Patternmaking is good fun and very rewarding . But it can be hard to find up to date and straightforward information on how to do it in the home workshop, Steam cylinder patterns seem to be a particular problem, and there is a perception that they are very difficult. For one-offs or small batch projects it needn’t be so. You will see that I can neither attempt technical drawings, or any woodwork beyond the very basic. The main tools I use are a small bandsaw and a disc/belt sander, also my metalworking lathe so look away now if you don't approve!

The cylinder is a start on a replica of a very nice vintage single engine I was surprised to buy on ebay. Surprised because there were no other bids! A very straightforward design of 2.25” x 3.5” and would suit an 18 to 19 foot boat.

The foundry will use the patterns to make impressions in sand in two part split moulding boxes, then draw them out. For each part, the patternmaker has to think about where the parting line in the sand would best lie, and how the pattern can be removed without damaging the sand. Simple suitable shaped patterns can be made in one piece, and the parting line will be placed at the widest point, like this vase shaped example.

The cylinder top cover is a good place to start.

It can be made in one piece. The casting will be machined all over, and the aim of the pattern is simply to give enough material, and perhaps help the workholding. I sketched a pattern layout. The finished machined size is in red, and the pattern outline in black. I’ve added machining allowance all over and shown exaggerated taper. The taper changes direction at the parting line.

Th pattern is three discs, made from ply. The discs were marked out with compasses, rough sawn to shape and finished on the disc sander. My table doesn’t tilt up the way, so a piece of wood lying on it gave the taper.

The three pieces were drilled ¼” at their centre and a steel pin pressed in to help location while the PVA wood glue set. The outside corners were sanded to remove sharp edges. Next, I'll fillet the inside corners with car body filler and the pattern will be ready for final sand and varnish or paint. I'll add a photo shortly.

Moving on to the valve chest...The valve chest on the vintage engine has an integral cast on cover. This is not ideal for access to check valve settings, so I’ll make the copy with a more normal separate cover. An oval boss at the bottom end takes studs for the valve rod gland. At the top end is a screwed in bronze support for the valve rod tail, however this is quite loose, so I’ll alter this too, by making it part of the casting in the replica.

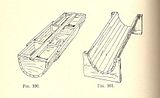

The chest is 1 ¼” deep, which would be quite a deep hole in the middle to deliver by tapering the sides, so is best cored out. A core is a block of special sand that is made separately and placed in the mould once the pattern has been withdrawn. The pattern is made with projecting pieces to suit called core prints – these make impressions in the mould sand that the core slots into. This engraving shows a cored out bush in the mould.

The valve chest can be considered as a rectangular belt of metal wrapped around a large hole. I decided to split the pattern along the line of the ruler shown here.

To withdraw from the mould the chest ends will need a little taper. These faces will not need machined. The front and back mating faces of the chest where it joints to the cylinder and the cover will need machining allowance and taper.

The pattern was made from yellow pine, offcuts from my new boat's floorboards. The two halves were drilled and located together loosely with two quarter inch steel pins. The oval gland boss has still to be added where drawn on the end, and also the round valve rod tail support at the other end.

To make the gland boss, two rectangular offcuts of mahogany were dry screwed together, held in the four jaw chuck and a round neck turned. The oval is marked on the end.

The next step is to form the oval with filing buttons.

I'll progress the core box too and post this next, them move on to the cylinder. John