.

Regards

Pete

Re: Fuel pump as condensate pump - experiences

Posted: Sun Dec 07, 2025 8:54 am

by dampfspieler

Hi Peter,

yes, there are three types of pumps in the pump unit. At the top are the two condensate pumps (modified DELCO fuel pumps), at the bottom on the outside are the boiler feed pumps, and in the middle is the pump for the cylinder oil.

The pumps are driven by a 2:1 reduction gear, so that even at engine speeds of 900–1,000 rpm, the pumps operate at a maximum of 500 strokes per minute. Mushroom valves are installed in the boiler feed pumps.

I have had very good experience with such valves on my MARTIN steam truck at pump speeds up to 1,500 rpm. However, they are slightly modified there; they have O-rings as sealing elements and are pressed into place by light bronze springs with slight preload.

Because of the copyright on STUART's drawings, I will only show my own, but please be patient, as there are unfortunately still a lot of other projects to complete.

---------------

Dietrich

Re: Fuel pump as condensate pump - experiences

Posted: Wed Jan 14, 2026 7:17 pm

by dampfspieler

Hi,

- Details of the Pumps

a cross-sectional view of the condensate, boiler feed, and cylinder oil pumps.

The work on the diaphragm pump is quite extensive. The first step is to remove the original lever drive and modify the remaining components to a greater or lesser extent.

This is the first time I've seen this design for the boiler feed pump valves. They are vertical mushroom valves, which I will implement using O-rings as sealing elements. Because the pressure acts on the valve mushrooms from above, springs to assist closing are unnecessary. Slightly higher demands are placed on the concentricity of the valve guide and the valve seat. It is important to provide the shaft with a wrench flat to prevent it from seizing.

The pumps are driven by a 2:1 reduction gear from the crankshaft of the steam engine. One condensate pump and one boiler feed pump are each driven by an eccentric mechanism.

---------

Dietrich

Re: Fuel pump as condensate pump - experiences

Posted: Wed Jan 14, 2026 7:54 pm

by dampfspieler

Hi,

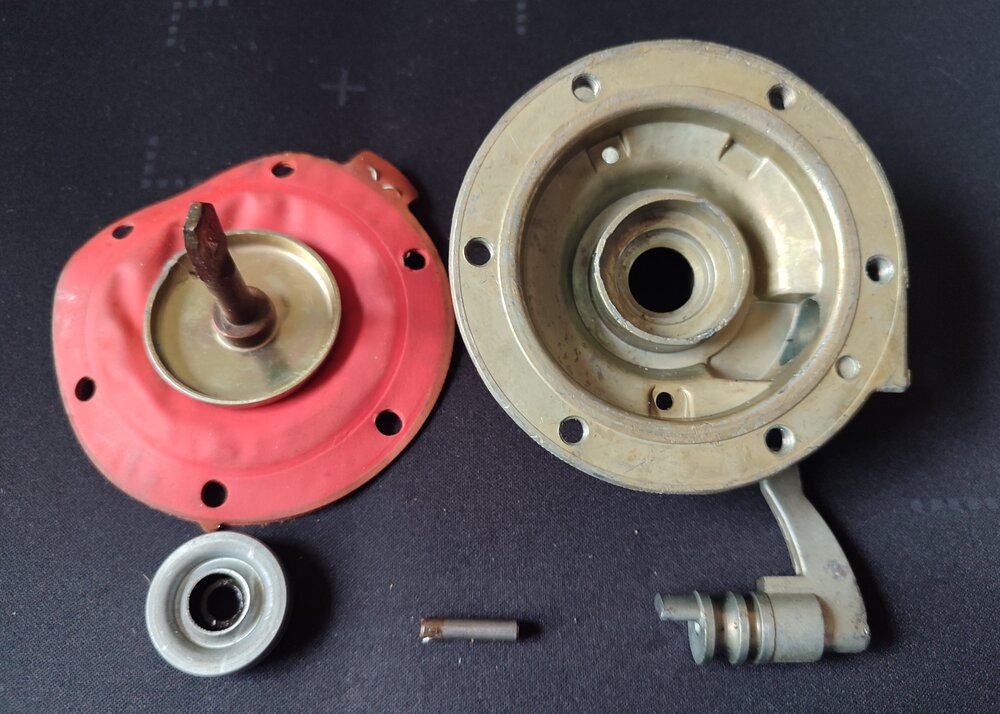

- the disassembled lower part

- STUART_MembPu003.jpg (140.15 KiB) Viewed 11167 times

the tappet was guided in a combined seal/guide, which will be removed and replaced by a suitable guide bushing for the new diaphragm tappet. The lever for manual operation will be superfluous in the future and will be redesigned into a simple plug (the prongs will be removed) which is held by the original locking pin.

- The upper part of the pump housing

- STUART_MembPu008.jpg (179.79 KiB) Viewed 11167 times

The top can be used without any alterations.

- the parts of the drive

- STUART_MembPu005.jpg (128.09 KiB) Viewed 11167 times

The individual parts of the drive, the lid seal and the sealing cover of the pressure valve chamber.

-----

Dietrich