Howdy All,

Is anyone using a steam eductor instead of a vacuum pump on the exhaust side of their engine ? I will be working on the plumbing for the closed loop system over the winter and it occurred to me that if I put an eductor in line somewhat down the exhaust from the engine that i could pull a vacuum on the engine and still condense the steam am using to do so.

thoughts ?

jon

Steam Eductor on Closed system

-

JonRiley56

- Full Steam Ahead

- Posts: 340

- Joined: Sat Oct 08, 2011 12:58 am

-

steamboatjack

- Full Steam Ahead

- Posts: 283

- Joined: Fri Nov 20, 2009 8:02 am

- Boat Name: grayling

- Location: Cumbria U.K.

Re: Steam Eductor on Closed system

Jon

This would be in effect an air ejector,I thought about this some time back for use with a uniflow engine where it is an advantage to have a vacuum for starting the engine. Usually air ejectors have the exhaust cooled/condensed by a unit which then utilises the heat for feed heating, I would imagine condensing it with the engine exhaust would be rather wasteful of energy for no real gain other than for starting.

Regards Jack

This would be in effect an air ejector,I thought about this some time back for use with a uniflow engine where it is an advantage to have a vacuum for starting the engine. Usually air ejectors have the exhaust cooled/condensed by a unit which then utilises the heat for feed heating, I would imagine condensing it with the engine exhaust would be rather wasteful of energy for no real gain other than for starting.

Regards Jack

- Rainer

- Full Steam Ahead

- Posts: 306

- Joined: Sun Nov 22, 2009 5:42 pm

- Boat Name: Emma and Molly

- Location: Hannover, Germany

- Contact:

Re: Steam Eductor on Closed system

The vacuum pump does not produce the vacuum.JonRiley56 wrote:an eductor in line ... that i could pull a vacuum

The vacuum will be produced by the condensing process of the steam at the cold surface of your condenser.

The so called vacuum pump is mainly a water pump to remove the water from the condenser room.

If your condenser is big enough, you even could go without pump for a while till the condenser will be full of condensate.

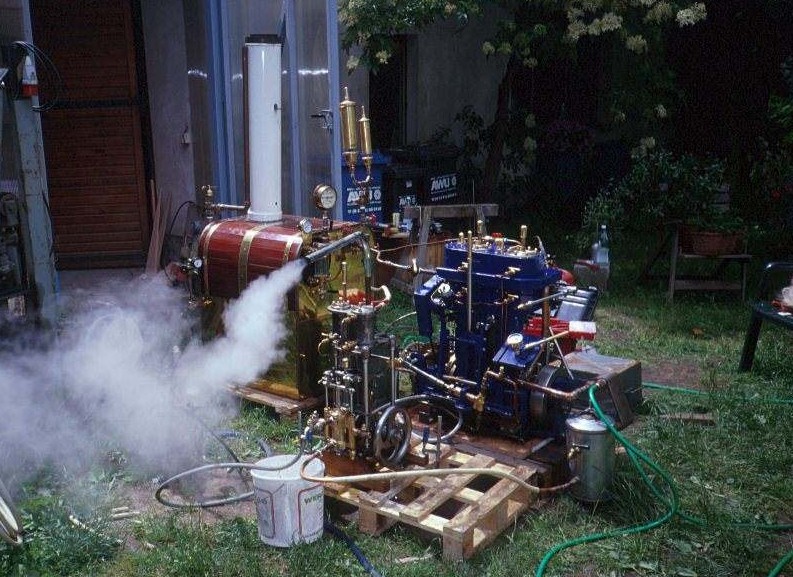

I have made this trial with a friends engine. At the right of this picture you can see a green hose coming from the gardens well going into a plate condenser (also coming out at the other side). This condenser takes the exhaust from the big blue machine. The condensate was running out of the condenser by gravity into the closed round stainless barrel (former bar coffee maker). This was a closed system (not a loop!) and the vacuum was build quite good till the coffe maker was full.

To remove the condensate from the coffemaker we used the pump at the "smal" single in front. This is also where the exhaust comes from. This system was set up to explain, that you don't need a vacuum pump to get a vacuum - the second engine was only used to make it german over-engineered, to irritate the Russians but mostly to have fun with the steam.

Close up

A vacuum pump adittional removes some "Air" which is trapped in the condenser.

If you would try to build up the vacuum only by a pump you would need lots of steam to finish the job!

Rainer

www.steamboating.de

www.steamboating.de

- fredrosse

- Full Steam Ahead

- Posts: 1926

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Steam Eductor on Closed system

In theory, you do not need a vacuum pump, but if you have valve stem packings that leak in air, or piston rod packings, etc, then air gets into the system and eventually destroys the vacuum. Packing glands that are always at positive pressure will not allow air into the system, but most small steamboats do not have these features, so a vacuum pump is needed.

Large plants use steam jet air ejectors typically, however in very small scale a piston type vacuum pump will work much better, and require much less steam to provide this power. The reciprocating vacuum pump can also be made to pump out the condensate from the condenser, and is then called a "wet vacuum pump". This arrangement is really the most practical for our small steam plants.

Large plants use steam jet air ejectors typically, however in very small scale a piston type vacuum pump will work much better, and require much less steam to provide this power. The reciprocating vacuum pump can also be made to pump out the condensate from the condenser, and is then called a "wet vacuum pump". This arrangement is really the most practical for our small steam plants.

-

JonRiley56

- Full Steam Ahead

- Posts: 340

- Joined: Sat Oct 08, 2011 12:58 am

Re: Steam Eductor on Closed system

Thanks Guys !!!

Rainer, that is an impressive looking setup, I think with a couple of changes you could have a nice Cappucino Machine......

Fred, what kind of pump would you suggest I use ? It would seem like I need to be able to run it dry.

jon

Rainer, that is an impressive looking setup, I think with a couple of changes you could have a nice Cappucino Machine......

Fred, what kind of pump would you suggest I use ? It would seem like I need to be able to run it dry.

jon

- fredrosse

- Full Steam Ahead

- Posts: 1926

- Joined: Fri Nov 20, 2009 5:34 am

- Boat Name: Margaret S.

- Location: Phila PA USA

- Contact:

Re: Steam Eductor on Closed system

I made my wet air pump from a pneumatic cylinder, and it has been stroking away for two full seasons, running dry most of the time, as I have not yet installed my condenser. I currently use this "wet vacuum pump" as a general service water pump, filling my feedwater tank while underway, or as a bilge pump on occasion. It works OK, and will draw 22 inches vacuum if I plug off the suction connection and attach a vacuum gauge.

The check valves are made from rubber washers, and the piston is made with an O-ring cylinder seal, and several small ports that the rubber washer seats against to act as a check valve on the upstroke of the piston. You could use ordinary swing checks mounted on the cylinder's port for inlet and discharge check valves. This would work OK as long as speed is kept down to about 100 - 150 RPM. I suspect this is about the same speed that would be ideal for your Hypro pump, but I do not have the hypro pump nameplate data yet.

I have heard of steamboaters using the old style (camshaft actuated) automotive diaphragm fuel pumps for wet vacuum pumps, these are inexpensive and will work at higher speeds such as your engine RPM, 400 - 500. Worth a try.

Sent you a PM also

The check valves are made from rubber washers, and the piston is made with an O-ring cylinder seal, and several small ports that the rubber washer seats against to act as a check valve on the upstroke of the piston. You could use ordinary swing checks mounted on the cylinder's port for inlet and discharge check valves. This would work OK as long as speed is kept down to about 100 - 150 RPM. I suspect this is about the same speed that would be ideal for your Hypro pump, but I do not have the hypro pump nameplate data yet.

I have heard of steamboaters using the old style (camshaft actuated) automotive diaphragm fuel pumps for wet vacuum pumps, these are inexpensive and will work at higher speeds such as your engine RPM, 400 - 500. Worth a try.

Sent you a PM also

- Attachments

-

- 1.5 x 2.625 inch wet vacuum pump for walking beam engine

- Engine WetVacuumPumpParts small.jpg (42.69 KiB) Viewed 9638 times

-

steamboatjack

- Full Steam Ahead

- Posts: 283

- Joined: Fri Nov 20, 2009 8:02 am

- Boat Name: grayling

- Location: Cumbria U.K.

Re: Steam Eductor on Closed system

Thinking about your idea some more, I think an eductor fitted after the condenser may work, it would have to be big enough to handle the condensate and air, The steam consumption would probably be excessive compared with the energy used by an engine driven air pump. Also the degree of pressure reduction gained by a single stage eductor is not great, most high vacuum air ejectors are two stage.

Air pumps should be like the one above, vertical single acting so that the head of water in the upper parts help seal the pump, unlike a feed pump the clearance volumes should be kept to a minimum.

The exception to vertical is the “Dave Fogg” pump found in steamboats & modern steam launches March 1963 page 25, this has zero clearance so can be horizontal.

Hypro pumps specs can be found on:-

http://www.hypropumps.com/fileattachmen ... _pumps.pdf

regards

Jack

Air pumps should be like the one above, vertical single acting so that the head of water in the upper parts help seal the pump, unlike a feed pump the clearance volumes should be kept to a minimum.

The exception to vertical is the “Dave Fogg” pump found in steamboats & modern steam launches March 1963 page 25, this has zero clearance so can be horizontal.

Hypro pumps specs can be found on:-

http://www.hypropumps.com/fileattachmen ... _pumps.pdf

regards

Jack